Sulfidizing agent supply method for use in catalyst wet sulfidizing process

A technology of vulcanizing agent and hydrogenation catalyst, applied in catalyst activation/preparation, chemical instruments and methods, chemical/physical process, etc., can solve the problems of slow decomposition rate of vulcanizing agent and insufficient vulcanization of catalyst

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

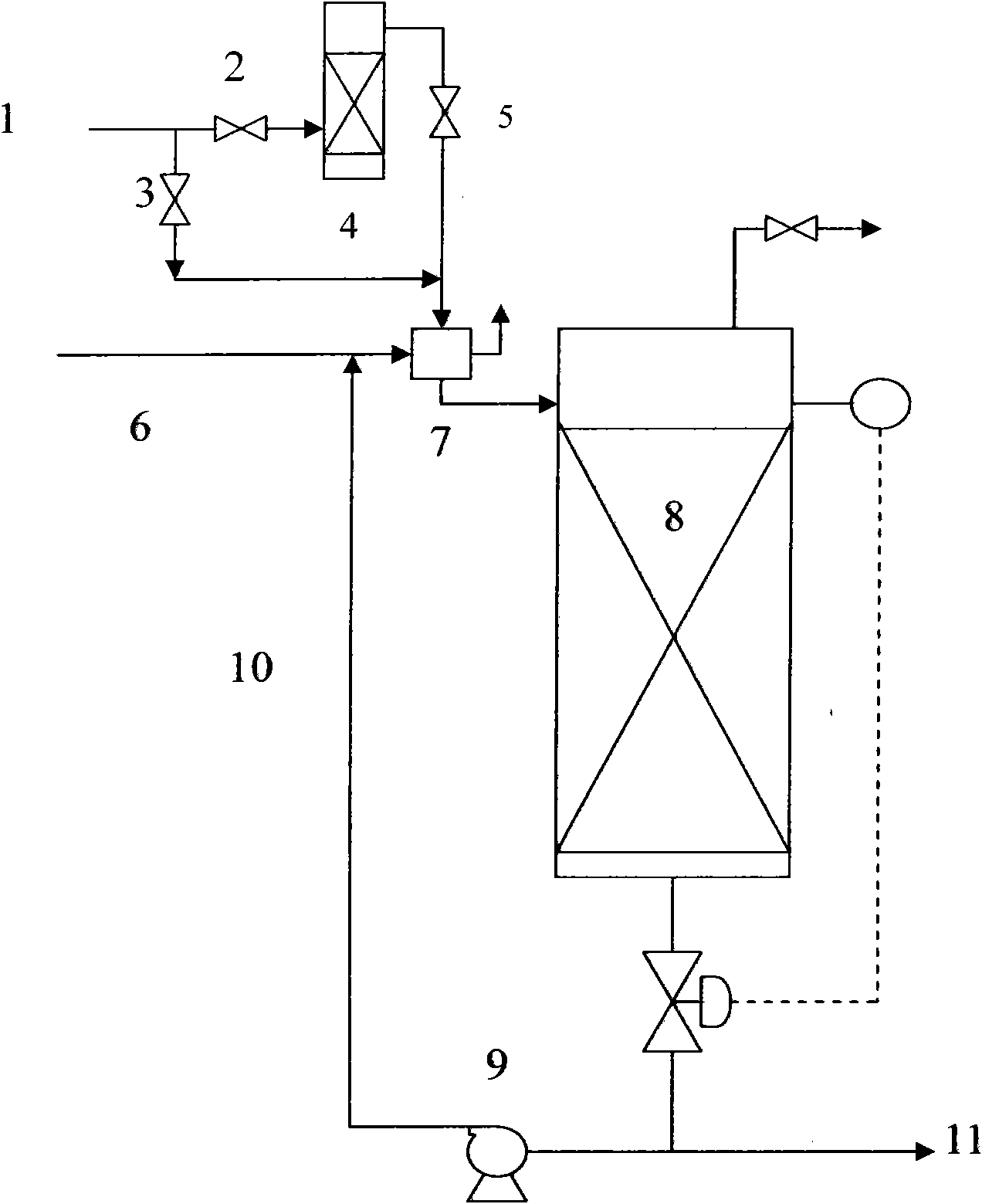

Method used

Image

Examples

Embodiment

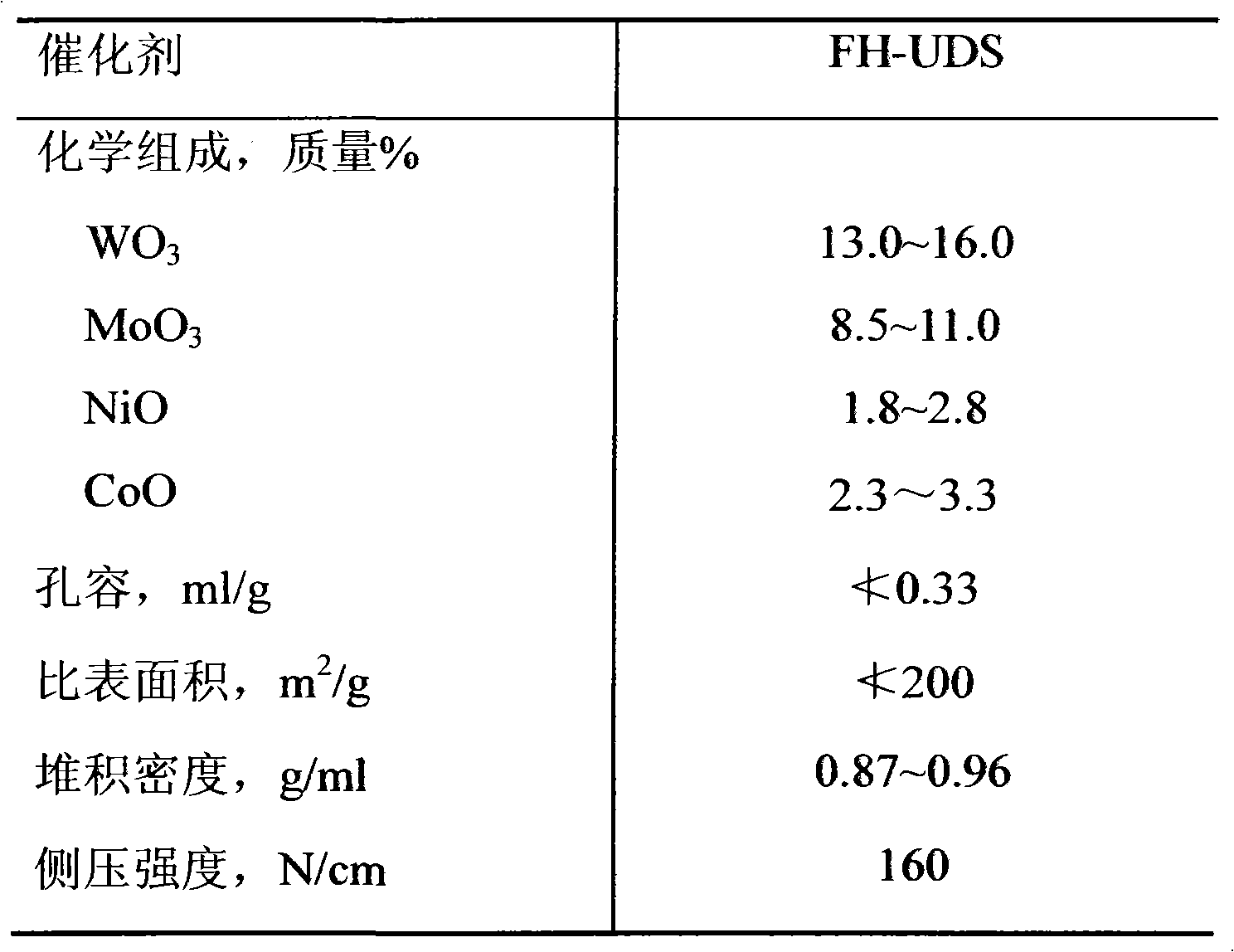

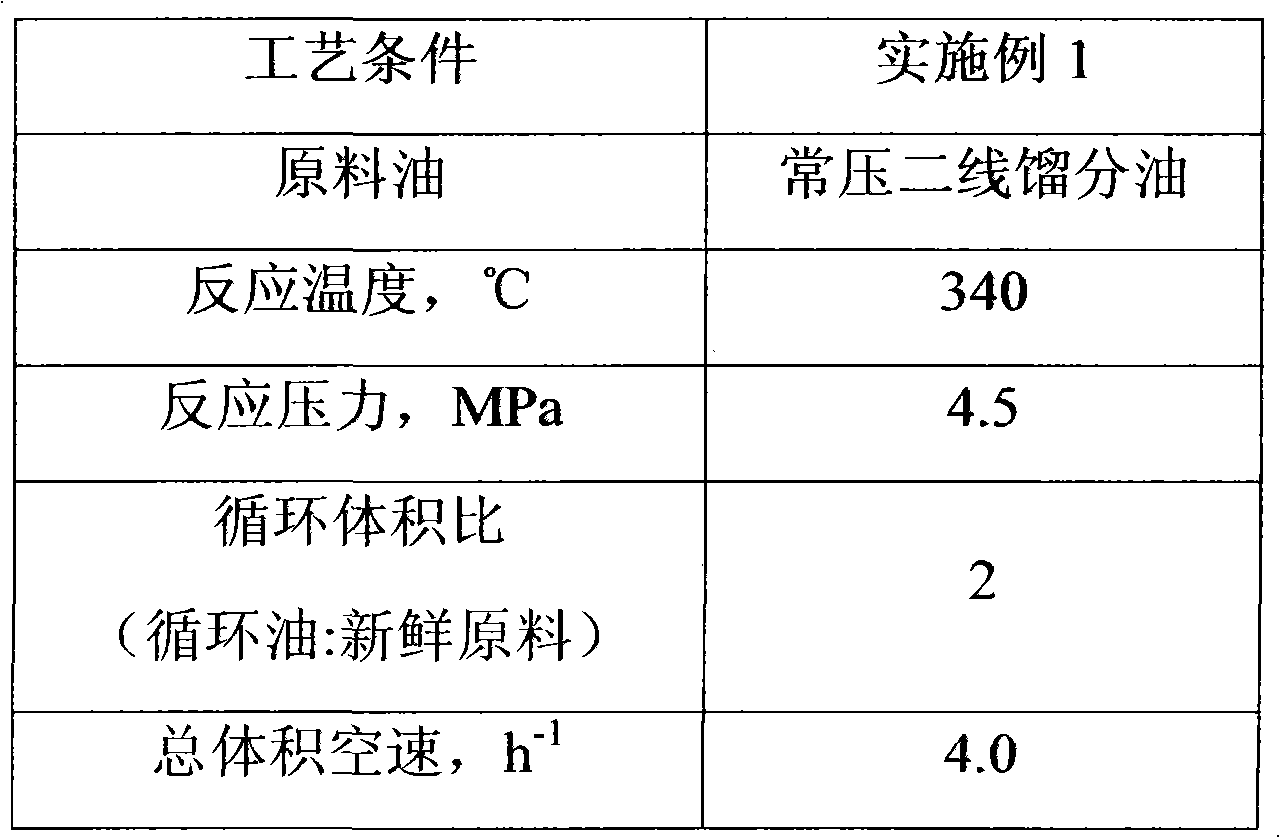

[0025] Catalyst vulcanization process for liquid-phase diesel hydrogenation process: The reactor of medium-sized diesel liquid-phase hydrogenation unit is filled with FH-UDS hydrofining catalyst developed and produced by Fushun Petrochemical Research Institute. The physical and chemical properties of the catalyst are shown in Table 1. Vulcanizing agent use C 2 S, C can be changed as needed during operation 2 S is injected into the hydrogen sulfide generation reactor, C 2 S can be mixed with some hydrocarbon oil and fed into the hydrogen sulfide generation reactor. C 2 The total amount of S is 150% of the theoretical requirement when the active metal in the hydrogenation catalyst is completely sulfided. The fresh hydrogen is pressurized to 4.5MPa and then enters the hydrogen sulfide generation reactor, while controlling the temperature of the hydrogen sulfide generation reactor within the range of 175-250°C to make hydrogen and C 2 S reacts to form hydrogen sulfide (CS 2 +...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com