Reactive coke regeneration tower

A technology of activated coke regeneration and shell, applied in filter regeneration, filtration separation, petroleum industry, etc., can solve the problems of low heat exchange efficiency and insufficient heat exchange, achieve sufficient heat exchange, prevent spontaneous combustion of coke, and prolong circulation effect of path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

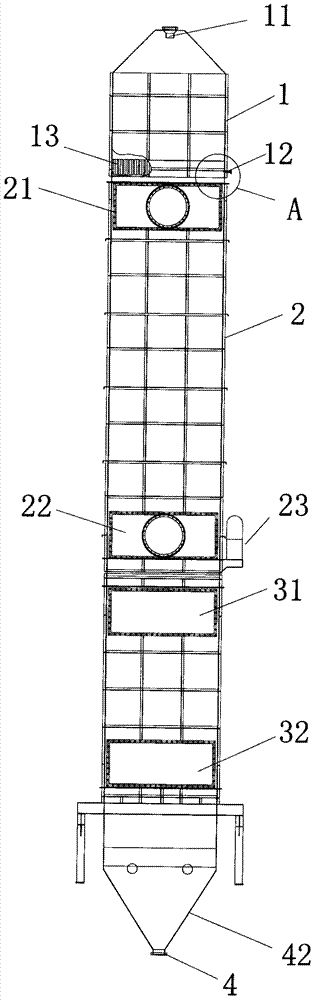

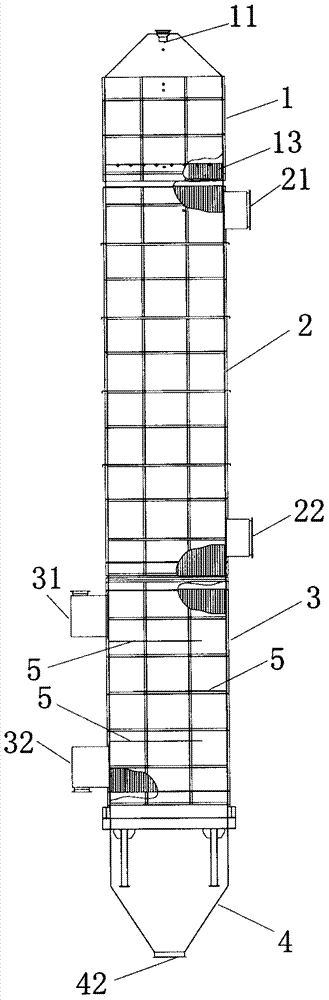

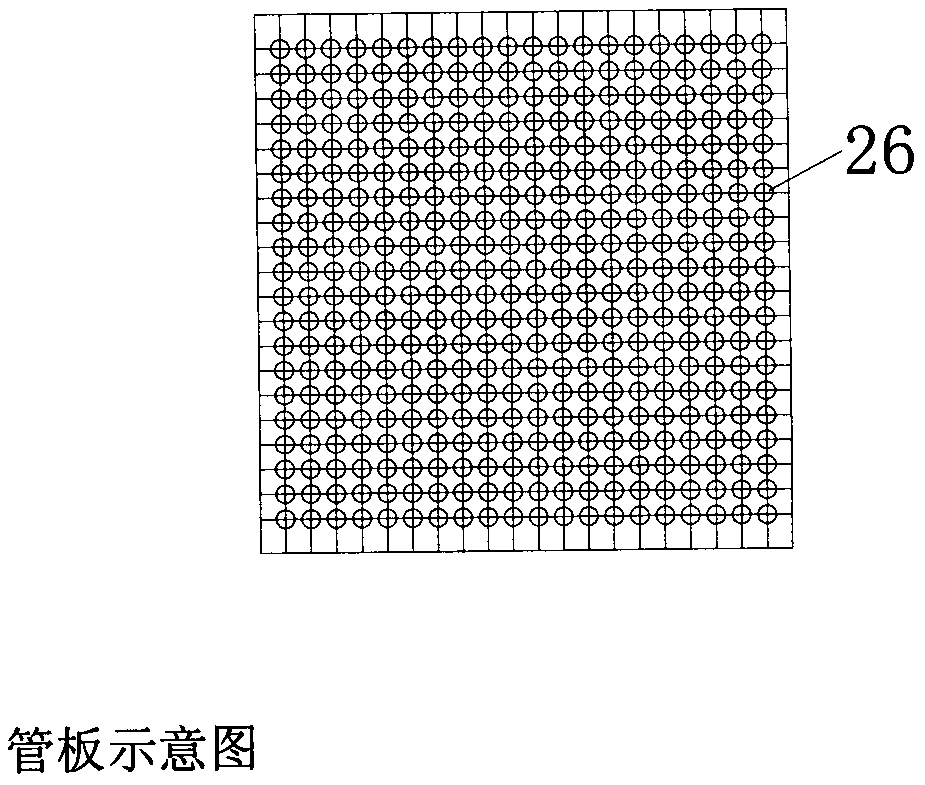

[0022] Example 1 as Figure 1 to Figure 6 As shown, the active coke regeneration tower of this embodiment includes a charging section 1, a heating section 2, a cooling section 3, and a feeding section 4 arranged in the shell. The charging section 1 is arranged in a conical shape, and the top of the charging section 1 The cross-sectional area is smaller than the cross-sectional area of its bottom; the feeding port 11 at the top of the charging section 1 is funnel-shaped, and is used to add the coke to be activated into the activated coke regeneration tower; a plurality of feeding pipes 26 are vertically arranged in the heating section 2, each The top end of the feeding pipe 26 is sleeved in the first tube plate 16 having a mesh adapted to the feeding pipe 26, and the bottom end of each feeding pipe 26 is sleeved in the first tube plate 16 having a mesh matching the feeding pipe 26. Inside the second tube sheet 24, so that the first tube sheet 16, the second tube sheet 24 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com