Crude benzene hydrogenation method

A technology of crude benzene and hydrogenation catalyst, which is applied in the direction of hydrogenation treatment process, chemical instruments and methods, hydrocarbons, etc., and can solve the problems of ineffective utilization of heavy components, increased investment and energy consumption, and reduced added value of crude benzene, etc. problem, achieve the effects of accelerating the diffusion rate and contact area, inhibiting coke formation, and strong solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

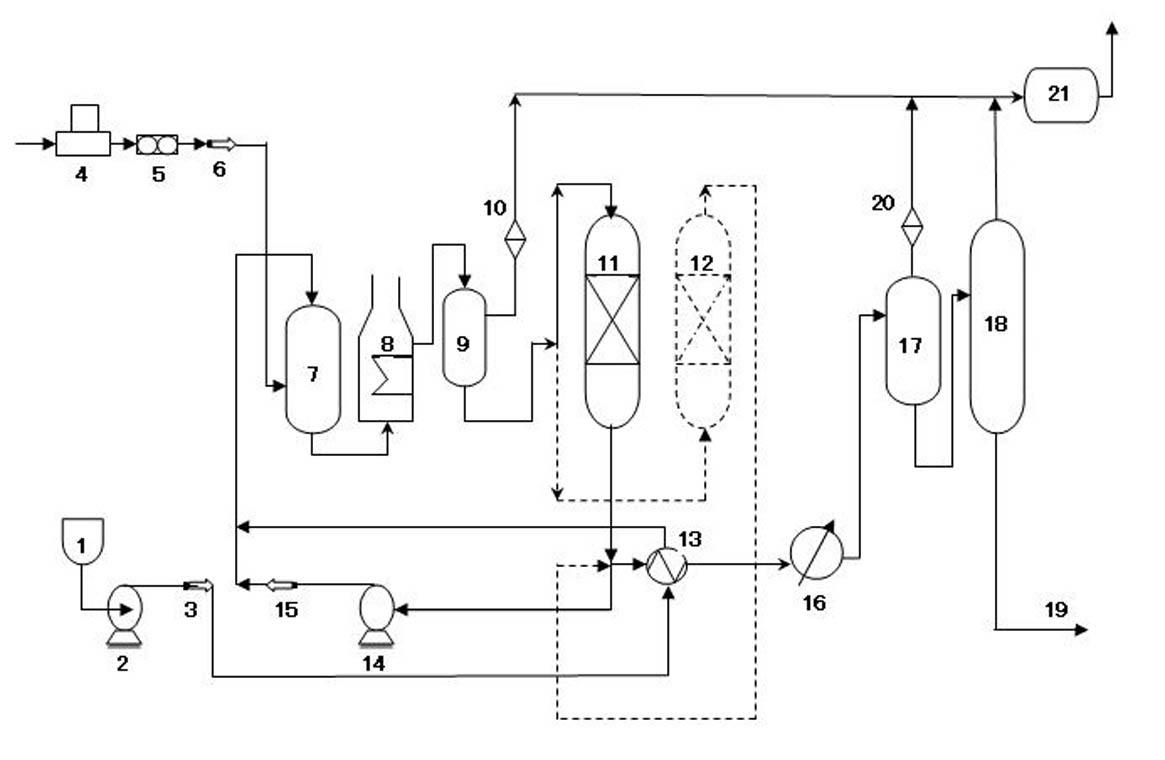

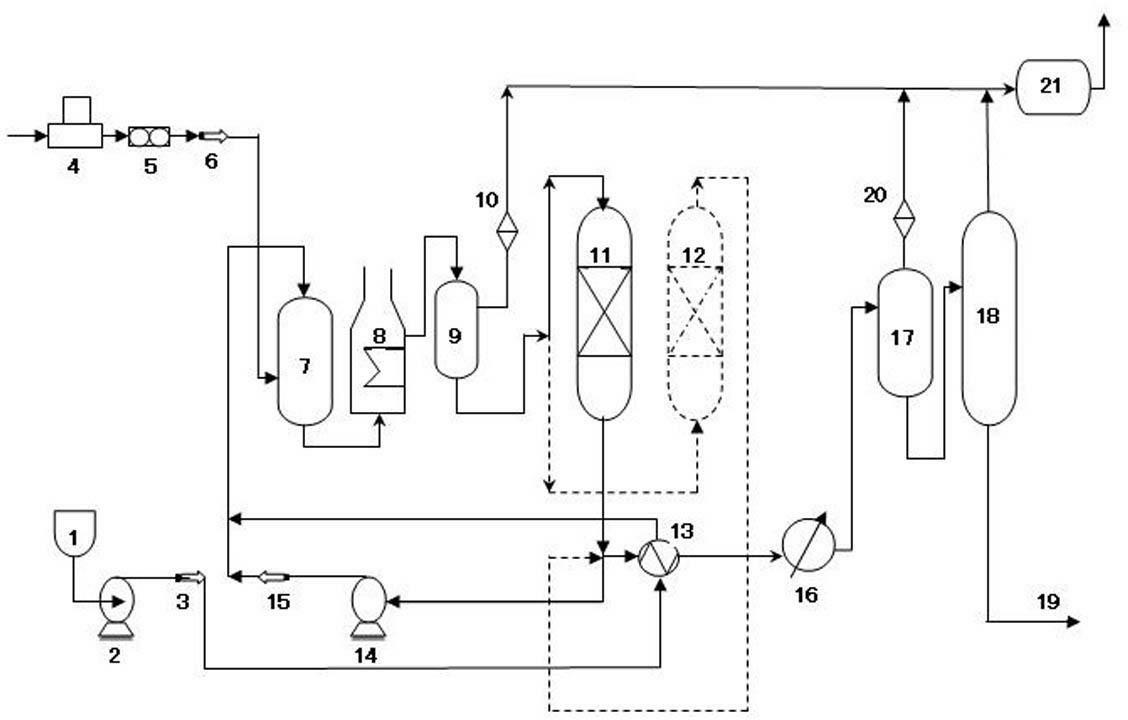

Method used

Image

Examples

Embodiment 1

[0036] A raw material of crude benzene, whose properties are shown in Table 2. The reaction conditions of full liquid phase hydrogenation: reaction temperature 320°C, reaction pressure 7.0MPa, reflux circulation volume of hydrogenation product 80%, reaction liquid hourly space velocity 1.0h -1 . See Table 3 for the pressure drop in the reactor during hydrogenation and the properties of the hydrogenation product.

[0037] Table 2

[0038] project value project value Density, Kg / m 3 881.7 Family Composition m% Total S, ppm 3006 Alkanes 1.67 Total N, ppm 2162 Naphthenic 1.66 Bromine value, gBr 2 / 100g 6.09 Alkenes 0.15 Aromatics 96.52

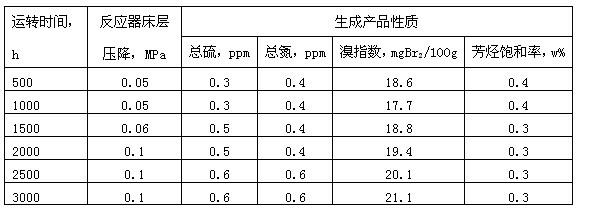

[0039] table 3

[0040]

[0041] It can be seen from Table 3 that the hydrogenation product obtained by the present invention effectively removes sulfur and nitrogen impurities in the raw material, the loss rate of light aromatics is 0.3-0.4%, the total sulfur is 0.3-0....

Embodiment 2

[0043] A raw material of crude benzene, whose properties are shown in Table 4, the reaction conditions of full liquid phase hydrogenation: reaction temperature 331°C, reaction pressure 5.5MPa, reflux circulation volume of hydrogenation product 70%, reaction liquid hourly space velocity 2.0h -1 . See Table 5 for the pressure drop in the reactor during hydrogenation and the properties of the hydrogenation product.

[0044] Table 4

[0045] project value project value Density, Kg / m 3 882.1 Family Composition m% Total S, ppm 4525 Alkanes 2.12 Total N, ppm 2562 Naphthenic 1.98 Bromine value, gBr 2 / 100g 7.17 Alkenes 0.21 Aromatics 95.69

[0046] table 5

[0047]

[0048] It can be seen from Table 5 that the hydrogenation product obtained by the present invention effectively removes sulfur and nitrogen impurities in the raw material, the loss rate of light aromatics is 0.3-0.4%, the total sulfur is 04-0....

Embodiment 3

[0050] A raw material of crude benzene, whose properties are shown in Table 6. The reaction conditions of full liquid phase hydrogenation: reaction temperature 345°C, reaction pressure 4.0MPa, reflux circulation volume of hydrogenation product 60%, reaction liquid hourly space velocity 4.0h -1 . See Table 7 for the hydrogenation operation time reactor pressure drop and the properties of the hydrogenation product.

[0051] Table 6

[0052] project value project value Density, Kg / m 3 882.2 Family Composition m% Total S, ppm 5562 Alkanes 2.56 Total N, ppm 1963 Naphthenic 2.01 Bromine value, gBr 2 / 100g 5.85 Alkenes 0.24 Aromatics 95.19

[0053] Table 7

[0054]

[0055] It can be seen from Table 3 that the hydrogenation product obtained by the present invention effectively removes sulfur and nitrogen impurities in the raw material, the loss rate of light aromatics is 0.3-0.5%, the total sulfur is 0.5-0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com