A Rotary Fixed Bed Raw Gas Dust Removal System and Method

A technology of dust removal system and waste gas, applied in the field of coal chemical industry, can solve the problems of low dust removal efficiency, poor recoil regeneration effect, easy carbon formation of electrode wire, etc., and achieve the effects of improving dust removal efficiency, reducing heat loss and stable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

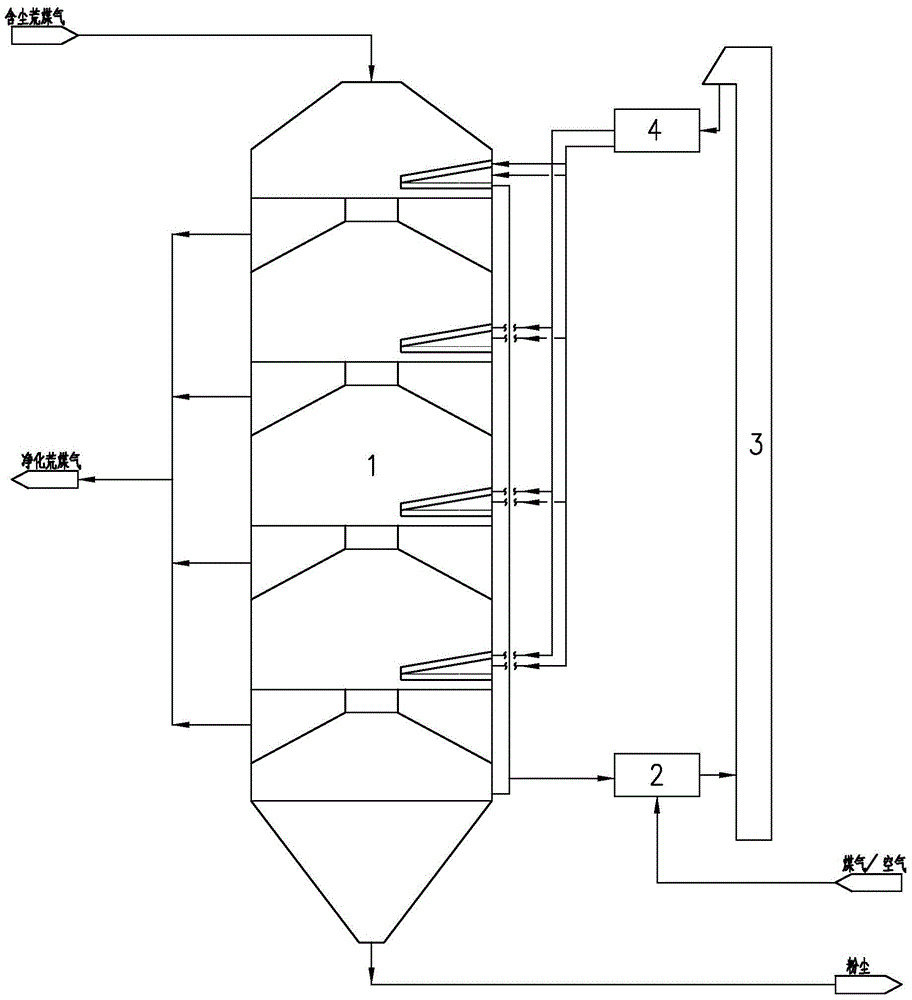

[0026] see figure 1 , The rotating fixed bed raw gas dedusting system of this embodiment is composed of a dust collector 1, a filter regeneration furnace 2, a high-temperature bucket elevator 3 and a high-temperature vibrating screen 4.

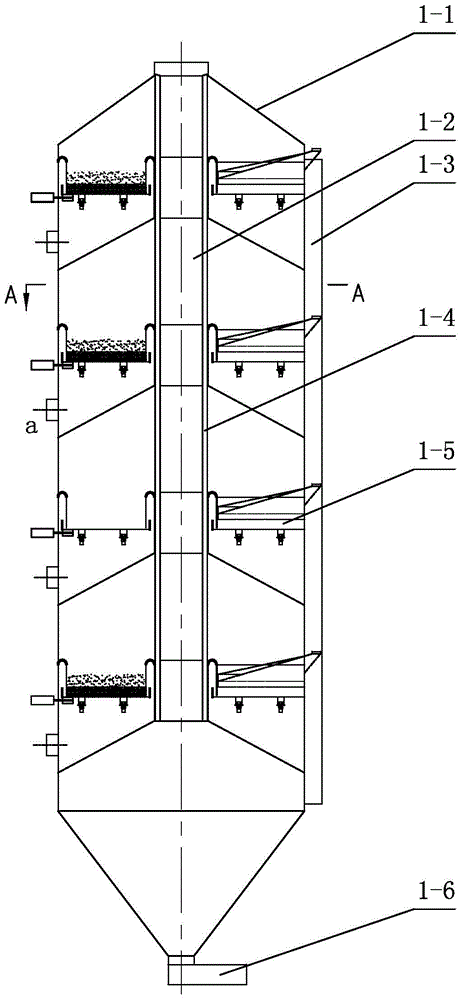

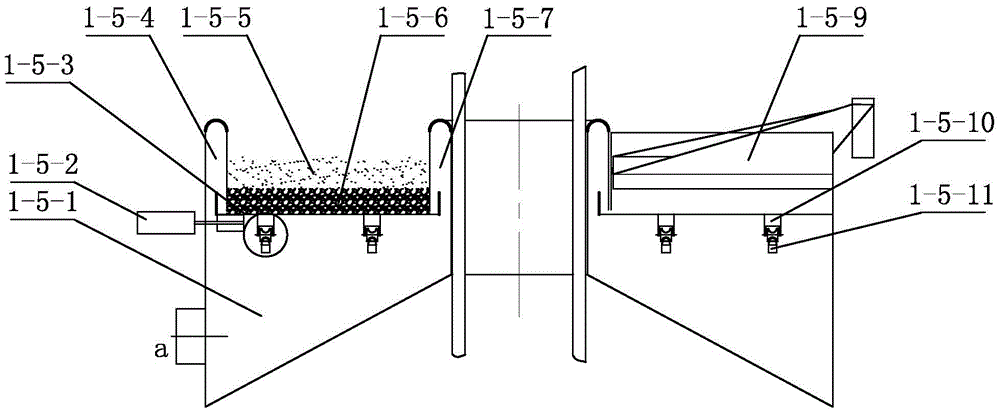

[0027] The dust collector 1 of this embodiment is composed of a tank body 1-1, a filter material collection bin 1-3 welded on the outer wall of the tank body 1-1, and an inner cylinder 1-2 installed in the inner cavity of the tank body 1-1, Screw discharger 1-6, support column 1-4, rotating bed 1-5, see figure 2 . Both the top and the bottom of the tank body 1-1 in this embodiment have a conical structure, which is convenient for air intake and discharge. An air inlet is processed at the center of the top of the tank body 1-1, and an inner cylinder 1-2 with a diameter of 1.5m is set on the air inlet, and is arranged on the left side wall of the tank body 1-1 from top to bottom There are 4 outlets a for purified gas, and 4 discharge ports ...

Embodiment 2

[0034] In the dust collector 1 of this embodiment, two purified gas outlets a are sequentially processed from top to bottom on the left side wall of the tank body 1-1, and two discharge ports are processed on the right side wall of the tank body 1-1. b, there is a filter material collection bin 1-3 on the outer cover of the discharge port b, and the surroundings of the filter material collection bin 1-3 are welded on the outer wall of the tank body 1-1, and at the bottom of the filter material collection bin 1-3 The outlet of the processed filter material is communicated with the filter material regeneration furnace 2 through a pipeline. An inner cylinder 1-2 with a diameter of 5m is installed in the center of the inner cavity of the tank 1-1 along the axial direction. The inner cylinder 1-2 is formed by stacking two short tubes, and its top extends to the tank 1 -1 The top is sleeved on the air inlet. In order to strengthen the structural strength of the inner cylinder 1-2, f...

Embodiment 3

[0039] The dust remover 1 of this embodiment has 6 outlets a for purified gas sequentially processed on the left side wall of the tank body 1-1 from top to bottom, and 6 discharge ports are processed on the right side wall of the tank body 1-1 b, there is a filter material collection bin 1-3 on the outer cover of the discharge port b, and the surroundings of the filter material collection bin 1-3 are welded on the outer wall of the tank body 1-1, and at the bottom of the filter material collection bin 1-3 There is a filter outlet for processing. An inner cylinder 1-2 with a diameter of 3m is installed in the center of the inner cavity of the tank 1-1 along the axial direction. The inner cylinder 1-2 is composed of 6 short tubes superimposed, and its top extends to the tank 1 -1 top, sleeved on the air inlet, in order to strengthen the structural strength of the inner cylinder 1-2, four support columns 1-4 distributed at intervals are installed along the axial direction on the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com