Welding gun device of soldering equipment

A welding equipment and welding torch technology, applied in the field of welding equipment, can solve problems such as insufficient bonding between the soldering iron tip and the welding product, defective products exceeding the standard, and scratches on the soldering iron tip, so as to improve product quality and yield rate, and reduce the risk of damage cost, the effect of ensuring quality requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

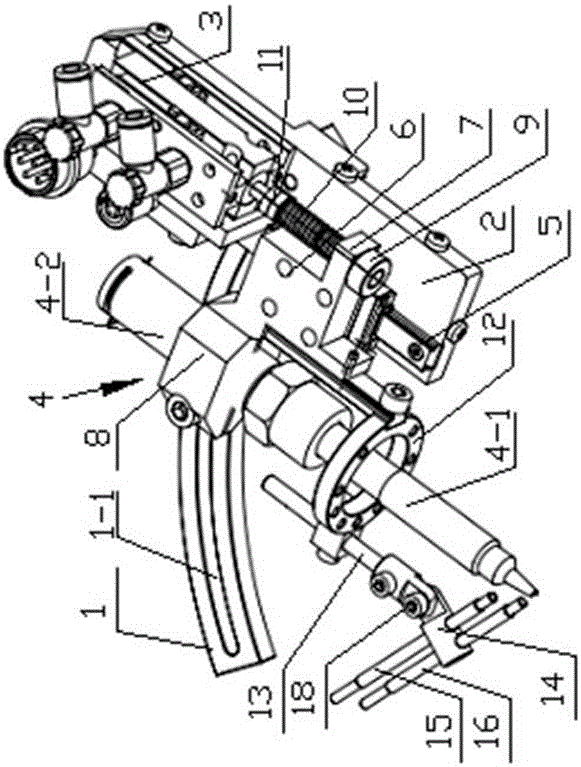

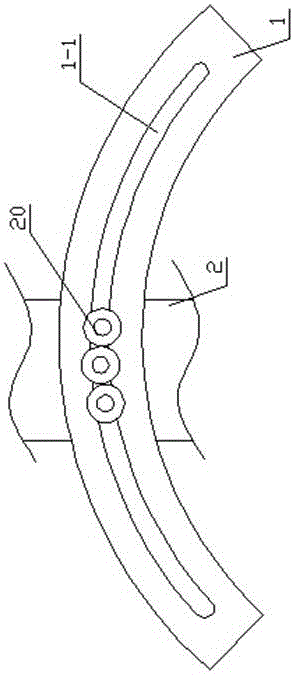

[0019] Such as figure 1 , 2 , 3, and 4, the present invention includes an arc-shaped fixing bracket 1, a welding torch base 2, a lifting cylinder 3 and a welding torch assembly 4, the arc-shaped fixing bracket 1 is fixed on the welding platform, and the arc-shaped fixing bracket 1 is provided with an arc-shaped groove 1-1, the position of the center of the arc-shaped groove 1-1 is the position of the welding point of the product, the first bolt 20 is arranged in the arc-shaped groove 1-1, the back of the welding torch base 2 and the first bolt 20 in the arc-shaped groove 1-1 A bolt 20 is threaded so that the welding torch base 2 can slide relative to the arc-shaped groove 1-1, and the first bolt 20 can also be tightened to fix the welding torch base 2 and the arc-shaped fixing bracket 1 as one.

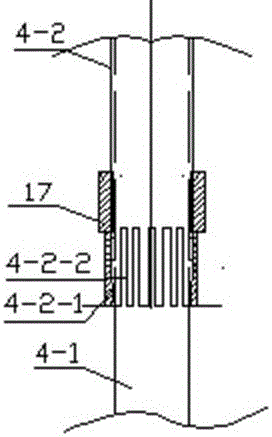

[0020] A vertical slide rail 5 is installed on the welding torch base 2, and a sliding seat 6 is slidably installed on the sliding rail 5. One side of the sliding seat 6 is integrall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com