Method and system for recycling petrochemical wastewater

A technology of petrochemical wastewater and quicklime, applied in chemical instruments and methods, water pollutants, multi-stage water treatment, etc., can solve the problem of using petrochemical wastewater without a membraneless electrodeionization system, affecting resin regeneration efficiency, and poor resin conductivity to avoid hydroxide precipitation, ensure the quality of effluent water, and prevent resin pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

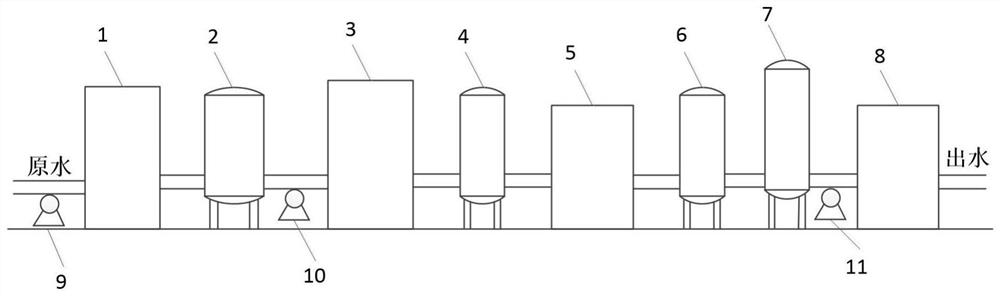

[0036] The copper and nickel-containing wastewater produced by a C9 petroleum resin enterprise is treated by this method and system, including the following steps:

[0037] (1) The raw water enters the regulating tank device, and the regulating tank is used to adjust the water quality and quantity;

[0038] (2) The effluent from the regulating tank enters the degreasing tank through the lifting pump, adds compressed air and degreasing agent, and after being fully mixed and reacted by the agitator, the oily substances are carried up by the microbubbles and stay for 25 minutes to remove the oily substances;

[0039](3) The effluent from the oil removal tank enters the neutralization coagulation sedimentation tank, and at the same time puts in quicklime and NaOH to adjust the pH to 8.5-9, and adds flocculants PAC 10-18mg / L, PAM 0.4-0.8mg / L, and the effluent enters after precipitation The primary filter, after filtering out solid matter, the filtered water enters the intermediate ...

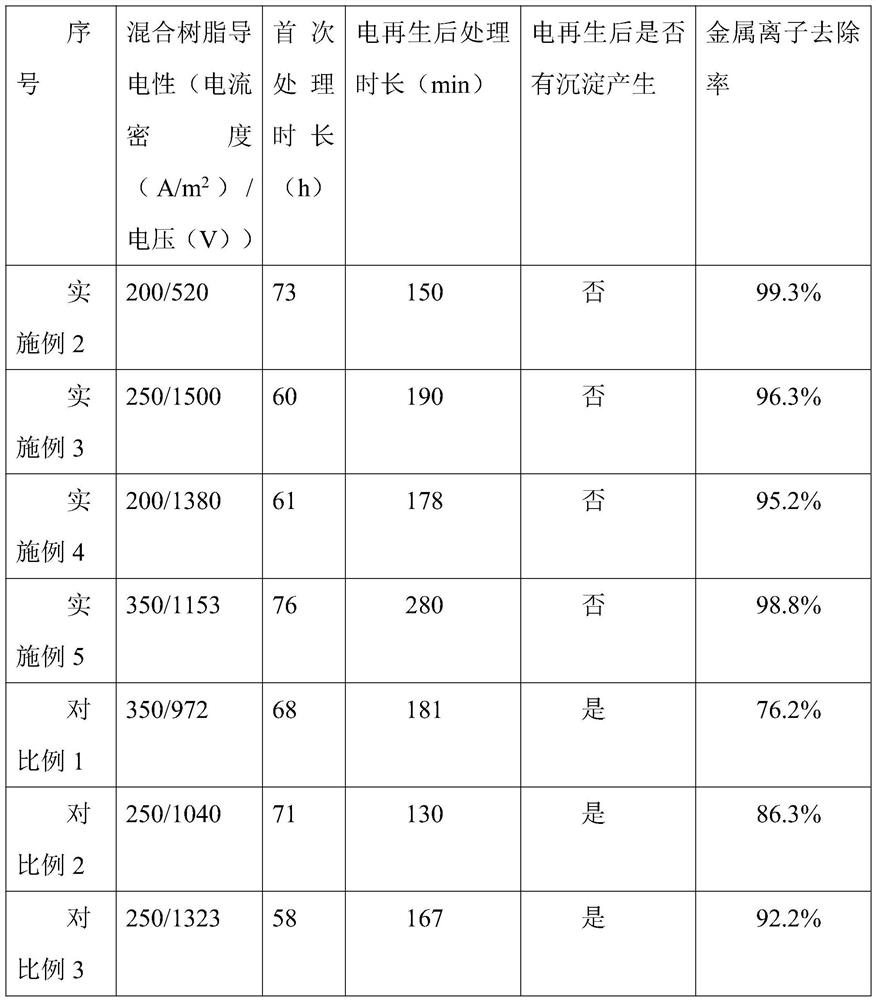

Embodiment 2

[0044] The copper and nickel-containing wastewater produced by a C9 petroleum resin enterprise is treated by this method and system, including the following steps:

[0045] (1) The raw water enters the regulating tank device, and the regulating tank is used to adjust the water quality and quantity;

[0046] (2) The effluent from the adjustment pool enters the degreasing tank through the lifting pump, and then adds compressed air and degreaser. After fully mixed and reacted by the agitator, the oily substances are carried up by the micro-bubbles and stay for 25 minutes to remove the oily substances;

[0047] (3) The effluent from the oil removal tank enters the neutralization coagulation sedimentation tank, at the same time, quicklime and NaOH are put in to adjust the pH to 8.5, and flocculants PAC 10mg / L and PAM 0.4mg / L are added. After precipitation, the effluent enters the primary filter and is filtered After removing the solid matter, filter the water into the intermediate ...

Embodiment 3

[0052] The copper and nickel-containing wastewater produced by a C9 petroleum resin enterprise is treated by this method and system, including the following steps:

[0053] (1) The raw water enters the regulating tank device, and the regulating tank is used to adjust the water quality and quantity;

[0054] (2) The effluent from the adjustment pool enters the degreasing tank through the lifting pump, and then adds compressed air and degreaser. After fully mixed and reacted by the agitator, the oily substances are carried up by the micro-bubbles and stay for 25 minutes to remove the oily substances;

[0055] (3) The effluent from the oil removal tank enters the neutralization coagulation sedimentation tank, at the same time put in quicklime and NaOH to adjust the pH to 8.6, add flocculant PAC 15mg / L, PAM 0.6mg / L, after precipitation, the effluent enters the primary filter, After removing the solid matter, filter the water into the intermediate pool;

[0056] (4) The lifting pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com