Preparation method of porous cross-linked anion exchange membrane for diffusion dialysis

An anion exchange membrane and diffusion dialysis technology, which is applied in the field of preparation of porous cross-linked anion exchange membranes, can solve the problems of poor diffusion dialysis performance, poor purity and unsatisfactory acid/salt separation factor of anion exchange membranes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

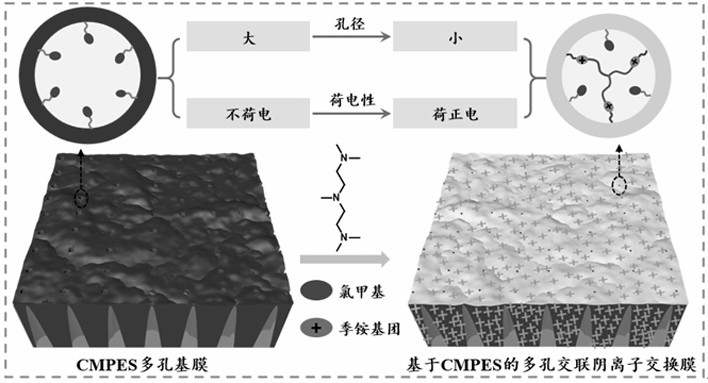

[0039] Dissolve chloromethylated polyethersulfone (CMPES) with a chloromethylation degree of 60% in N-methylpyrrolidone to form a casting solution with a concentration of 25wt%, scrape the film on a glass plate with a scraper, and control the thickness of 250 microns, and then immerse the glass plate in deionized water for phase inversion to obtain a chloromethyl polyethersulfone (CMPES) porous base membrane. The porous base membrane was immersed in an aqueous solution of pentamethyldiethylenetriamine with a concentration of 2 mol / L and a temperature of 60° C. for 12 hours to obtain a porous cross-linked anion exchange membrane functionalized with pentamethyldiethylenetriamine. The ion exchange capacity (IEC, ie the content of quaternary ammonium groups) of the membrane was measured to be 1.28 mmol / g.

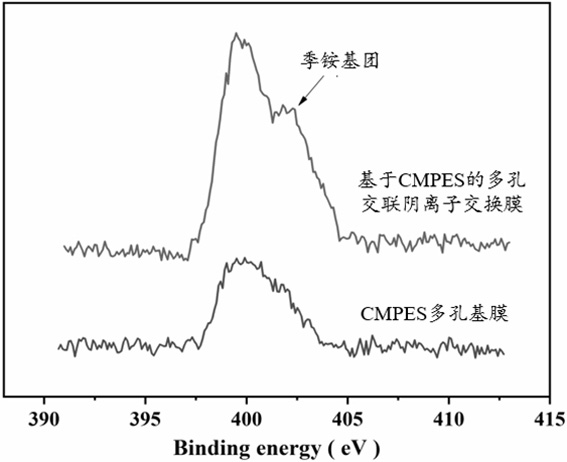

[0040] Carry out X-ray photoelectron spectroscopy (XPS) analysis to the CMPES porous base membrane and porous cross-linked anion exchange membrane prepared in this embodiment, ...

Embodiment 2

[0044] A porous cross-linked anion exchange membrane was prepared by a method similar to that of Example 1, except that the soaking time was changed to 48 hours. The ion exchange capacity of the membrane was measured to be 1.56 mmol / g. Using the porous cross-linked anion exchange membrane of this example, HCl (concentration: 1.0 mol / L) / FeCl 2 (concentration of 0.2 mol / L) mixed waste acid simulated solution for acid recovery, the measured acid dialysis coefficient of the membrane is 75.3×10 -3 m / h, the acid / salt separation factor is 4368.2.

[0045] Compared with Comparative Example 2, the ion exchange capacity of the porous cross-linked anion exchange membrane prepared in this example increased by 32.2% (from 1.18mmol / g to 1.56mmol / g), and the acid dialysis coefficient increased by 15.8% (from 65.0×10 -3 m / h increased to 75.3×10 -3 m / h), the acid / salt separation factor increased by a factor of 142.7 (from 30.4 to 4368.2), which was mainly attributed to the use of pentame...

Embodiment 3

[0047] A porous cross-linked anion exchange membrane was prepared by a method similar to that of Example 1, except that the soaking time was changed to 0.5 h, and the ion exchange capacity of the membrane was measured to be 0.53 mmol / g. Using the porous cross-linked anion exchange membrane of this example, HCl (concentration: 1.0 mol / L) / FeCl 2 (concentration of 0.2 mol / L) mixed waste acid simulated solution for acid recovery, the measured acid dialysis coefficient of the membrane is 15.6×10 -3 m / h, the acid / salt separation factor is 58.5.

[0048] Through the comparison of Examples 1-3, it can be seen that with the continuous increase of soaking time (0.5h to 48h), the ion exchange capacity of the porous cross-linked anion exchange membrane is continuously increased (from 0.53mmol / g to 1.56mmol / g) , while the acid dialysis coefficient of the membrane (from 15.6×10 -3 m / h increased to 75.3×10 -3 m / h) and the acid / salt separation factor (from 58.5 to 4368.2) were continuou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ion exchange capacity | aaaaa | aaaaa |

| Acid dialysis coefficient | aaaaa | aaaaa |

| Acid dialysis coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com