Plasma generator

A plasma and generator technology, applied in the field of plasma generators, can solve the problems of complex structure, low heat recovery utilization rate, large volume, etc., and achieve the effect of improving uniformity, cooling efficiency and strengthening disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

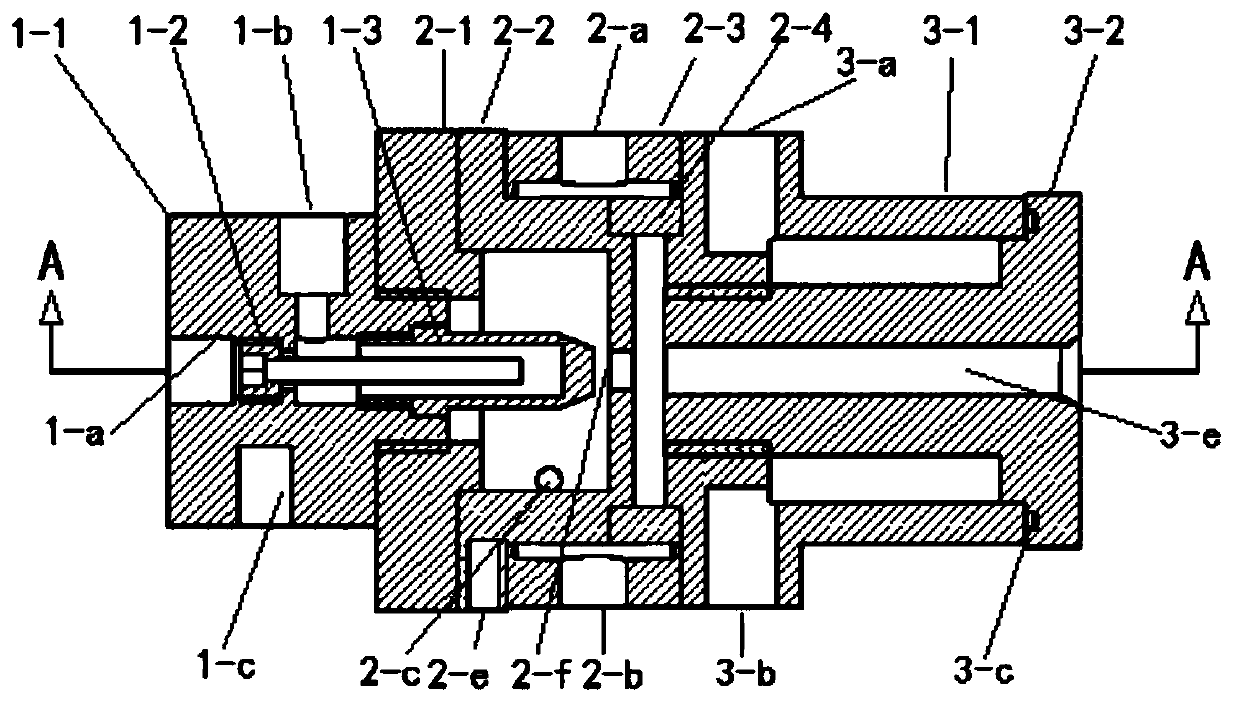

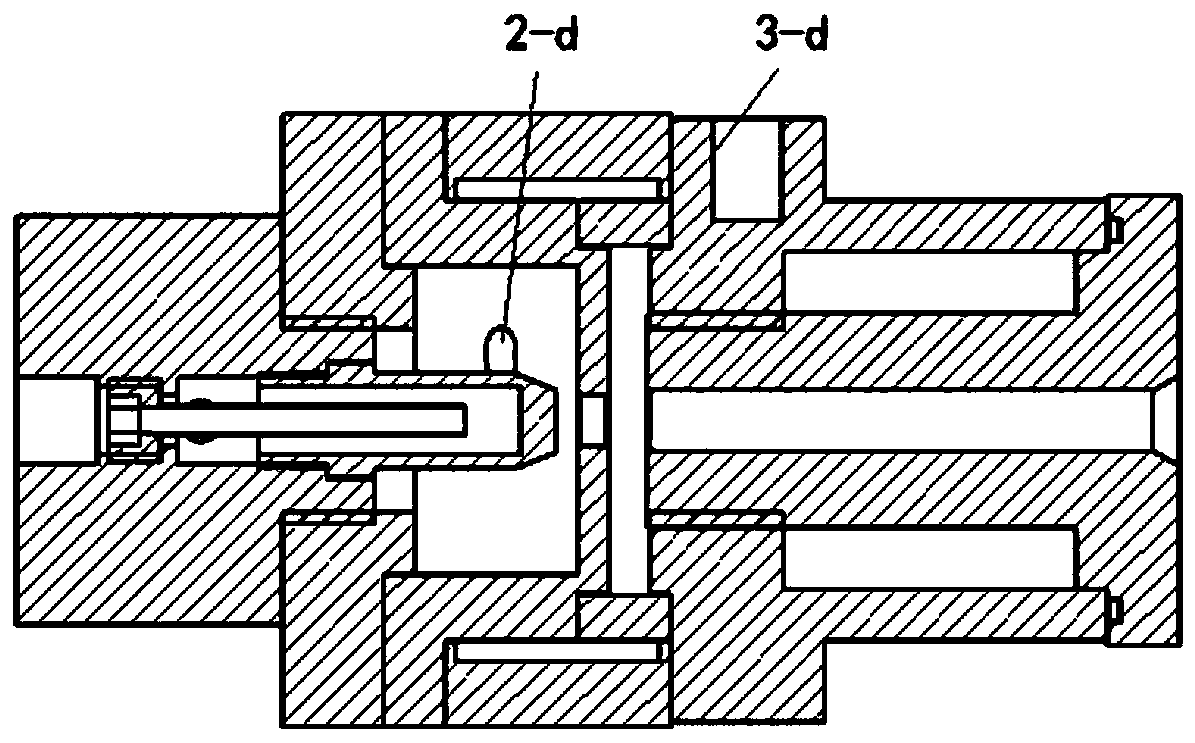

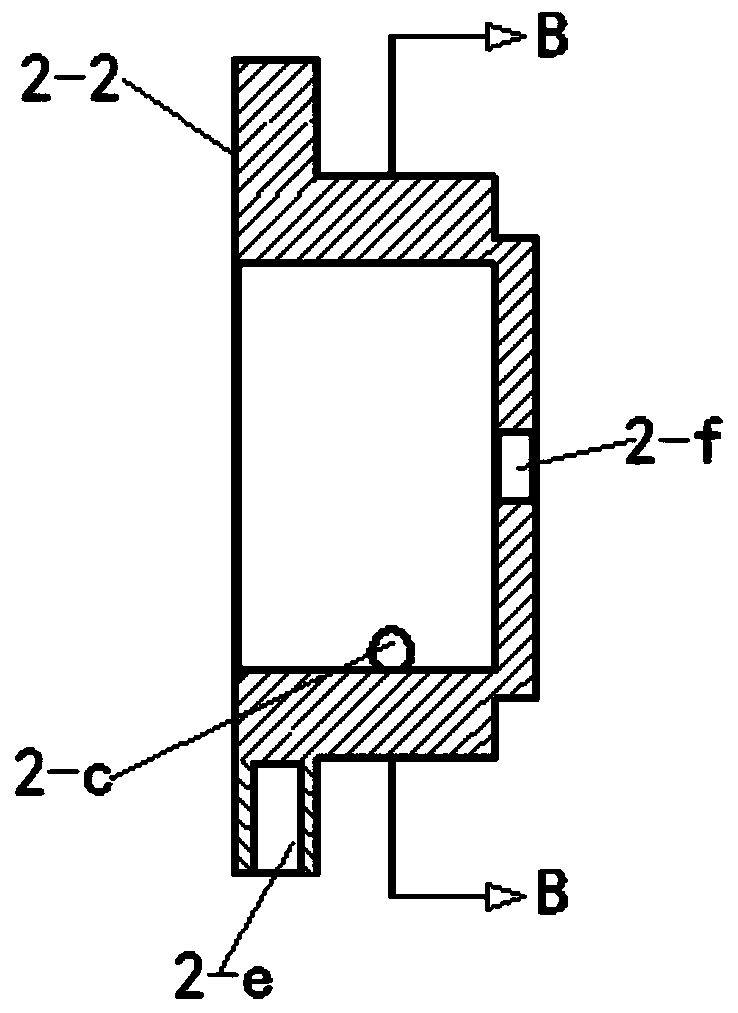

[0042] Such as figure 1 A specific implementation of the plasma generator shown includes a cathode 1, an arc starting anode 2, and an anode 3 that are coaxially connected in series in sequence, and the cathode 1 is provided with a cathode sleeve 1-1 and a cathode head 1-3 and a first cooling channel for cooling the cathode head 1-3, the anode 3 is provided with an anode casing 3-1, an anode lining 3-2 and a second cooling channel for cooling the anode lining 3-2, The arc-starting anode 2 includes: arc-starting anode lining 2-2, which is used to generate high-frequency voltage to break down the working gas to form plasma between the arc-starting anode lining 2-2 and the cathode head 1-3 after electrification, And pass to the anode 3 under the action of the gas to make the cathode 1 and the anode 3 conduct to form a stable plasma jet; the plasma generation chamber is located on the side of the arc starting anode lining 2-2 facing the cathode head 1-3, The arc starting anode 2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com