Process for recycling waste dustfree paper and equipment thereof

A dust-free paper and process technology, applied in recycling technology, paper recycling, raw material separation, etc., can solve problems such as unstable product quality, poor product quality, and heavy labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

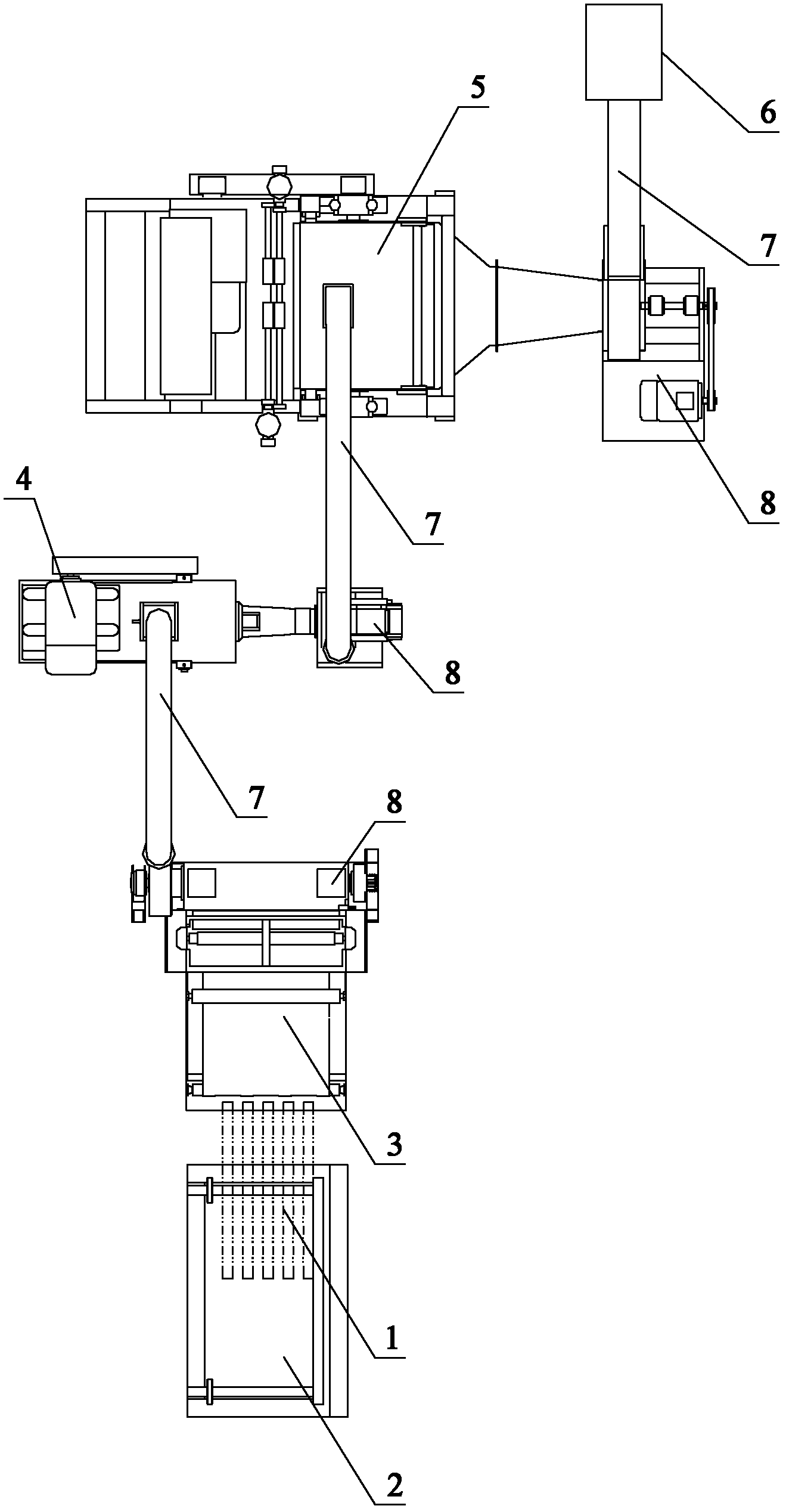

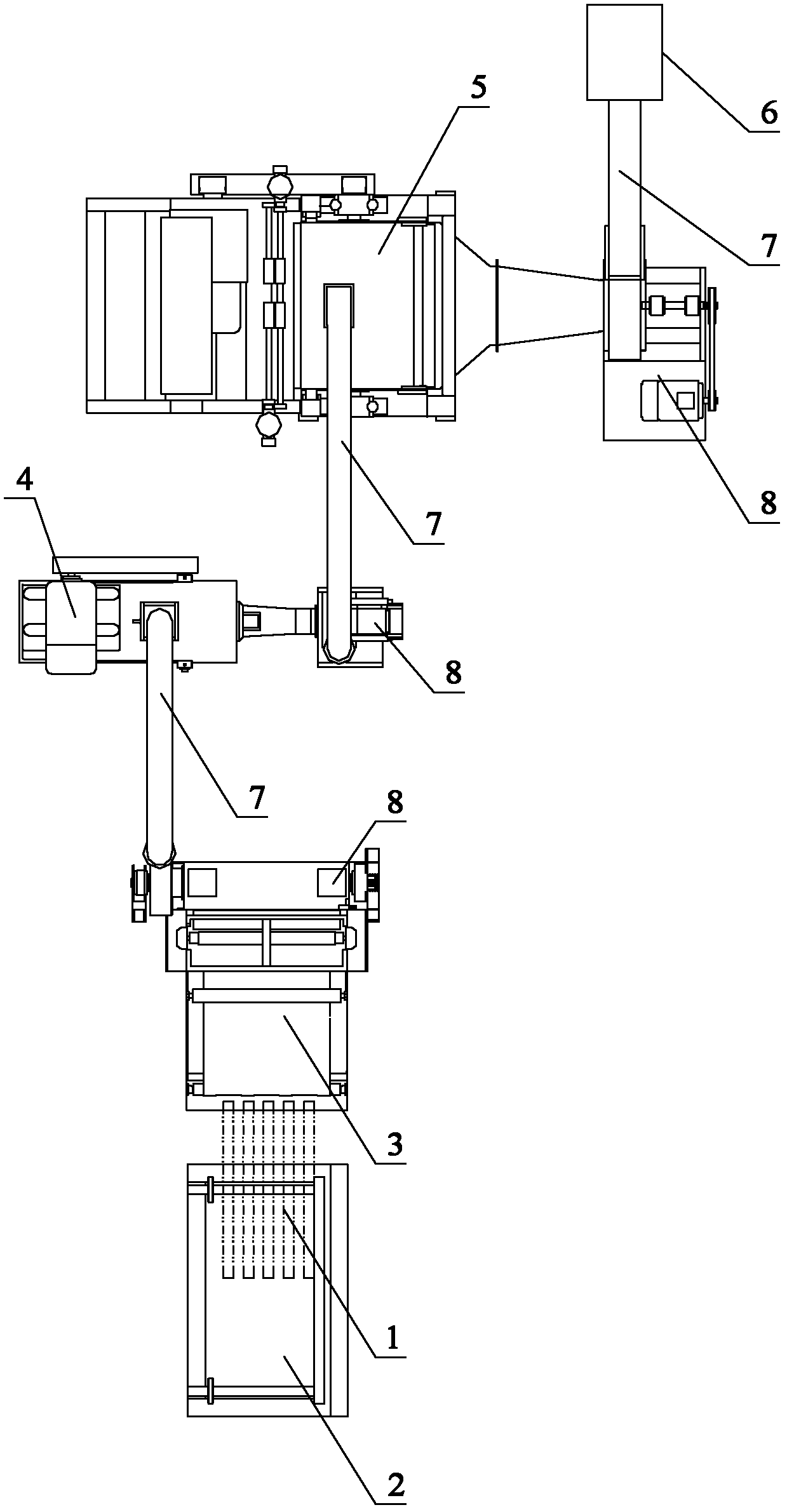

[0021] Such as figure 1 Shown, a kind of waste dust-free paper recycling process comprises the following steps,

[0022] 1) Collect and process the dust-free paper waste into a waste roll 1, the waste roll 1 is circular, with a roll diameter of 400-1500mm,

[0023] 2) Then the waste roll 1 is sent into the coarse pulverizer 3 through the feeding device 2, the coarse pulverizer 3 adopts a mace type pulverizer, and the feeding speed of the feeding device 2 is 0-16m / min,

[0024] 3) Use a mace-type pulverizer with a 15kw pulverizing main motor to crush the waste volume 1 into flake bulk materials with a diameter of less than 50mm. The flake bulk materials with a diameter of less than 50mm can meet the needs of subsequent fine crushing.

[0025] 4) The flake bulk material enters the first-stage fine grinder 4 with a 75kw crushing main motor through a pipeline 7 with a diameter of 250mm under the action of a 7.5kw blower fan. The first-stage fine grinder 4 adopts a sawtooth grinde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com