Cooling device based on vehicle injection mold equipment machining

A technology for injection molds and cooling devices, which is applied in the field of auxiliary cooling equipment for automobile processing, and can solve problems such as unreasonable optimization of the structure of heat exchange fins, poor blowing cooling effect of external cooling water, low heat exchange efficiency of internal cooling water, etc. , to achieve the effect of ensuring cooling and cooling effect, improving heat exchange and heat dissipation efficiency, and increasing circulation path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

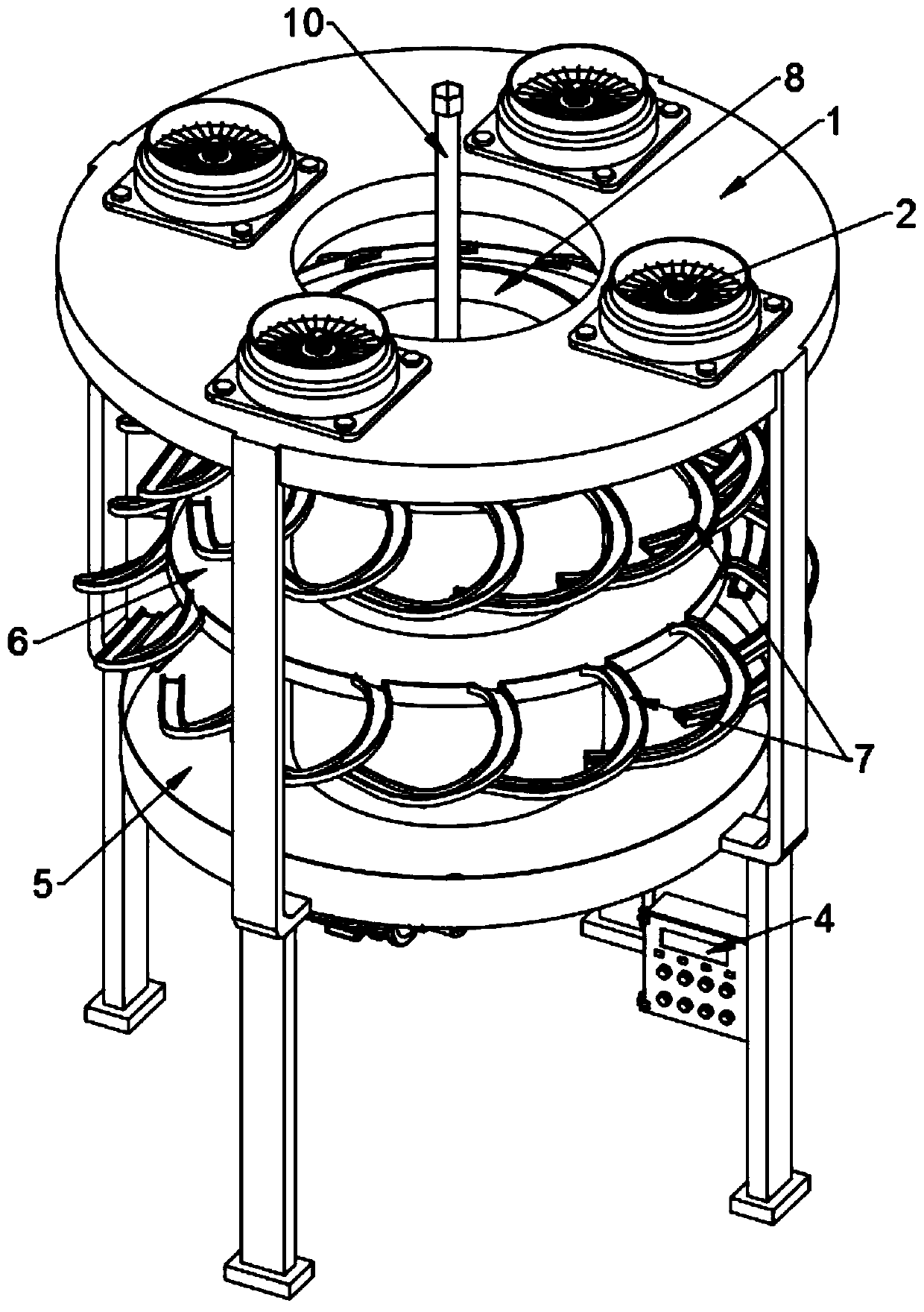

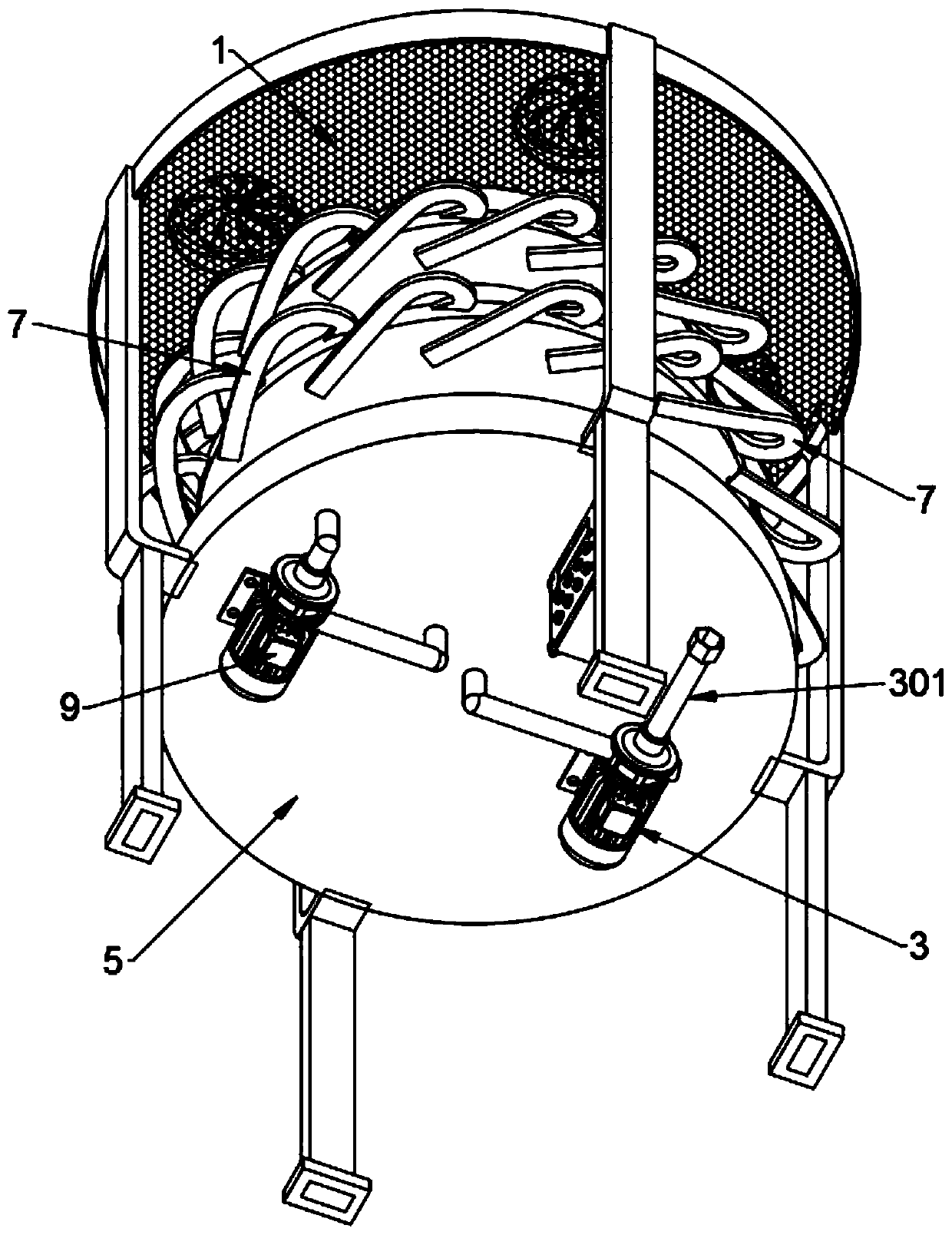

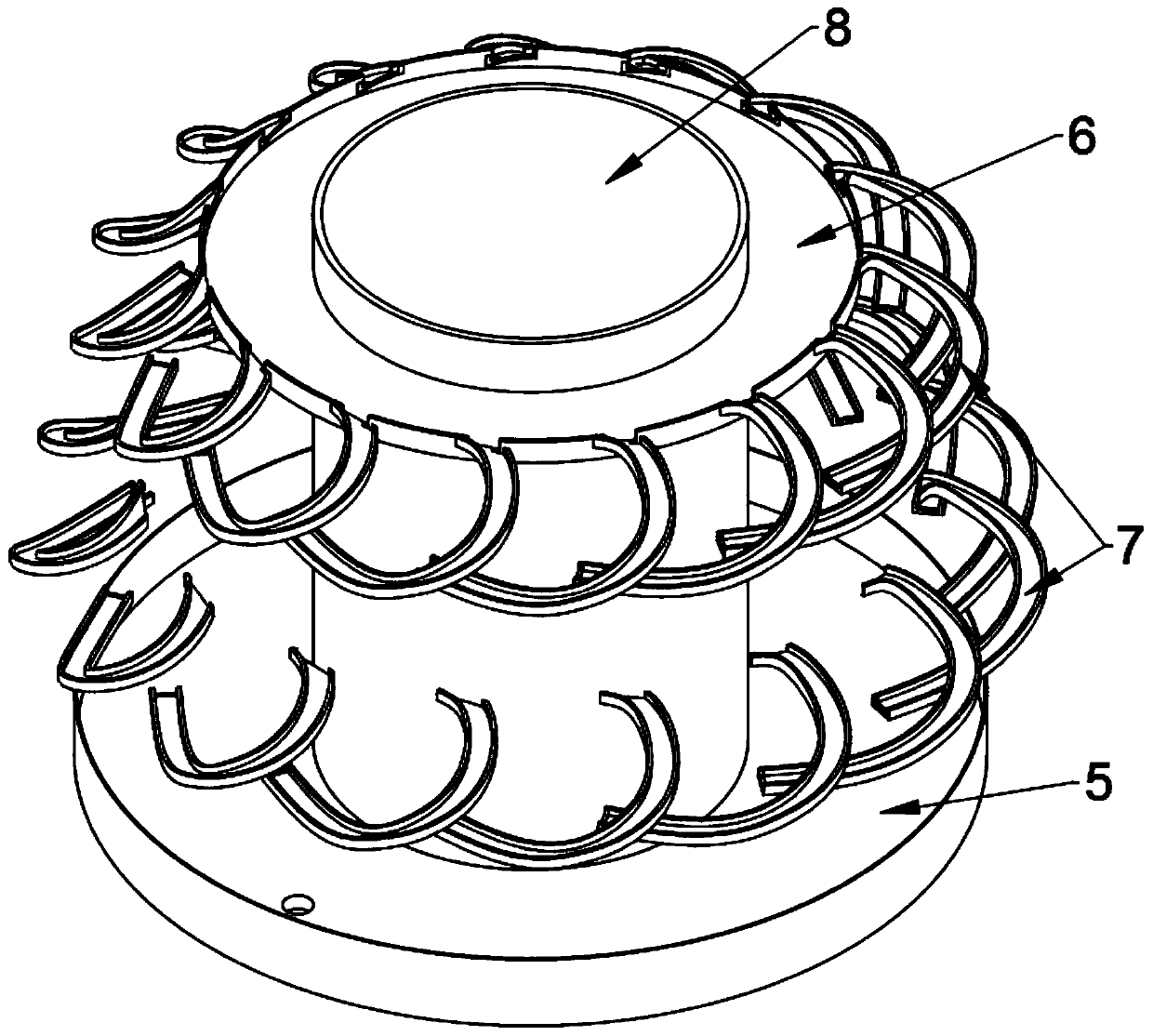

[0025] as attached figure 1 to attach Figure 6 Shown:

[0026] The invention provides a cooling device based on the processing of automobile injection mold equipment, which includes an installation cover 1, a heat dissipation fan 2, an inner circulation cooling pump 3, a circulation cooling outlet pipe 301, a control electric box 4, a water receiving tray 5, and an overflow tray 6. Aqueduct groove 7, water cylinder 8, external cooling pump 9, internal water inlet pipe 10, heat exchange plate 11, water cover 12 and bent heat exchange fins 13; the middle support of the bottom plate of the water receiving plate 5 A water cylinder 8 is welded, and a water overflow pan 6 is sleeved and welded at the middle section and the top position of the water cylinder 8; four supporting plates are arranged in a circular array on the outer wall of the water receiving pan 5, and the four supporting plates There is an installation cover 1 welded on the top support, and the installation cover 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com