Assembly type electric cable trench and construction method therefor

A cable trench and assembly technology, which is applied in the direction of cable installation, cable laying equipment, ground cable installation, etc., can solve the problems that the installation process cannot be effectively simplified, the L-shaped trench body is not convenient for transportation, and the cost of transportation and storage is high. Achieve the effects of light weight, shortened construction period, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

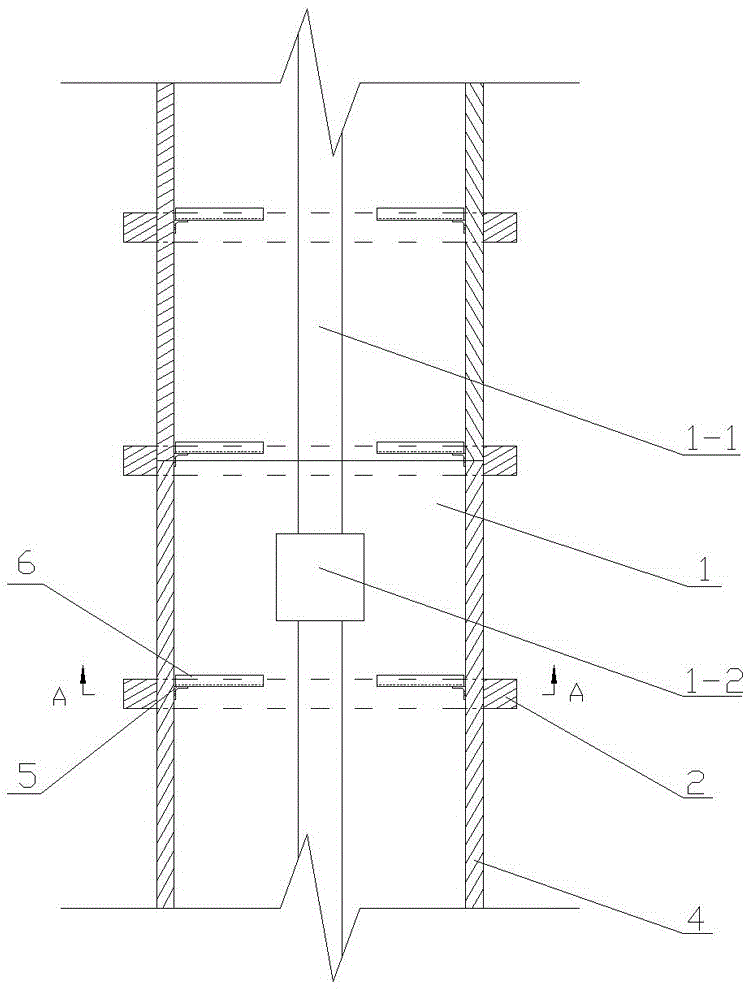

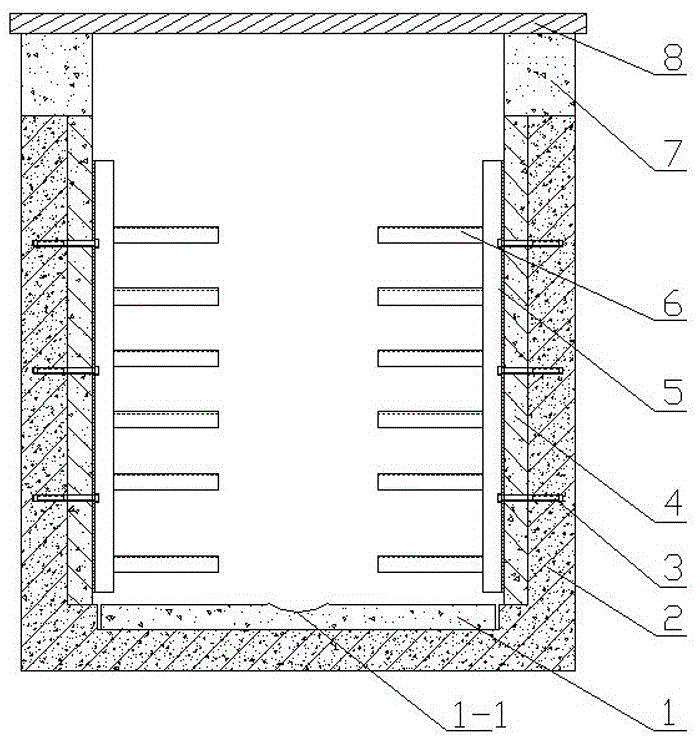

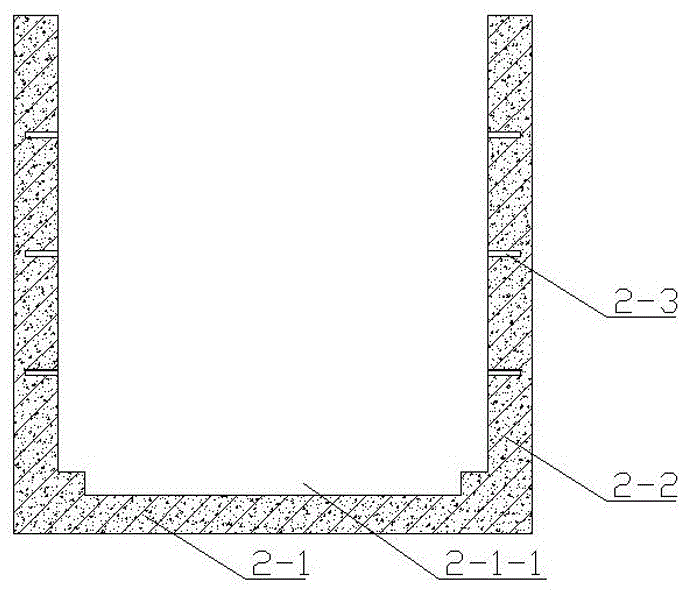

[0028] see Figure 1~Figure 3 , the cable groove of the present embodiment includes a U-shaped groove and a matching cover plate 8, and the U-shaped groove includes more than two U-shaped brackets 2 provided with assembly holes 2-3, which are connected with the U-shaped brackets in turn by means of connectors 3. The uprights on both sides of the bracket 2 are assembled with the side vertical plate 4 and the cable support 6, and the bottom plate 1 laid on the bottom of the U-shaped bracket 2. The side vertical plate 4 and the bottom plate 1 are between two or more U-shaped brackets 2. The space is assembled into a U-shaped groove with the U-shaped bracket 2 as a frame by means of the connecting piece 3 . The U-shaped brackets 2 are distributed in the length direction and interval of the cable trench, the length of the bottom plate 1 and the side vertical plate 4 is greater than the distance between the two U-shaped brackets 2, and the U-shaped brackets for the bottom plate 1 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com