Mass transfer reinforced bubbling fixed bed photocatalytic carbon dioxide reduction reactor and method

A bed photocatalytic carbon dioxide and reactor technology, applied in the field of solar photocatalytic reactions, can solve the problems of limited mass transfer, low local concentration, limited catalyst loading, etc., to achieve enhanced mass transfer, increased activity, and improved mass transfer performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

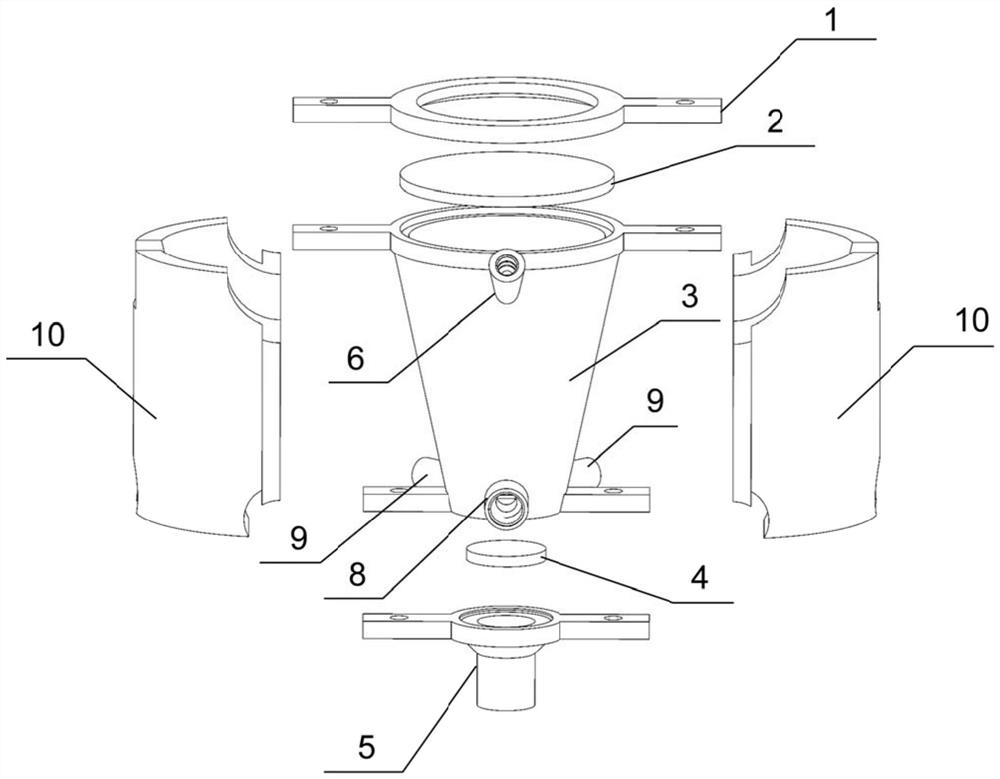

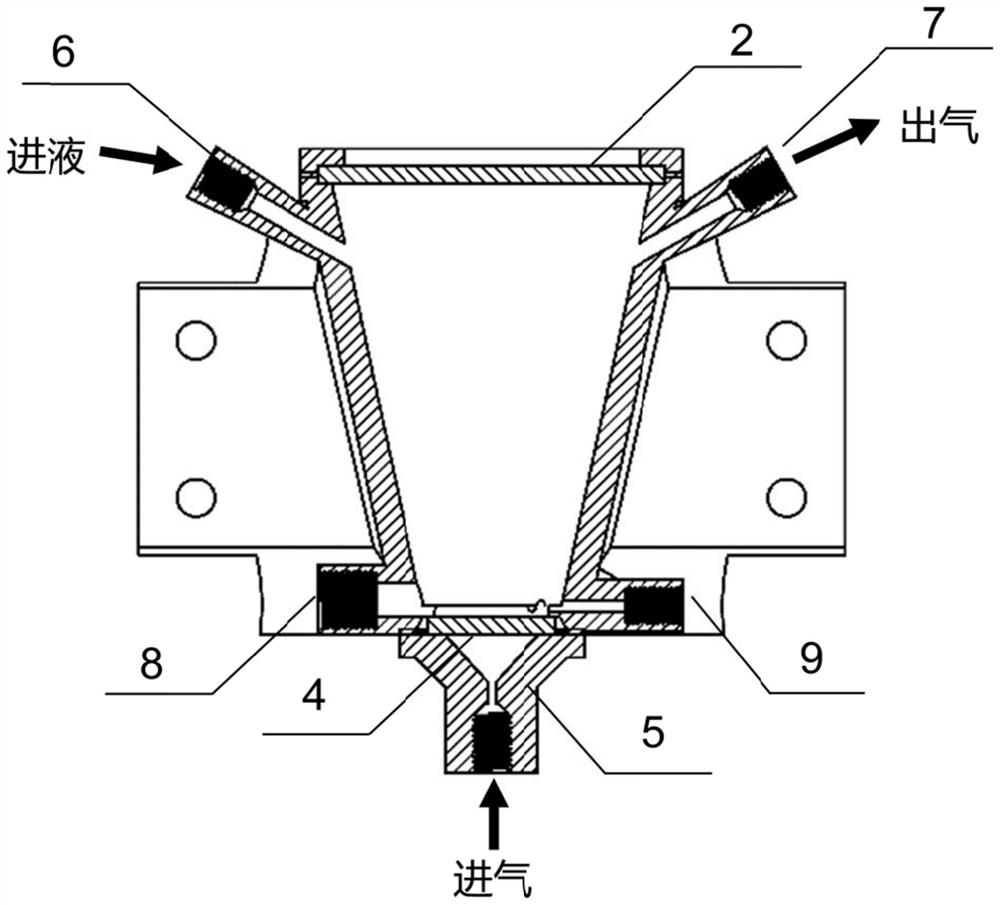

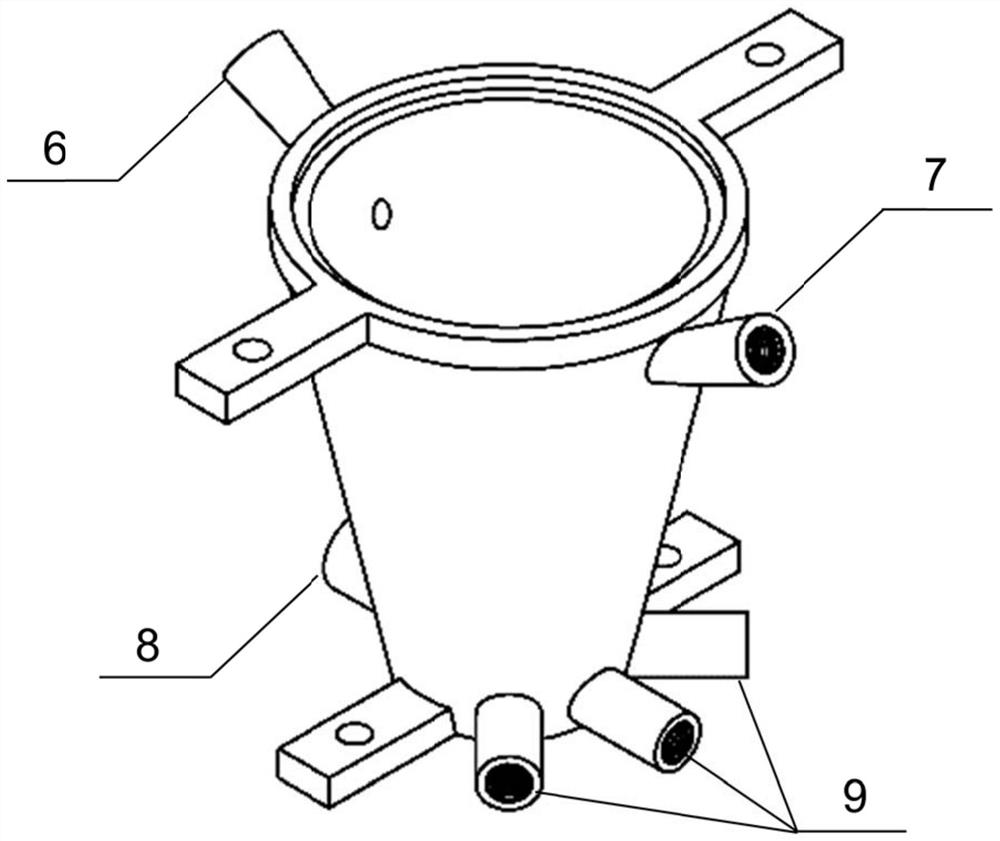

[0050] see Figure 1 to Figure 3 As shown, the present invention provides a bubbling fixed bed photocatalytic carbon dioxide reduction reactor with enhanced mass transfer, comprising a light window cover plate 1, a quartz light window 2, a reaction chamber 3, a bubbling bed 4, an air inlet base 5 and Heat exchange jacket 10.

[0051] The reaction cavity 3 is in the shape of a rounded truncated cone, and the interior is hollow to form a reaction space; the cross-section of the reaction space is an equilateral trapezoid. The quartz optical window 2 is placed between the optical window cover 1 and the upper surface of the reaction chamber 3, and the optical window cover 1, the quartz optical window 2 and the reaction chamber 3 are tightly sealed by bolts on both sides. The bubbling bed 4 is placed between the lower end of the reaction chamber 3 and the upper end of the air inlet base 5, and the reaction chamber 3, the bubbling bed 4 and the air inlet base 5 are connected by bolt...

Embodiment 2

[0056] In this example, the reaction device was used for CuInS at room temperature (25°C). 2-x Nanocatalyst photocatalytic CO 2 Reduction reaction: select microporous quartz sand core (average pore size is 200nm) as bubbling bed 4, and 50mg CuInS 2-x The powder photocatalyst was spin-coated and supported on the bubbling bed 4 of the microporous quartz sand core and placed in the reactor system. The in-situ monitoring hole is provided with an in-situ camera, and the sensor holes are respectively set as a temperature sensor, a pressure sensor, and a pH meter. When the reactor is running, the center of the sensor hole is 5 mm from the upper surface of the gas bubbling bed 4 .

[0057] The heat exchange jacket 10 selects the condensation mode, and the circulating heat exchange working medium is set to water at 25°C; The main body material of the heat exchange jacket 10 is stainless steel. The outer side of the air inlet hole of the air inlet base 5 is set as a threaded hole, t...

Embodiment 3

[0061] In this example, the reaction device was used for 80°C TiO 2 -C 3 N 4 Nanocatalyst photothermal catalysis of CO 2 Reduction reaction: copper foam (average pore size is about 50 μm) is used as the bubbling bed 4, and TiO is grown by in-situ hydrothermal growth. 2 -C 3 N 4 Nanoparticles are supported on the bubbling bed 4 of foamed copper, and the bubbling bed 4 is placed in this reactor system. The in-situ monitoring hole is provided with an in-situ camera, and the sensor holes are respectively set as a temperature sensor, a pH meter, and a pressure sensor. When the reactor is running, the distance between the center of the sensor hole and the upper surface of the bubble dispersion bed is 5 mm.

[0062] The heat exchange jacket 10 selects a heating mode, the heat exchange jacket 10 is connected to an external heating power source and the constant temperature is set to 80°C. The outer side of the air inlet hole of the air inlet base 5 is set as a threaded hole, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com