Semiautomatic streamline type production system and method for high-strength threaded steel bar

An assembly line and production system technology, applied in the field of high-strength threaded steel bar production system, can solve problems such as low processing efficiency, high labor intensity, and difficult to guarantee product performance, and achieve the effect of improving production efficiency and reducing product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

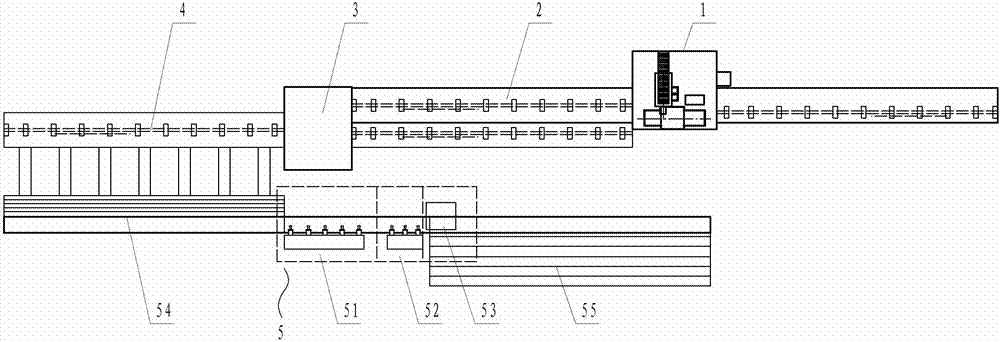

[0090] figure 1 What is disclosed is a semi-automatic assembly line production system for high-strength threaded steel bars. The system includes a centerless lathe 1, a thread rolling machine 3, and a heat treatment system 5. The centerless lathe 1 is a commonly used CNC centerless lathe with automatic feeding The CNC centerless lathe of the mechanism, the centerless lathe 1 and the thread rolling machine 3 are connected together by the automatic connection device 2, and the thread rolling machine 3 and the heat treatment equipment 5 are connected together by the thread rolling machine automatic feeding mechanism 4. The system forms a semi-closed U-shaped structure.

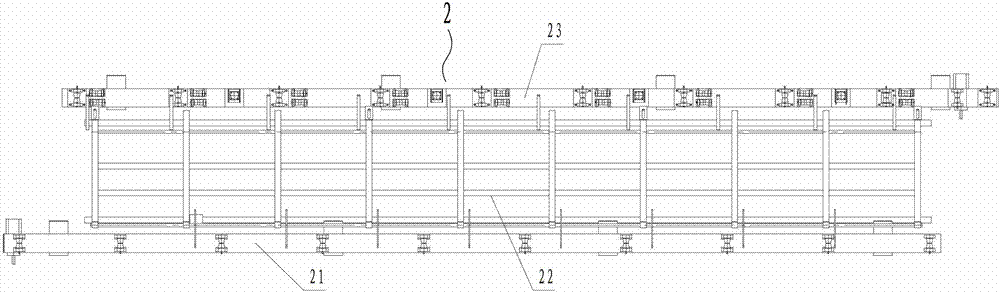

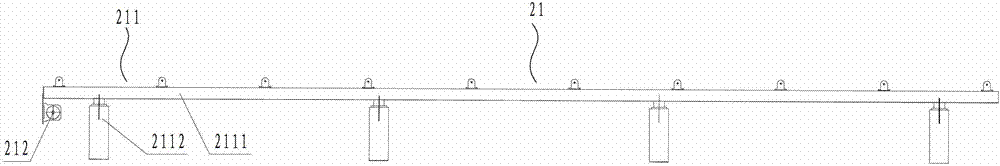

[0091] The automatic coupling device 2 is composed of a discharge rack 21, a transfer rack 22 and a feed rack 23 which are connected side by side in sequence (see figure 2 ), the discharging frame 21 is connected with the discharge port of the centerless lathe 1, and the feeding frame 23 is connected with the feedin...

Embodiment 2

[0096] A semi-automatic assembly line production method for high-strength threaded steel rods. The method is a method for processing high-strength threaded steel rods using the semi-automatic assembly line production system of high-strength threaded steel rods described in the first embodiment. The method includes the following steps (see Figure 14 ):

[0097] S1. Blanking: The round steel is blanked in sections according to a fixed length to obtain a steel bar blank;

[0098] S2. Outer circle of car: Use a centerless lathe to car out the outer circle of the steel bar blank to obtain the semi-finished steel bar;

[0099] S3. Thread rolling: rolling the semi-finished steel bar on the thread rolling machine to obtain the semi-finished threaded steel bar;

[0100] S4. Heat treatment: Use the intermediate frequency online heat treatment system to heat and blacken the semi-finished steel rods to obtain high-strength threaded steel rod products;

[0101] S5. Inspection and warehousing: inspe...

Embodiment 3

[0120] A semi-automatic assembly line production method of high-strength threaded steel bars, the basic steps of the method are the same as in Example 2, the difference is: the step S4. The specific parameters involved in the heat treatment are different, the step S4. The specific contents of heat treatment are as follows:

[0121] S4.1. Feeding:

[0122] The semi-finished threaded steel bar is transported to the intermediate frequency induction hardening equipment 51 through the transfer roller table and the horizontal movement platform 54 of the heat treatment system 5;

[0123] S4.2. Quenching heating:

[0124] The semi-finished threaded steel rod is subjected to 6-level induction quenching heating, the first 3 levels are preheating heating, and in the first M-level preheating heating, the temperature of the semi-finished threaded steel rod in the latter stage is controlled to be 20℃ higher than the temperature of the previous stage. The last three levels are heat preservation an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com