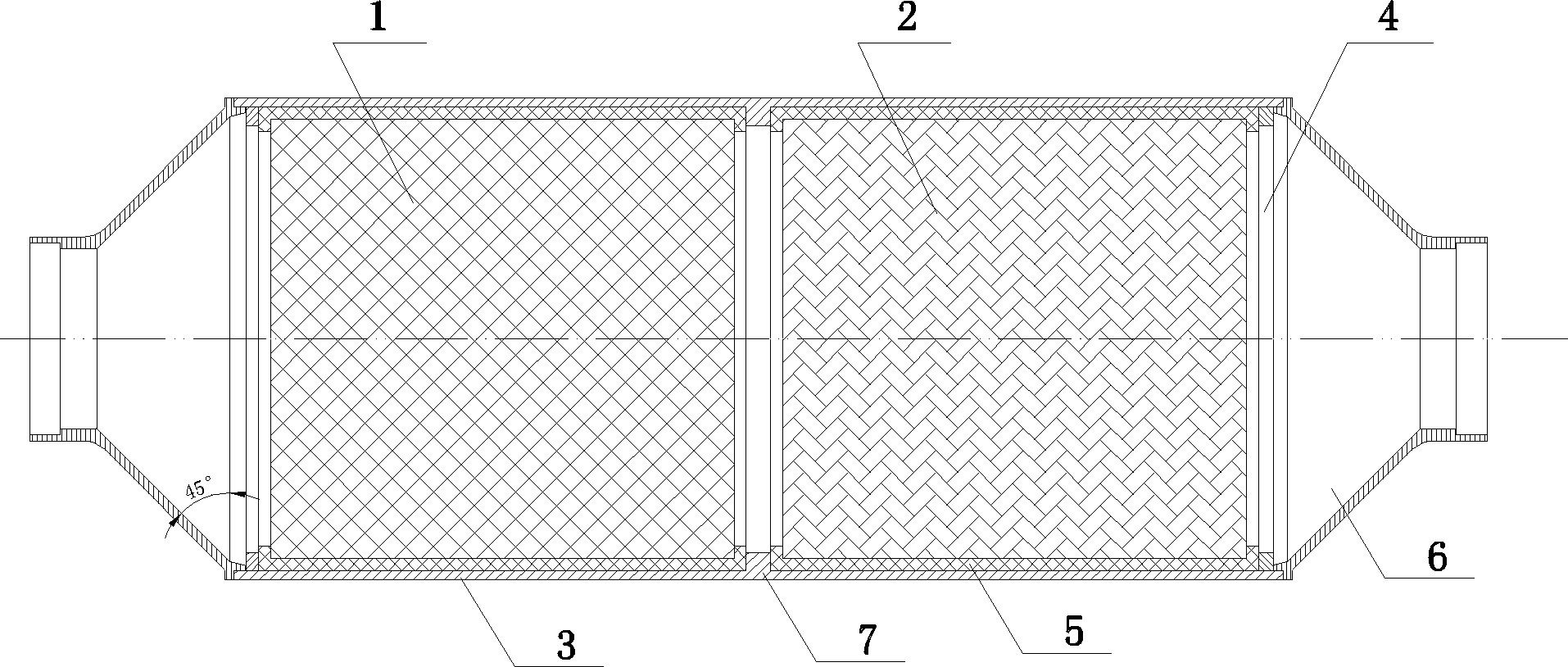

Catalyst for purifying tail gas of diesel automobiles, preparation method and purification device thereof

An exhaust gas purification, diesel vehicle technology, applied in physical/chemical process catalysts, chemical instruments and methods, air quality improvement, etc., can solve the problems of limited PM elimination, easy to be poisoned by sulfur, and needs to be further improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

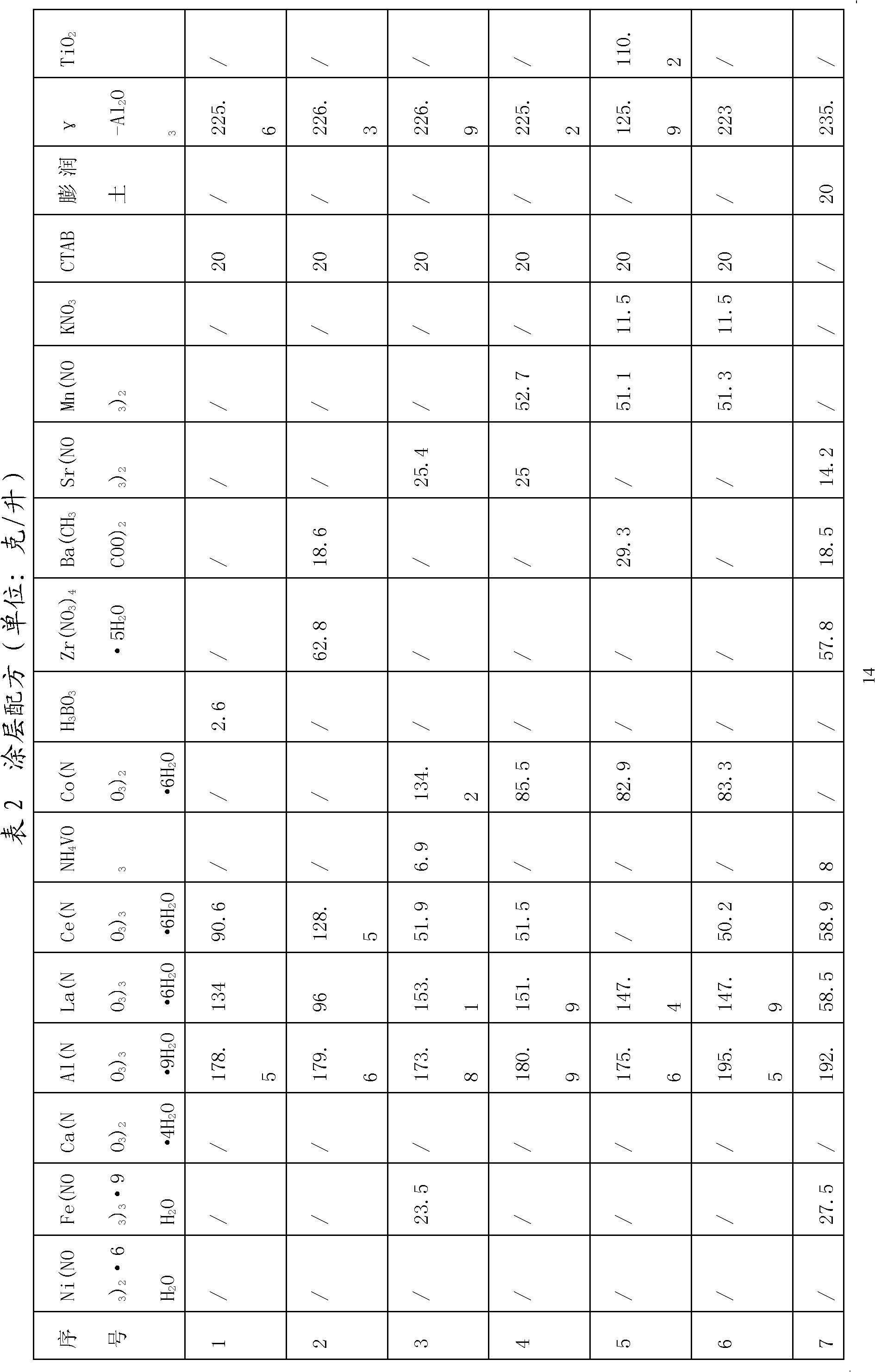

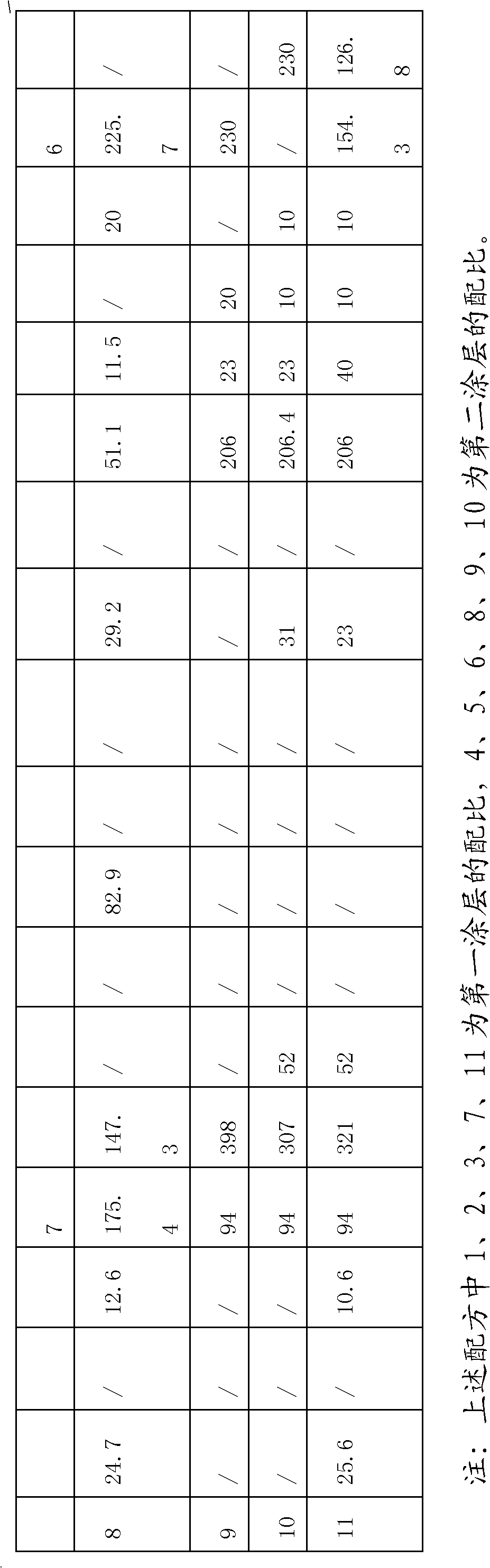

[0073] (2) Preparation of coating

[0074] 1) First coat

[0075] 1. take by weighing the proportioning corresponding nitrate (except Ba salt) of the first coating by the proportioning of table 2, heat and dissolve with a small amount of deionized water, must mix the nitrate solution;

[0076] ② Take the proportioning in Table 2 and weigh the Ba(CH 3 COO) 2 , add deionized water to dissolve, and obtain a solution containing Ba ions;

[0077] ③Weigh the ratio of Table 2 and weigh the γ-Al of the first coating ratio 2 o 3 powder, add the mixed nitrate solution described in step ①, and stir for 90-110min to obtain a mixed solution;

[0078] ④ Diffusely inject the Ba ion-containing solution obtained in step ② into the mixed solution obtained in step ③, and stir while adding to obtain the immersion solution;

[0079] ⑤ ball mill the immersion solution obtained in step ④ for 1 hour at a speed of 250r / min to obtain the first coating immersion solution;

[0080] 2) Second coat ...

Embodiment 1

[0093] Take one cordierite and one SiC wall flow carrier with a size of φ144mm×152mm, soak in deionized water for 30 minutes, dry at 80°C for 4 hours, and bake at 350°C for 30 minutes before use.

[0094] ① DOC preparation: weigh La(NO 3 ) 3 .6H 2 O: 243g, Ce(NO 3 ) 3 .6H 2 O: 235.5g, Zr(NO 3 ) 4 ·5H 2 O: 231.2g, Sr(NO 3 ) 2 : 56.7g, Fe(NO 3 ) 3 9H 2 O: 108.6g, NH 4 VO 3 : 32g, Al(NO 3 ) 3 9H 2 O: 770.6g, placed in a 5000ml beaker and heated to melt, then add 74.1g of Ba(CH 3 COO) 2 Saturated solution and 942.2g γ-Al 2 o 3 Nano powder, 80g inorganic thixotropic agent, the volume of the deployment solution is 4000ml, electric stirring for 100min., 250rpm ball milling for 1 hour to obtain the DOC coating immersion solution. Then immerse the treated cordierite carrier in the solution for 30min, and after taking it out, 0.3MPaN 2 Blow air, dry at 80°C for 4 hours, bake at 550°C for 1 hour, calculate the weight of the carrier to be used when it increases by mo...

Embodiment example 2

[0100] What is different from embodiment 1 is to change DOC and CDPF composition, all the other process parameters are constant:

[0101] DOC coating composition is: La(NO 3 ) 3 .6H 2 O: 612g, Ce(NO 3 ) 3 .6H 2 O: 207.6g, Co(NO 3 ) 4 ·6H 2 O: 536.9g, Sr(NO 3 ) 2 : 101.5g, Fe(NO 3 ) 3 9H 2 O: 93.8g, NH 4 VO 3 : 27.7g, Al(NO 3 ) 3 9H 2 O: 695.4g, γ-Al 2 o 3 Nano powder 907.7g, inorganic thixotropic agent 80g

[0102] The composition of DPF is: La(NO 3 ) 3 .6H 2 O: 1232g, KNO 3 : 82.8g, Ce(NO 3 ) 3 ·6H 2 O: 177.6g, Mn(NO 3 ) 2 : 204.4g, Co(NO 3 ) 2 ·6H 2 O: 331.8g, Al(NO 3 ) 3 9H 2 O: 736g, γ-Al 2 o 3 Nano powder 503.7g, TiO 2 Nano powder 400g.

[0103] The test results of purification rate are: HC75.8%, CO96.8%, PM92.8%, NO x 56.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com