Method and apparatus for reducing diesel engine microparticle matter exhaust and apparatus

A technology for particulate matter and diesel engines, applied in the direction of mufflers, exhaust devices, mechanical equipment, etc., can solve the problems of cracking of filter body, large size of filter body, damage, etc., reduce the possibility of cracking and scrapping, reduce system cost, Good for maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

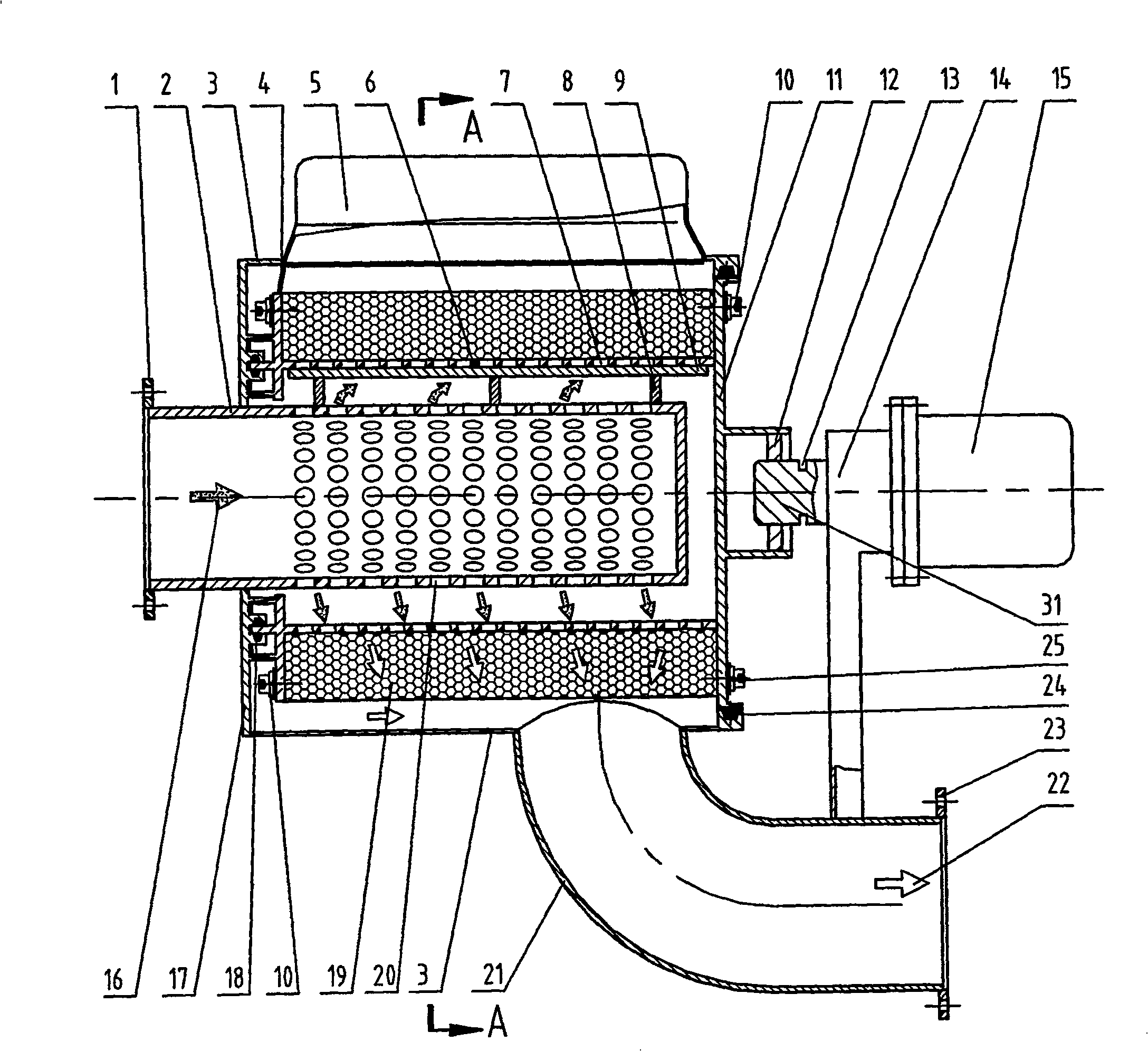

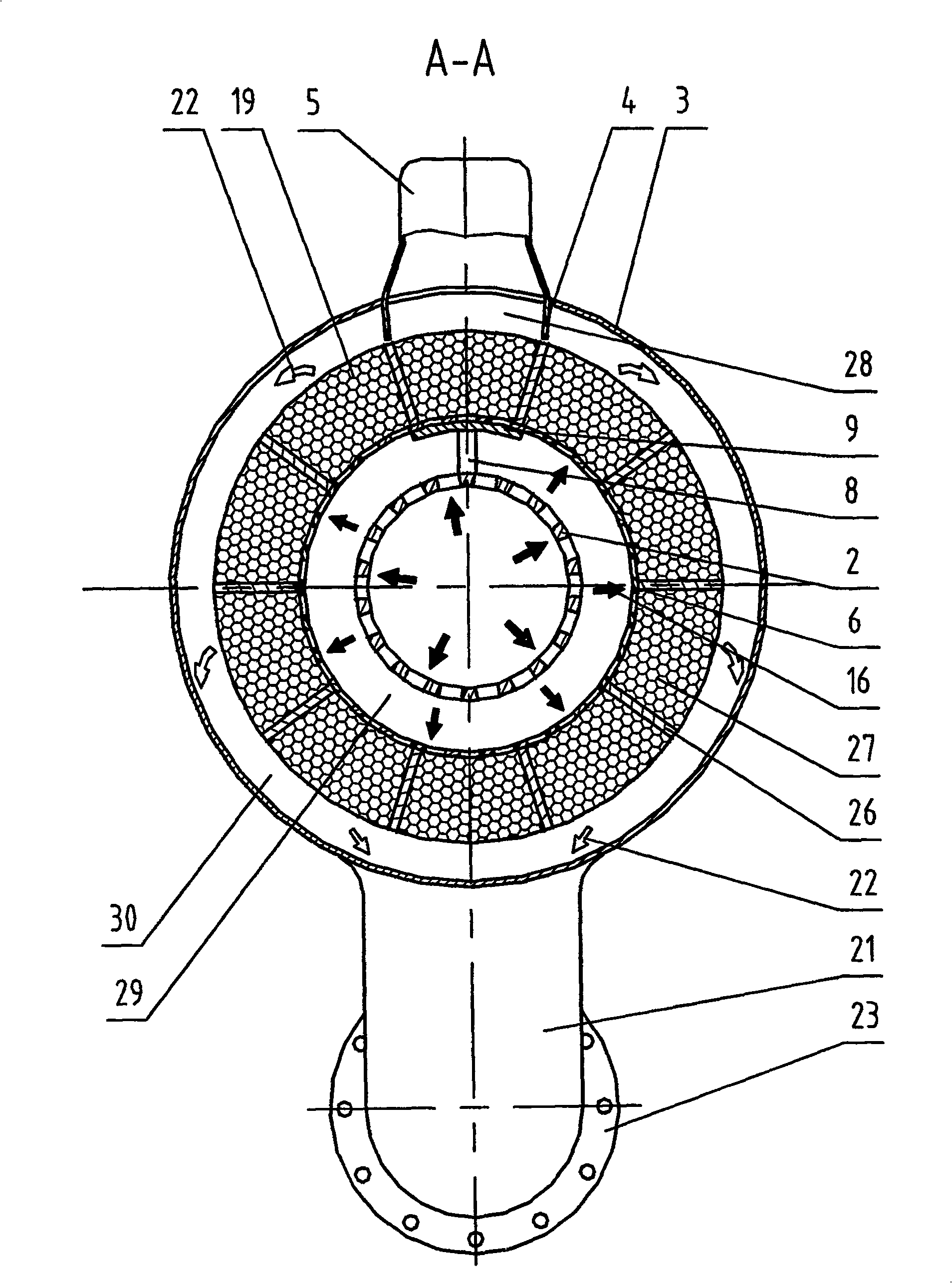

[0040] see figure 1 and figure 2 The structure of a kind of device that realizes the method of the present invention is that it has an exhaust gas introduction pipe 2 that is an air inlet end and the other end is a closed end, and the exhaust gas introduction pipe 2 that has an air flow passage 20 on the pipe wall is provided with an exhaust gas collection cover. 3. Between the exhaust gas introduction pipe 2 and the exhaust gas collection cover 3, a cylindrical support 6 with an air flow passage 7 on the cylinder wall is provided; at least four identical filter units 19 are installed on the cylindrical support 6 and A cylindrical filter body 27 is formed, and a partition plate 26 is arranged between every two adjacent filter units 19. There is an annular gap 29 between the cylindrical support 6 and the exhaust gas introduction pipe 2, and the cylinder There is an annulus 30 between the shaped filter body 27 and the exhaust gas collection cover 3; the exhaust gas collection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com