Kinetic energy recovery controller for electric vehicle

A kinetic energy recovery, electric vehicle technology, applied in electric vehicles, current collectors, vehicle components, etc., can solve the problems of inconvenient promotion and application, complex design, large size, etc., to improve safety and practicability, complete functions, and improve battery life. The effect of mileage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

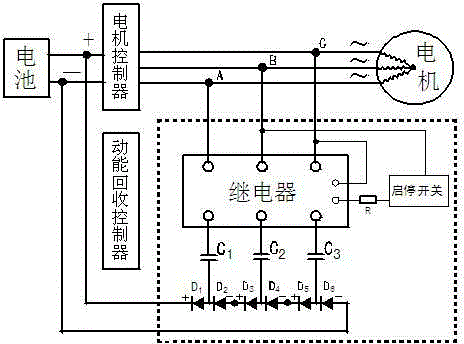

Embodiment 1

[0034] see figure 1 , this embodiment 1 discloses a kinetic energy recovery controller for an electric vehicle, including a control switch circuit, a start-stop switch, a capacitor circuit, a three-phase bridge rectifier circuit and a DC bridge series boost circuit, the kinetic energy recovery controller and the motor control The three output lines are connected in parallel to the three output lines of the motor stator. The three output lines output the A, B, and C three-phase AC kinetic energy converted by the motor when the vehicle is coasting. The control switch is an AC solid state relay. Resistance-capacity current limiting, and then three-phase bridge rectification, that is, the three capacitors C1, C2, and C3 are connected in series with the relay to the three-phase AC kinetic energy of A, B, and C, and then the AC of the three-phase bridge rectifier circuit The input terminal is connected to the three-phase AC kinetic energy of A, B, C, that is, three output lines,...

Embodiment 2

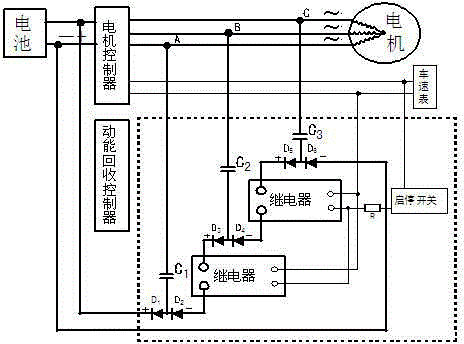

[0044] see figure 2 , figure 2 and figure 1 basically the same. The difference lies in the control switching circuit and the control switching power supply circuit, figure 1 It adopts AC relay and is installed at the AC input end of the three-phase bridge rectifier circuit, which is used to control the three-phase or any two-phase switch of the three-phase kinetic energy of A, B, and C; figure 2 It adopts a DC type relay, which is installed at the DC end of a three-phase bridge rectifier circuit, and is used as a switch to control the two series connection points in the middle of the DC bridge series boost circuit. Both circuits can realize switch control of kinetic energy recovery.

[0045] figure 1 The control switching power supply adopts the controlled dynamically changing kinetic energy itself, and its control circuit is connected to the main circuit of the controlled kinetic energy, that is, it is connected to any two of the three output lines; figure 2 The cont...

Embodiment 3

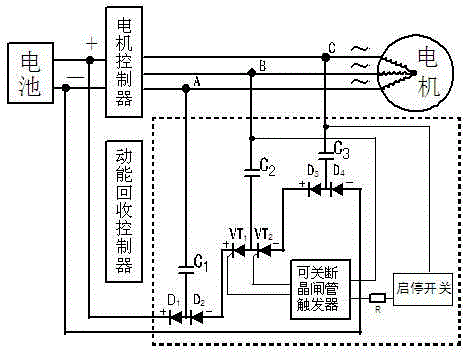

[0047] see image 3 , image 3 andfigure 1 basically the same. The difference is the controller switch circuit, figure 2 It adopts a DC relay, which is installed at the DC end of the three-phase bridge rectifier circuit, and is used as a switch to control the two series connection points in the middle of the DC bridge series boost circuit. image 3 The switchable thyristor is used as the rectifier and controllable switch of the middle B-phase bridge, and the switch of the rectifier of the B-phase bridge is controlled by the trigger of the turn-off thyristor. Both circuits can realize the switch control of kinetic energy recovery.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com