Preparation method of heat dissipation layer of heat sink as well as heat sink

A heat dissipation layer and heat sink technology, which is applied in semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., can solve the problems of poor heat dissipation improvement effect of heat sinks, etc., to improve heat dissipation effect, avoid corrosion, and increase service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

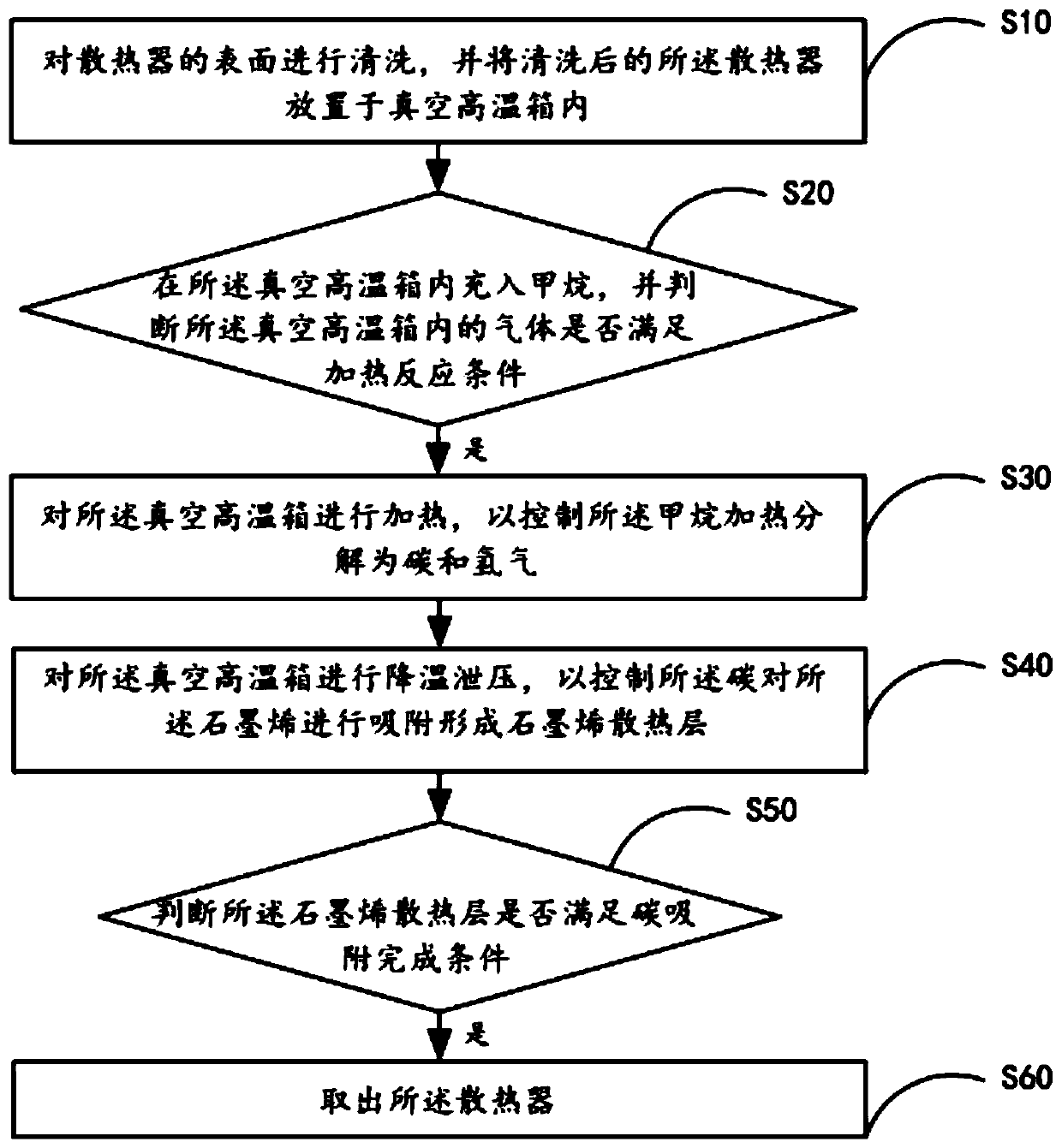

[0045] see figure 1 , is a flow chart of the method for preparing the heat dissipation layer of the radiator provided in the first embodiment of the present invention, including steps:

[0046] Step S10, cleaning the surface of the radiator, and placing the cleaned radiator in a vacuum high-temperature box;

[0047] Wherein, in this step, the cleaning operation of the surface of the radiator is performed by means of an automatic cleaner to improve cleaning efficiency, and the driving of the radiator in this step is automatically completed by a mechanical arm. There is a driver program, and after the mechanical arm runs the corresponding driver program, it can automatically complete the driving of the radiator, that is, place the cleaned radiator in the vacuum high-temperature box. Specifically, in this embodiment, the vacuum high-temperature The box is used for heat preservation effect on the preparation of the heat dissipation layer on the surface of the radiator, so as to i...

Embodiment 2

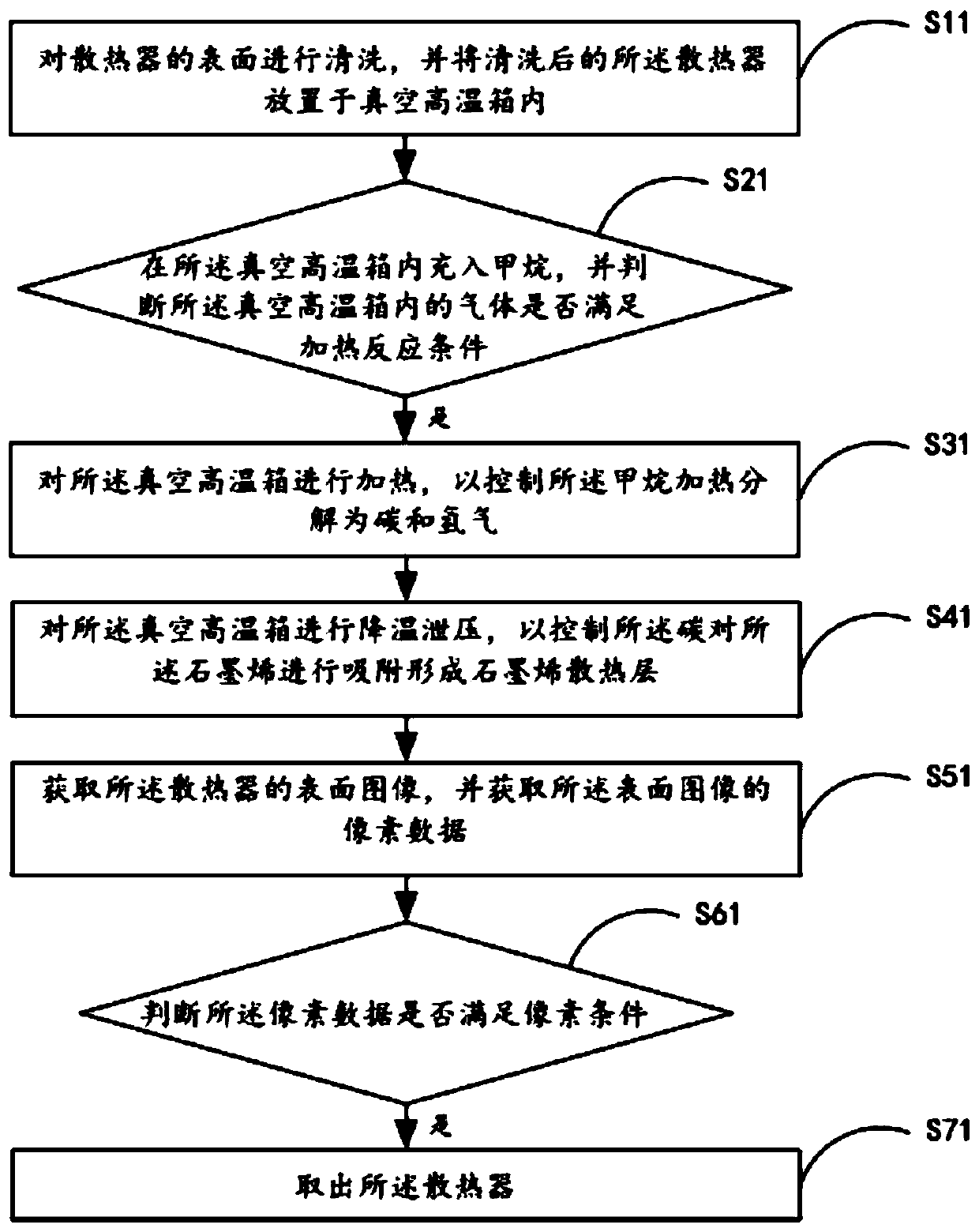

[0063] see figure 2 , is a flow chart of the method for preparing the heat dissipation layer of the radiator provided in the second embodiment of the present invention, including steps:

[0064] Step S11, cleaning the surface of the radiator, and placing the cleaned radiator in a vacuum high-temperature box;

[0065] Wherein, in this step, the cleaning operation of the surface of the radiator is performed by means of an automatic cleaner to improve cleaning efficiency, and the driving of the radiator in this step is automatically completed by a mechanical arm. There is a driver program, and after the mechanical arm runs the corresponding driver program, it can automatically complete the driving of the radiator, that is, place the cleaned radiator in the vacuum high-temperature box. Specifically, in this embodiment, the vacuum high-temperature The box is used for heat preservation effect on the preparation of the heat dissipation layer on the surface of the radiator, so as to...

Embodiment 3

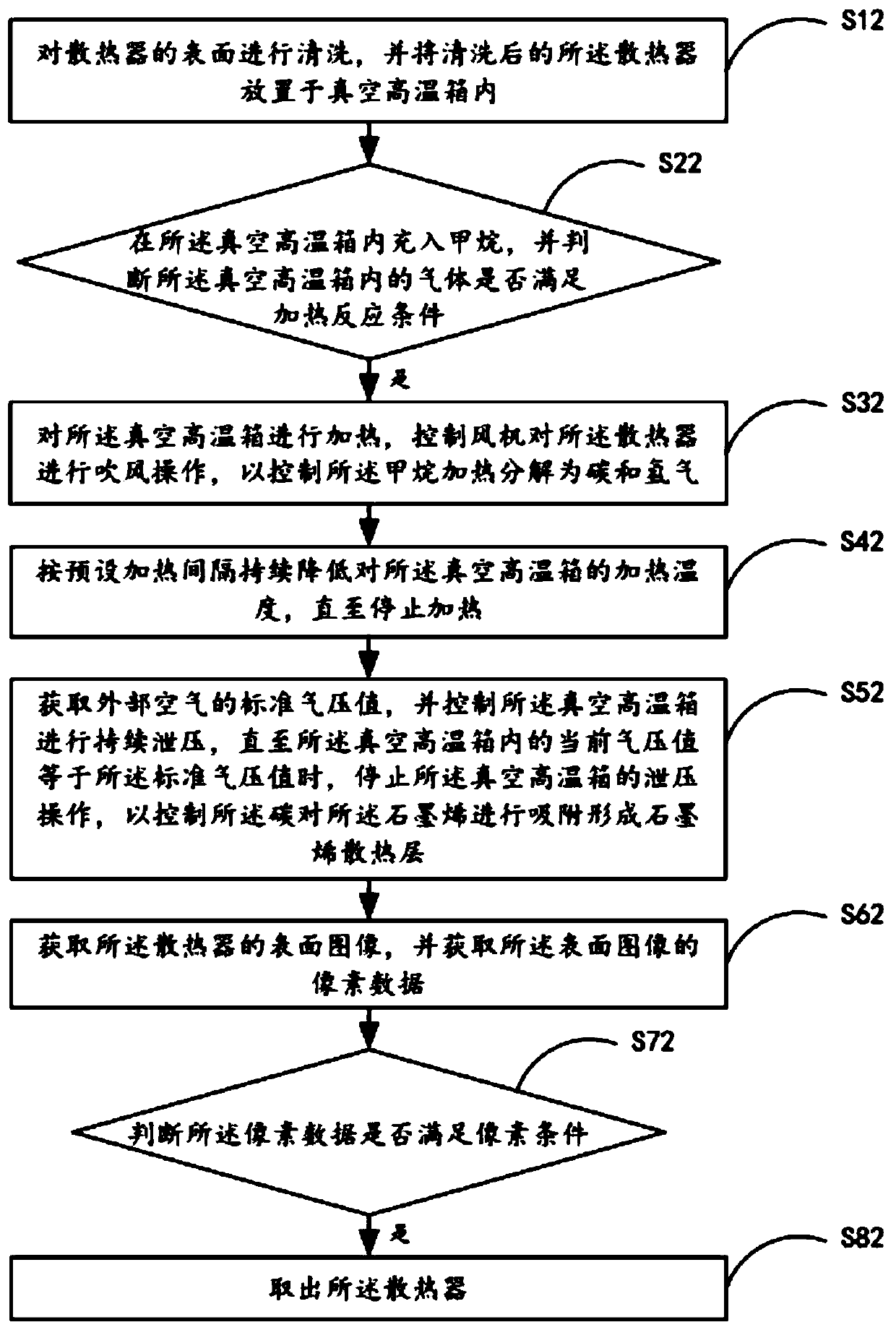

[0093] see image 3 , is a flow chart of the method for preparing a heat dissipation layer of a radiator provided in the third embodiment of the present invention, including steps:

[0094] Step S12, cleaning the surface of the radiator, and placing the cleaned radiator in a vacuum high-temperature box;

[0095] Wherein, in this step, the cleaning operation of the surface of the radiator is performed by means of an automatic cleaner to improve cleaning efficiency, and the driving of the radiator in this step is automatically completed by a mechanical arm. There is a driver program, and after the mechanical arm runs the corresponding driver program, it can automatically complete the driving of the radiator, that is, place the cleaned radiator in the vacuum high-temperature box. Specifically, in this embodiment, the vacuum high-temperature The box is used for heat preservation effect on the preparation of the heat dissipation layer on the surface of the radiator, so as to impro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com