Visible light micro-nano reactor membrane for selective removal of ammonia nitrogen, its preparation method and application

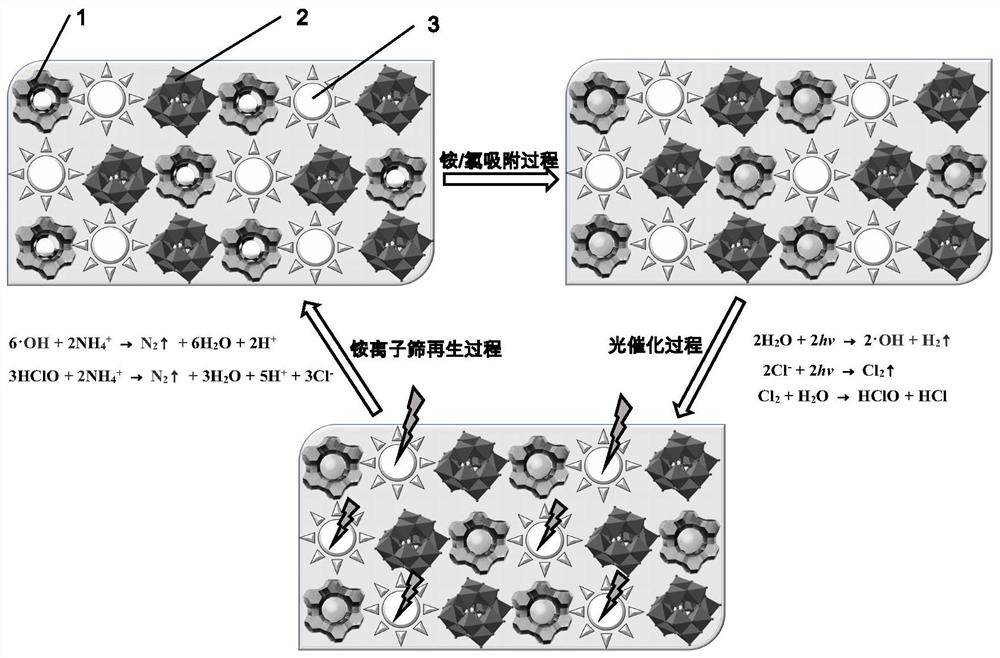

A micro-nano reactor and selective technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the difficulties of in-situ real-time regeneration, low selectivity of ion exchangers, and difficult treatment of regeneration solution, etc. To achieve the effect of stable water output, strong selective adsorption capacity and continuous regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

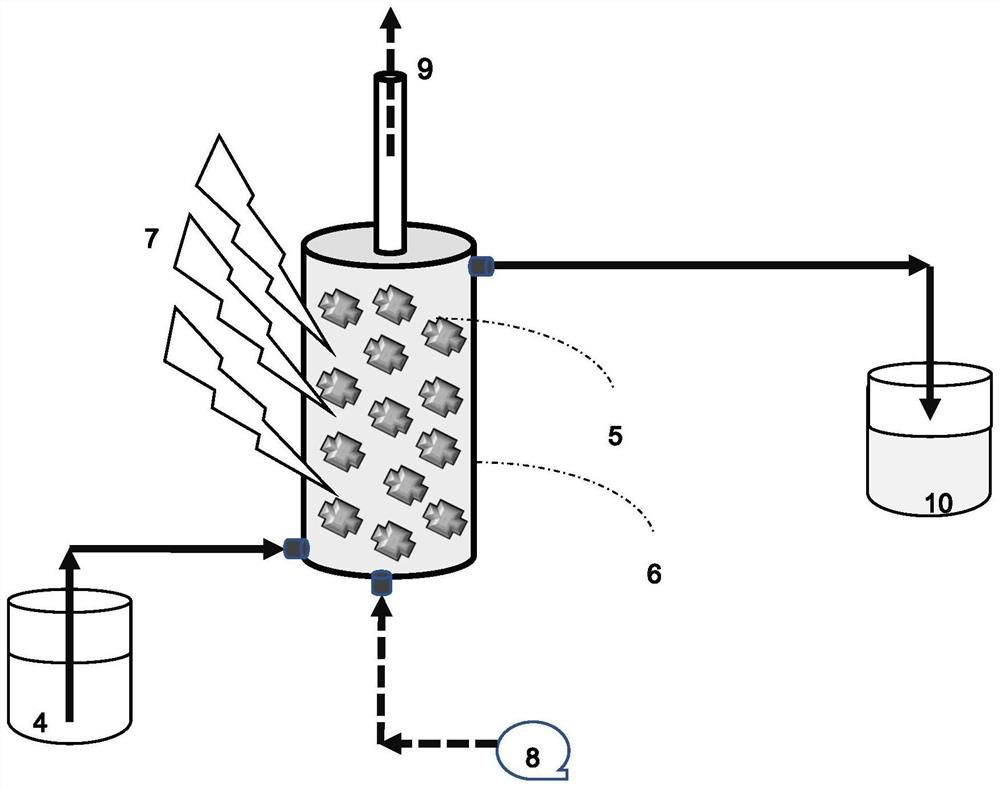

Method used

Image

Examples

Embodiment 1

[0042] Example 1 Preparation of visible light micro-nano reactor film

[0043] 1. Preparation of calcium aluminosilicate hydrate as a chloride ion adsorbent

[0044] In terms of molar ratio n(Ca):n(Al):n(Si)=4:1:2 Weigh calcium nitrate, aluminum nitrate and sodium silicate, prepare calcium nitrate with a concentration of 4mol / L with deionized water respectively Solution, 1mol / L aluminum nitrate solution and 2mol / L sodium silicate solution are 500mL each, mix the three solutions and stir for 3-5h under the condition of strong mechanical stirring at a speed of 100-500rad / min, then add 1mol / L sodium hydroxide solution adjusted the pH of the reaction system to 13.5. The reaction system was sealed and placed in a constant temperature water bath, and reacted at a constant temperature at 70°C for 120 hours. The obtained precipitate was washed 5 times with deionized water, and then the solid phase obtained after suction filtration was placed in an oven and heated at 55°C. After dryi...

Embodiment 2

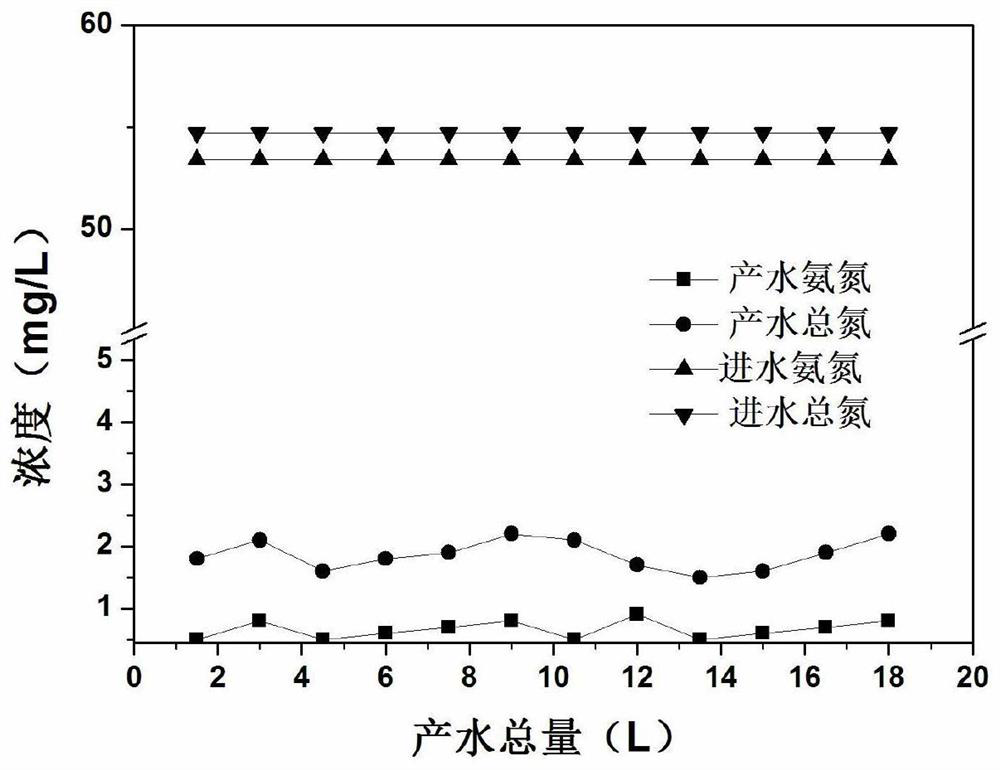

[0053] The actual water samples were retrieved from a municipal sewage treatment plant in Beijing, and the concentrations of ammonia nitrogen, total nitrogen, chloride ions, calcium ions and magnesium ions, and pH values of the water samples were determined.

[0054] Take 500mL water sample in a 1L transparent beaker, put a visible light micro-nano reactor membrane with a diameter of 8cm prepared in Example 1 into the water sample, and observe that the visible light micro-nano reactor membrane is in a suspended state in the water.

[0055] The beaker was placed on the open and flat ground outdoors, and was irradiated by sunlight for two hours. The beaker was taken back, and the water sample was analyzed again. The results are shown in Table 1 below.

[0056] Table 1 embodiment 1 every index of water sample

[0057]

[0058] It can be seen from Table 1 that the visible light micro-nano reactor membrane has a high selective removal effect on ammonia nitrogen, and the concen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com