Catalytic diesel hydroconversion process

A technology of hydrogenation conversion and catalytic diesel oil, which is applied in the fields of hydrotreatment process, petroleum industry, molecular sieve catalyst, etc., which can solve the problem of strong saturation ability of gasoline components, unfavorable hydrogenation conversion to produce high-octane gasoline, and reduce gasoline components Problems such as hydrogenation saturation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

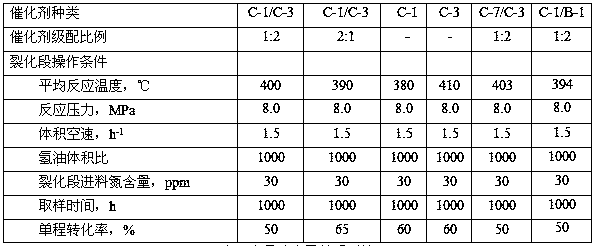

Embodiment 1

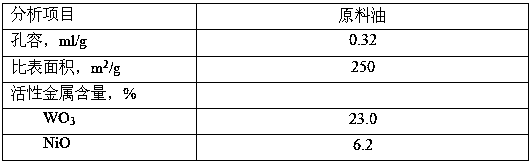

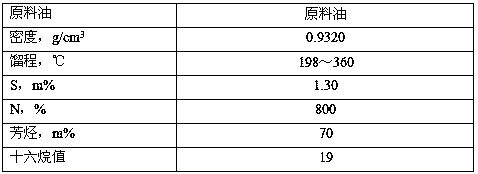

[0038] (1) Mix 150g of industrially produced modified Y molecular sieve with 50g of industrially produced macroporous alumina, add 4g / 100ml of dilute nitric acid, mix and roll in a mixer until it can be extruded, and extrude on an extruder to obtain the example 1 carrier;

[0039] (2) Configure Mo-Ni impregnation solution, MoO 3 1. Basic nickel carbonate is added to distilled water to prepare a partial Mo-Ni impregnation solution, and the MoO is adjusted in the mixed solution by the oxide of the metal salt. 3 26g / 100ml, NiO 8g / 100ml;

[0040] (3) Take the carrier in step 1 and impregnate it in the Mo-Ni active metal impregnation solution, and the impregnated sample is dried and calcined to obtain the catalyst C1.

Embodiment 2

[0042] (1) Take 200g of industrially produced macroporous alumina and place it in a closed container filled with butadiene atmosphere, control the pressure of 0.3MPa and fully contact it for 20 minutes, and then heat it at 180°C for 70 hours in an air atmosphere;

[0043] (2) Take 80g of alumina obtained in step (1), 50g of industrially modified Y molecular sieve, MoO 3 Mix 15g with 20g of cobalt nitrate, add 4g / 100ml of dilute nitric acid, mix and roll in a mixer until it can be extruded, and then extrude into strips;

[0044] (3) Step (2) After the sample was dried at 120°C for 4 hours in an air atmosphere, it was transferred to a nitrogen atmosphere and calcined at 500°C for 3 hours to obtain catalyst C2.

Embodiment 3

[0046] (1) Soak 200g of industrially produced macroporous alumina in heptene for 4 hours, then heat at 160°C for 120 hours in an air atmosphere;

[0047] (2) Mix 100g of alumina obtained in step (1) with 60g of industrially modified Y molecular sieve, add 4g / 100ml of dilute nitric acid in a mixer, mix, roll, extrude and form, then dry at 120°C for 4 hours to obtain the carrier of Example 3;

[0048] (3) Configure Mo-Co impregnation solution, MoO 3 , Basic cobalt carbonate is added to distilled water to prepare a partial Mo-Co impregnation solution, and the MoO is adjusted in the mixed solution by the oxide of the metal salt. 3 30g / 100ml, CoO 10g / 100ml;

[0049](4) Take the Mo-Co impregnation solution obtained in step (3), impregnate the catalyst carrier obtained in step (2) for 2 hours according to the liquid-solid ratio of 3:1, and then dry at 150°C for 2 hours in the air atmosphere, then transfer to CO 2 Catalyst C3 was obtained by calcining at 400° C. for 4 h in an air at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| dry point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com