Gas turbine

A gas turbine and combustion gas technology, which is applied in the direction of gas turbine devices, mechanical equipment, engine functions, etc., can solve the problems of reduced driving force recovery efficiency and gas turbine performance, and achieve the effect of suppressing the reduction of recovery efficiency and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

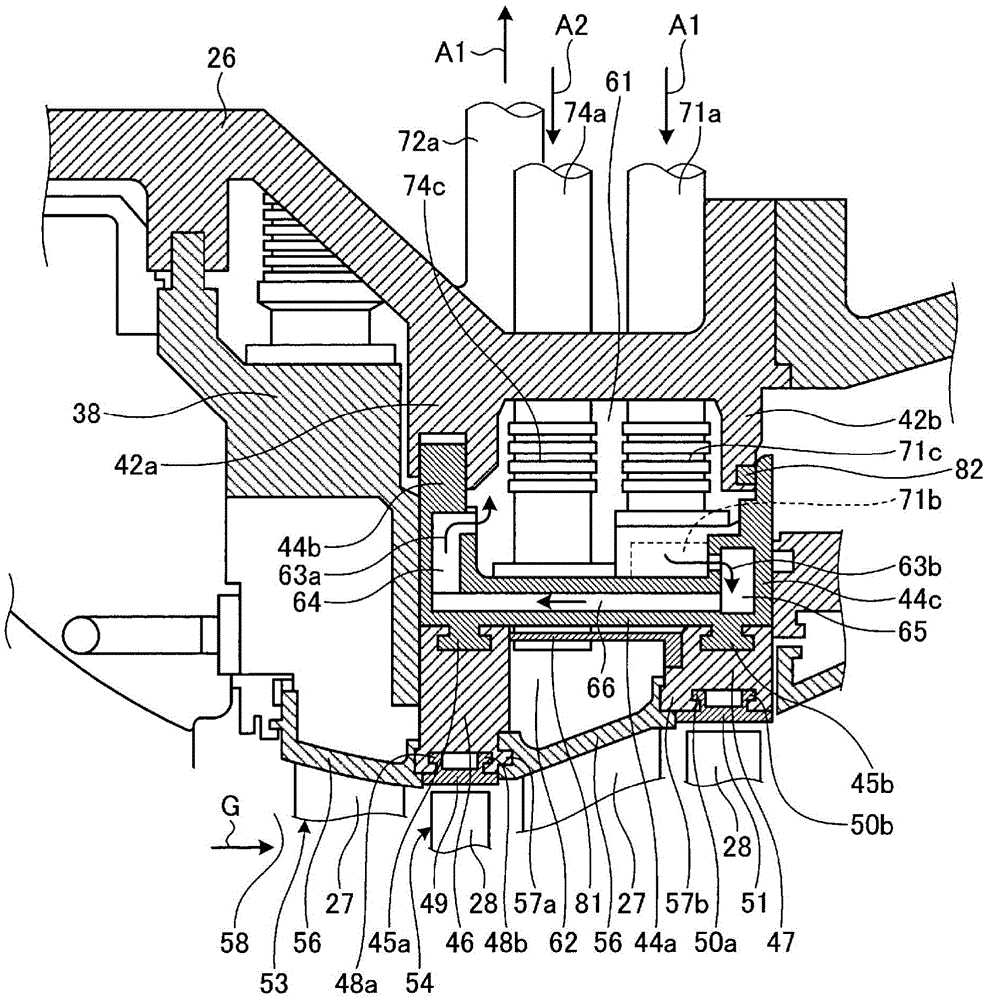

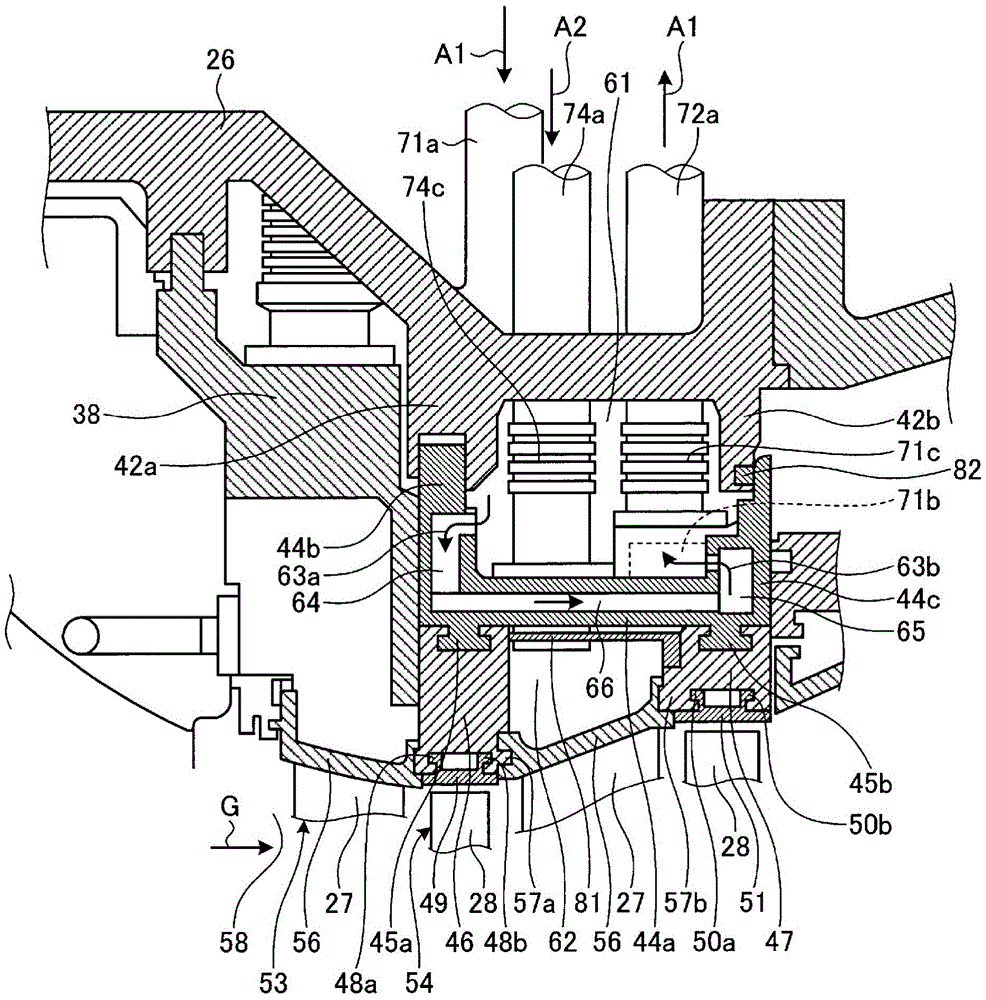

[0044] Hereinafter, preferred embodiments of the gas turbine according to the present invention will be described in detail with reference to the drawings. In addition, this invention is not limited to this embodiment, Moreover, when there are several embodiment, the structure which combined each embodiment is included.

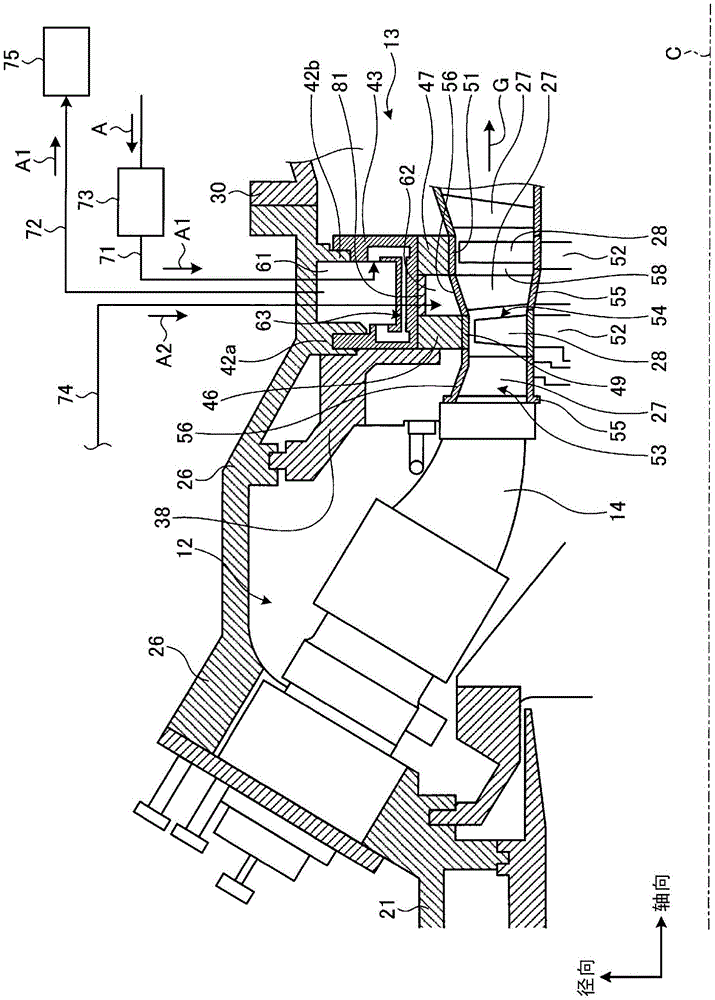

[0045] Figure 7 It is a schematic diagram showing the overall configuration of the gas turbine according to the present embodiment.

[0046] Such as Figure 7 As shown, the gas turbine of this embodiment is constituted by a compressor 11 , a combustor 12 and a turbine 13 . The gas turbine is coaxially connected with a generator (not shown), and can generate electricity.

[0047] The compressor 11 has an air inlet 20 for introducing air, and inlet guide vanes (IGV: Inlet Guide Vane) 22 are arranged in the compressor chamber 21, and are arranged alternately along the flow direction of the air (the axial direction of the rotor 32 described later). A plurali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com