A method for producing light aromatics and clean fuel oil by hydrocracking in a moving bed

A light aromatics, hydrocracking technology, applied in chemical instruments and methods, treatment of hydrocarbon oil, through aromatics hydrorefining, etc. problems, to achieve the effect of reducing excessive hydrogenation, reducing chemical hydrogen consumption, and improving BTX yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

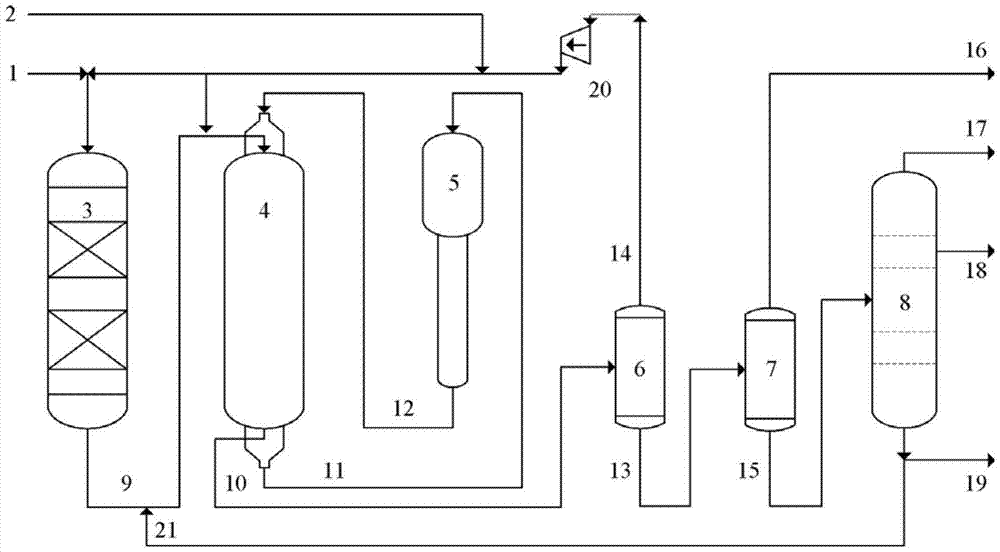

Method used

Image

Examples

Embodiment 1

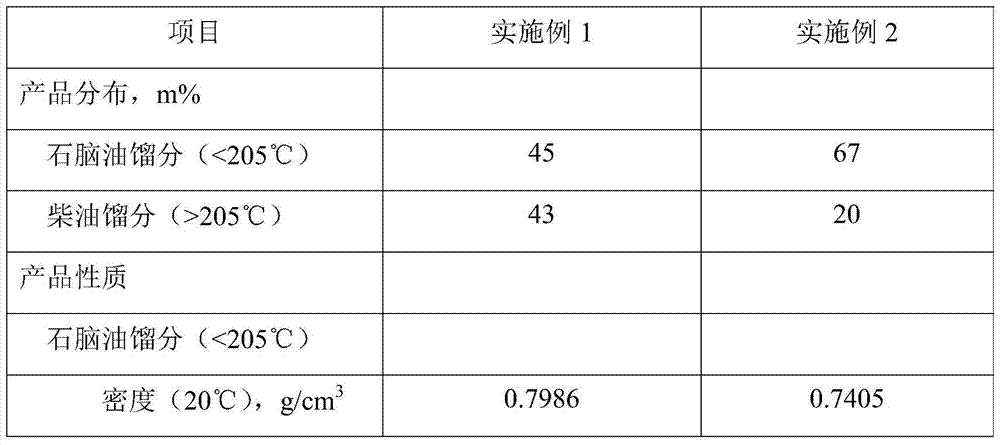

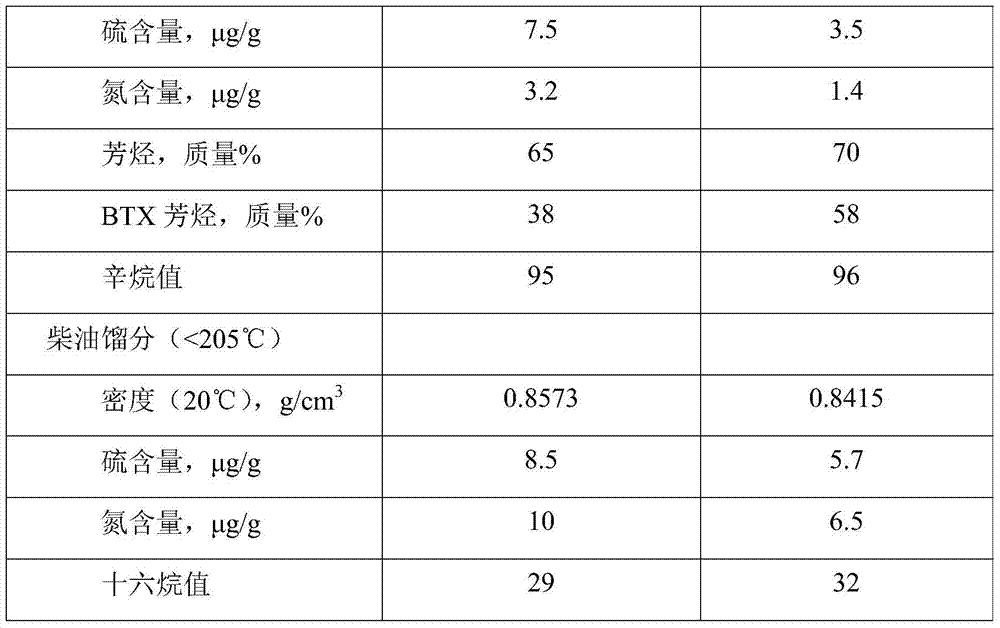

[0037] According to the method of the present invention, catalytic cracking diesel oil is processed to produce light aromatics and clean fuel oil through hydrocracking, and the fixed-bed hydrogenation reactor and the moving-bed hydrocracking reactor are filled with FDS-1 catalyst and hydrocracking catalyst I respectively. The reaction conditions and reaction results are shown in Table 2 and Table 3.

Embodiment 2

[0039] Process catalytic cracking diesel oil according to the method of the present invention, and produce light aromatics and clean fuel oil through hydrocracking, and the fixed bed hydrogenation reactor and the moving bed hydrocracking reactor are filled with FDS-1 catalyst and hydrocracking catalyst II respectively. The reaction conditions and reaction results are shown in Table 2 and Table 3.

[0040] Table 3 Reaction results

[0041]

[0042]

[0043] As can be seen from the results in Table 3, FCC diesel oil is treated according to the method of the present invention, and the sulfur and nitrogen contents in the high-octane clean gasoline blending component are all less than 10 μg / g, and the process can effectively reduce the excessive hydrogenation of light aromatics. In the obtained naphtha fraction, the content of aromatics is greater than 65% by mass, so that the octane number reaches more than 95; the content of sulfur and nitrogen in the obtained clean diesel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com