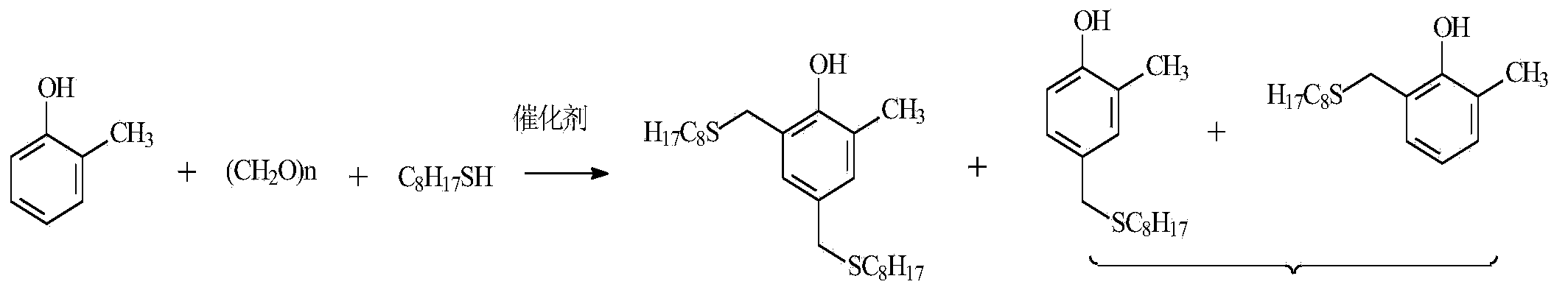

Preparation method of liquid antioxidant 4,6-di(octylsulfanylmethyl) o-cresol

An antioxidant, octylthiomethyl technology, which is applied in the field of preparation of liquid antioxidant 4,6-bis(octylthiomethyl)-o-cresol, can solve the problems of low product purity, difficult preparation, long reaction time and the like, To achieve the effect of simple industrial operation, improve product purity and shorten reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Replace the air in the 2000 liter reactor with nitrogen to pass. Add 400kg of o-cresol (3.699kmol, molar ratio is 1.0), n-octyl mercaptan 1055kg (7.212kmol, molar ratio 1.95) and paraformaldehyde 278kg (9.257kmol, molar ratio 2.50) into the reactor, and then inject 50kg of 95% ethanol, 7.8kg of industrial sodium carbonate solid (0.074kmol, molar ratio 0.02) was put into it. Turn on the stirring and condenser cooling water, and add 50 kg (0.366 kmol, molar ratio 0.10) of 33% dimethylamine aqueous solution at room temperature for 30 minutes. The material was heated up under stirring to the reflux temperature, and reacted at the reflux temperature for 5 hours.

[0031] 100 kg of deionized water was added to the obtained reaction solution, and the temperature of the solution was lowered to 42° C. under stirring, then the stirring was stopped and allowed to stand for 30 minutes, and then the lower aqueous phase 1 was carefully separated to obtain an organic phase 1 . Add 1...

Embodiment 2

[0035] Replace the air in the 2000 liter reactor with nitrogen to pass. Add 400kg of o-cresol (3.699kmol, molar ratio is 1.0), n-octyl mercaptan 1080kg (7.383kmol, molar ratio 2.00) and paraformaldehyde 278kg (9.257kmol, molar ratio 2.50) into the reactor, and then inject Methanol 80kg and deionized water 5kg, input industrial potassium carbonate solid 2.6kg (0.019kmol, molar ratio 0.005). Turn on the stirring and condenser cooling water, and add 222kg (1.477kmol, molar ratio 0.40) of 33% dimethylamine aqueous solution at room temperature for 30 minutes. The material was heated up under stirring to the reflux temperature, and reacted at the reflux temperature for 10 hours.

[0036] 320 kg of deionized water was added to the obtained reaction solution, and the temperature of the solution was lowered to 40° C. under stirring, and then the stirring was stopped and allowed to stand for 60 minutes, and then the lower aqueous phase 1 was carefully separated to obtain an organic pha...

Embodiment 3

[0040] Replace the air in the 2000 liter reactor with nitrogen to pass. Add 400kg o-cresol (3.699kmol, molar ratio is 1.0), n-octyl mercaptan 1110kg (7.588kmol, 2.05) and paraformaldehyde 400kg (13.320kmol, molar ratio 3.60) into the reactor, and then add 95% Add 40kg of ethanol and 4kg of deionized water, and put in 5.1kg of industrial potassium carbonate solid (0.037kmol, molar ratio 0.010). Turn on the stirring and condenser cooling water, and add 100kg (0.665kmol, molar ratio 0.18) of 30% dimethylamine aqueous solution at room temperature for 30 minutes. The material was heated up under stirring to the reflux temperature, and reacted at the reflux temperature for 3 hours.

[0041] Add 80 kg of deionized water to the obtained reaction liquid, cool the liquid to 40° C. under stirring, then stop stirring and let stand for 40 minutes, then carefully separate the lower aqueous phase 1 to obtain the organic phase 1 . Add 12 kg of formic acid to the organic phase 1, then add 80...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com