Drying and crushing integrated device and using method

A drying and crushing hammer technology, applied in drying gas arrangement, drying, dryer and other directions, can solve the problems of pollution, single drying temperature, reducing the efficiency of the crushing process, etc., to improve the preparation efficiency, adapt to a wide range, and avoid clogging Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the embodiments in the drawings:

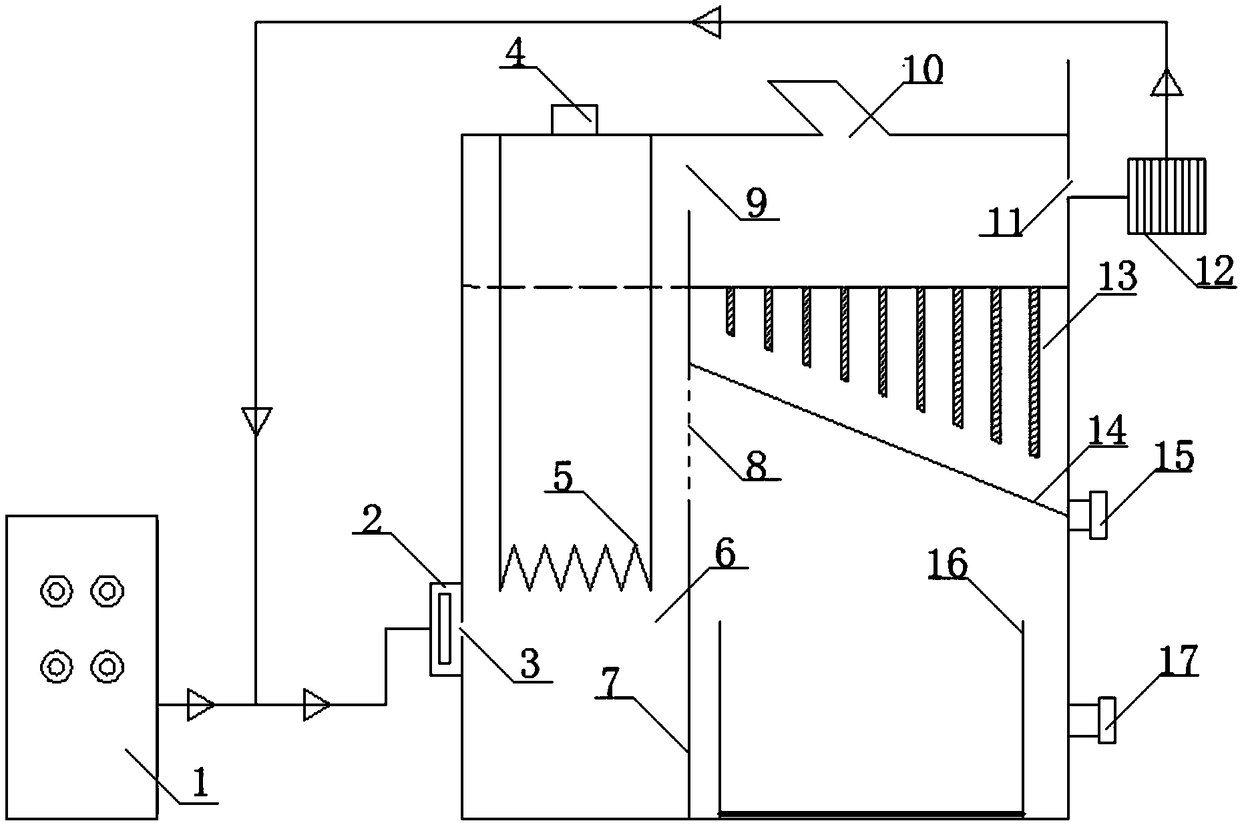

[0021] Such as figure 1 As shown, an integrated device for drying and crushing low-rank coal of the present invention includes an air compressor 1, a cabinet, and a bag filter 12, and the cabinet is provided with two boxes that divide it into left and right boxes. The partition 7, the left box body is the air collecting box 6, the right box body is the screening box, the lower part of the air collecting box 6 is provided with a first air inlet 3 connected with the output pipeline of the air compressor 1. A mass flow meter 2 is provided at the entrance of the first air inlet 3; the upper part of the screening box is provided with a bag filter 12 connected to the output pipeline of the air compressor 1, and the air collecting box 6 is provided with There is a heating wire 5 controlled by a heating wire power switch 4. The top of the screening box is provided with an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com