A kind of regeneration method of alkylation waste sulfuric acid

A technology for alkylating waste sulfuric acid and waste sulfuric acid, which is applied in the direction of sulfur trioxide/sulfuric acid, etc., can solve the problems of increasing the energy consumption of sulfuric acid stripping, achieve the reduction of exhaust gas pollutant emissions, low energy consumption in operation, and reduce the intermediate storage process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

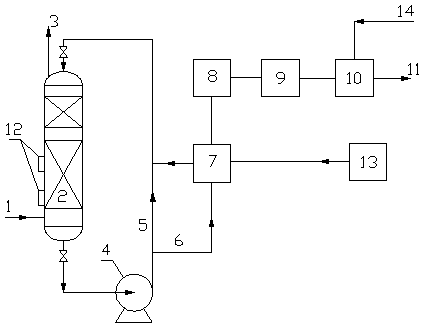

Embodiment 1

[0033] 90wt% of waste sulfuric acid is heat exchanged to 120°C, and mixed with circulating sulfuric acid liquid into reactor 2. The ratio of the first packed bed to the second packed bed in the reactor is 1:1, and the second packed bed The heat carrier of the layer is heated to about 600°C by microwave. The heat carrier of the first packed bed and the second packed bed is made of 10mm silica spherical particles, and the regenerated heat stream 1 of the reactor 2 uses the incineration flue gas of the sulfur incinerator. The waste sulfuric acid cokes and deposits carbon in the hot bed of reactor 2, and the treated sulfuric acid is discharged according to the ratio of 1:0.4, and is exchanged through the heat exchanger to filter tiny particles in the filter, and the filtered sulfuric acid and oleum are mixed at 98.5 % concentrated sulfuric acid is sent to the alkylation unit for use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com