Method for treating fluorine-containing reuse water

A treatment method and technology for water reuse, applied in multi-stage water treatment, water/sewage treatment, light water/sewage treatment, etc., can solve problems such as the inability to meet ultrapure water requirements, reduce fluorine content, and improve recycling. The effect of high efficiency and removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

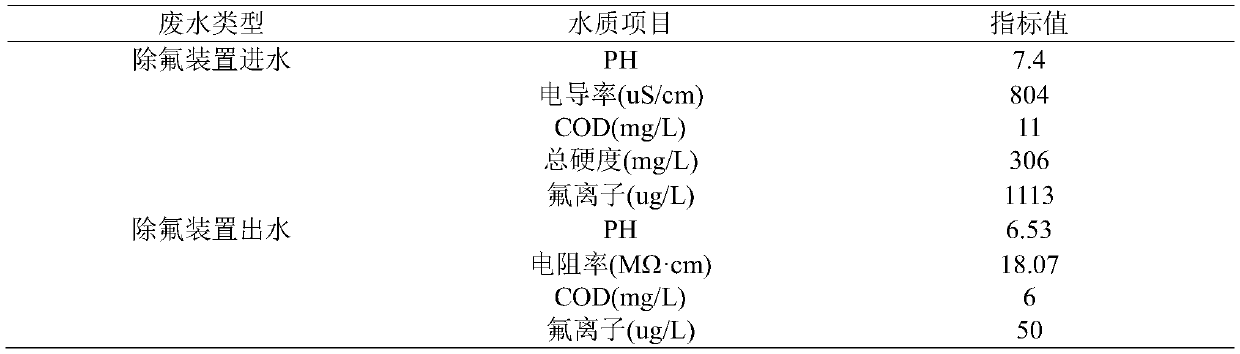

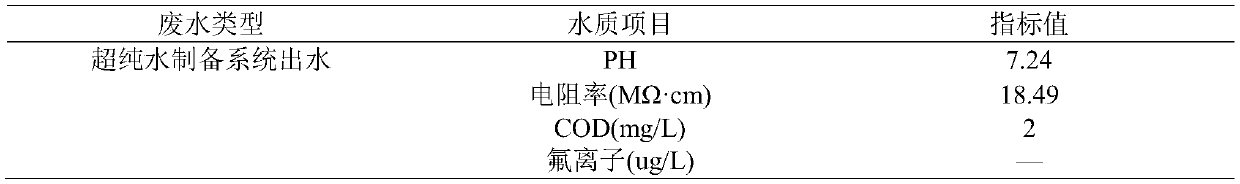

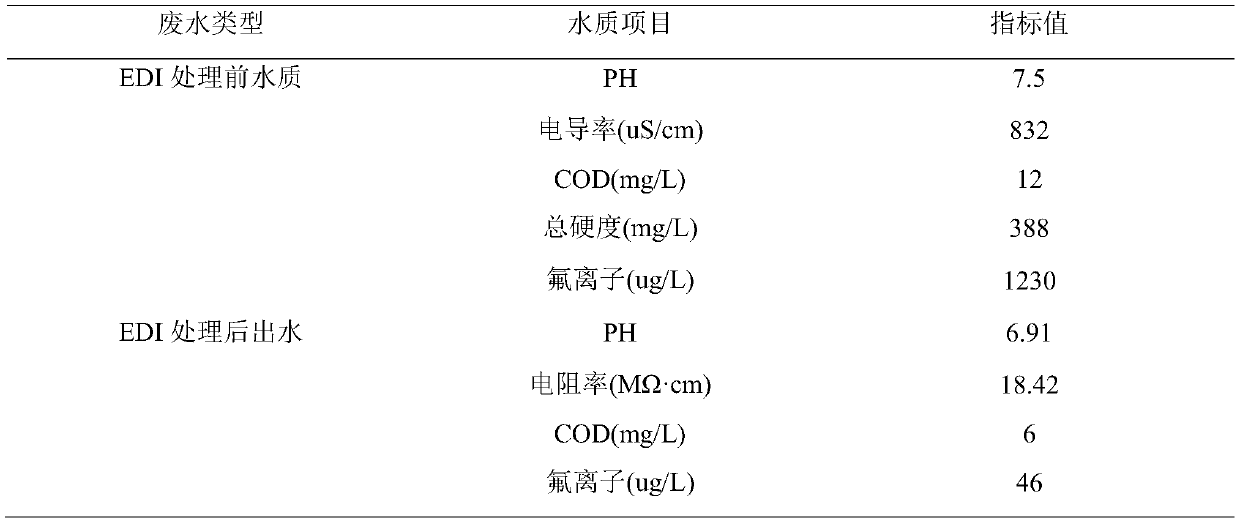

Examples

Embodiment 1

[0040] This embodiment takes fluorine-containing wastewater from the electronics industry, taking 2L of fluorine-containing wastewater from a microelectronics manufacturing plant, the raw water PH value is 2.84, the COD concentration is 86mg / L, and the fluoride ion concentration is 364mg / L as the object (the present invention uses direct ion selection The fluoride ion concentration in the water was measured by the sex electrode method, and the detection limit was 15.1 μg / L). The wastewater was treated by the treatment method of the present invention. The specific steps are as follows:

[0041] (1) Adjust the pH value of wastewater to 8-9, and introduce excess calcium hydroxide and calcium chloride solution into it to cause a chemical precipitation reaction to generate calcium fluoride.

[0042] (2) Flocculation and sedimentation. Step (1) Introduce coagulant PAC into the wastewater after chemical precipitation reaction to make small sediments generate larger particles, then adjust t...

Embodiment 2

[0058] This embodiment takes fluorine-containing wastewater from the electronics industry, taking 2L of fluorine-containing wastewater from a microelectronics manufacturing plant, the raw water PH value is 2.84, the COD concentration is 86mg / L, and the fluoride ion concentration is 364mg / L as the object (the present invention uses direct ion selection The fluoride ion concentration in the water was measured by the sex electrode method, and the detection limit was 15.1 μg / L). The wastewater was treated by the treatment method of the present invention. The specific steps are as follows:

[0059] (1) Adjust the pH value of wastewater to 8-9, and introduce excess calcium hydroxide and calcium chloride solution into it to cause a chemical precipitation reaction to generate calcium fluoride; based on the mass concentration of fluorine in the water, the hydroxide The dosage of calcium is The dosage of calcium chloride is

[0060] (2) Flocculation and sedimentation. Step (1) Introduce co...

Embodiment 3

[0075] This embodiment takes fluorine-containing wastewater from the electronics industry, taking 2L of fluorine-containing wastewater from a microelectronics manufacturing plant, the raw water PH value is 2.84, the COD concentration is 86mg / L, and the fluoride ion concentration is 364mg / L as the object (the present invention uses direct ion selection The fluoride ion concentration in the water was measured by the sex electrode method, and the detection limit was 15.1 μg / L). The wastewater was treated by the treatment method of the present invention. The specific steps are as follows:

[0076] (1) Adjust the pH value of wastewater to 8-9, and introduce excess calcium hydroxide and calcium chloride solution into it to cause a chemical precipitation reaction to generate calcium fluoride; based on the mass concentration of fluorine in the water, the hydroxide The dosage of calcium is The dosage of calcium chloride is

[0077] (2) Flocculation and sedimentation. Step (1) Introduce co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com