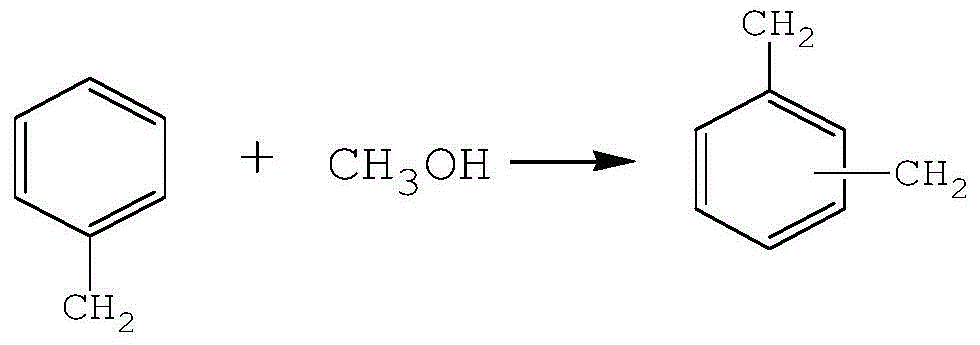

A reaction process for converting oxygenates to aromatics using moving bed technology

A moving bed reactor and compound technology, which is applied in the field of reaction technology, can solve the problems of low yield of total aromatics, strong reaction heat transfer and other problems, and achieve the effect of high activity and increased yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

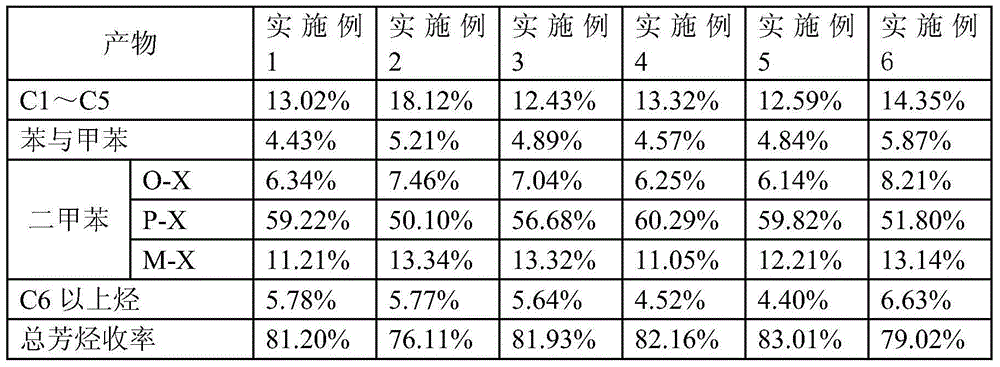

Embodiment 1

[0050] The raw material is methanol, the diluent is water (the total content of Na and K ions in the water is less than 60ppb), and the mass ratio of methanol to water is 1:5. The returned hydrocarbon, methanol and diluent are mixed and preheated to 300°C. Methanol in the imported gas The partial pressure is 0.05MPa, the catalyst is ZSM-5 molecular sieve modified by Ga and P, the content of Ga is 2wt%, the content of P is 5wt%, the average particle size of the catalyst particles is 1.5-3mm; the reaction temperature is 450℃, and the imported The pressure is 0.3MPa, and the space velocity is 0.1h -1 . The speed of the catalyst flowing through the moving bed reactor is set so that its residence time in the reactor is 20h. When the conversion rate of methanol is lower than 99%, the catalyst is sent to the regeneration zone for regeneration. The amount of coke deposited on the catalyst after regeneration is less than 0.5%. The product distribution of the catalyst in stable operat...

Embodiment 2

[0052] The raw material is methanol, the diluent is water (the total content of Na and K ions in the water is less than 60ppb), and the mass ratio of methanol to water is 10:1. The returned hydrocarbon, methanol and diluent are mixed and preheated to 500°C. Methanol in the imported gas Partial pressure is 0.1MPa, ZSM-5 molecular sieve modified by Zn and P is used as catalyst, Zn content is 6wt%, P content is 9wt%, average particle size of catalyst particles is 2-3mm; reaction temperature is 600℃, imported The pressure is 3MPa, and the space velocity is 1.5h -1 . The speed of the catalyst flowing through the moving bed reactor is set so that its residence time in the reactor is 300h. When the conversion rate of methanol is lower than 99%, the catalyst is sent to the regeneration zone for regeneration. The amount of coke deposited on the catalyst after regeneration is less than 0.5%. The product distribution of the catalyst in stable operation under this process is shown in Ta...

Embodiment 3

[0054] The raw material is methanol, the diluent is water (the total content of Na and K ions in the water is less than 60ppb), and the mass ratio of methanol to water is 1:10. The returned hydrocarbon, methanol and diluent are mixed and preheated to 380°C. Methanol in the imported gas The partial pressure is 0.01MPa, the catalyst is ZSM-5 molecular sieve modified by Ag and P, the content of Ag is 1wt%, the content of P is 3wt%, the average particle size of the catalyst particles is 1.5-3mm; the reaction temperature is 450℃, and the imported The pressure is 0.05MPa, and the space velocity is 1.0h -1 . The speed of the catalyst flowing through the moving bed reactor is set so that its residence time in the reactor is 100h. When the conversion rate of methanol is lower than 99%, the catalyst is sent to the regeneration zone for regeneration. The amount of coke deposited on the catalyst after regeneration is less than 0.5%. The product distribution of the catalyst in stable ope...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com