Small-compacted-volume solid waste treatment equipment

A technology of solid waste and treatment equipment, which is applied in the direction of solid waste removal, grain treatment, presses, etc., which can solve the problems of large volume, land occupation, and poor waste compression effect, so as to reduce the steps of manual operation and improve Efficiency, the effect of reducing the footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0022] All the features disclosed in this specification, except mutually exclusive features and / or steps, can be combined in any way.

[0023] Combine below Figure 1-Figure 3 The present invention will be described in detail.

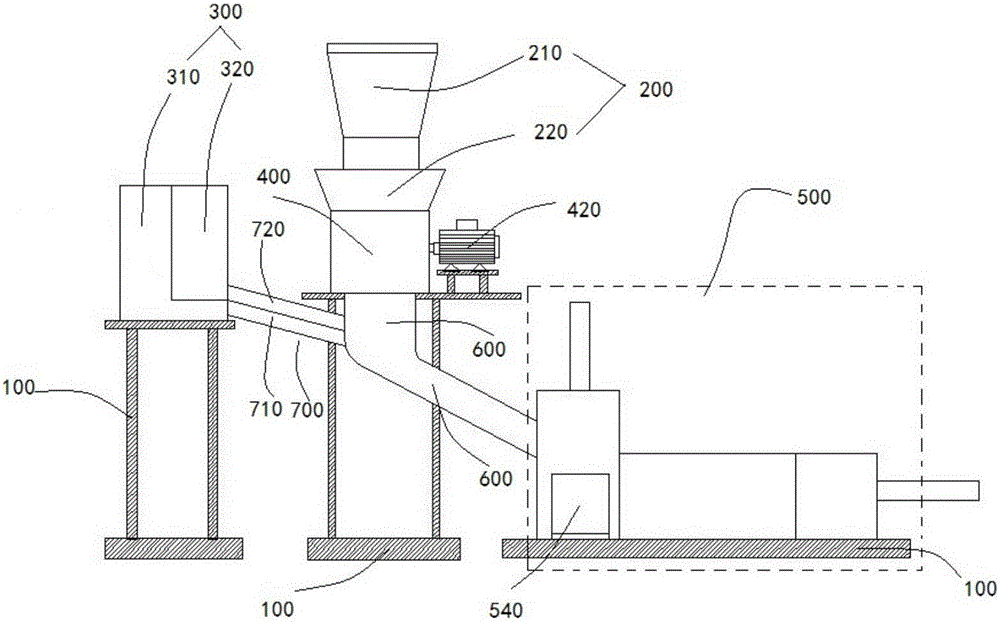

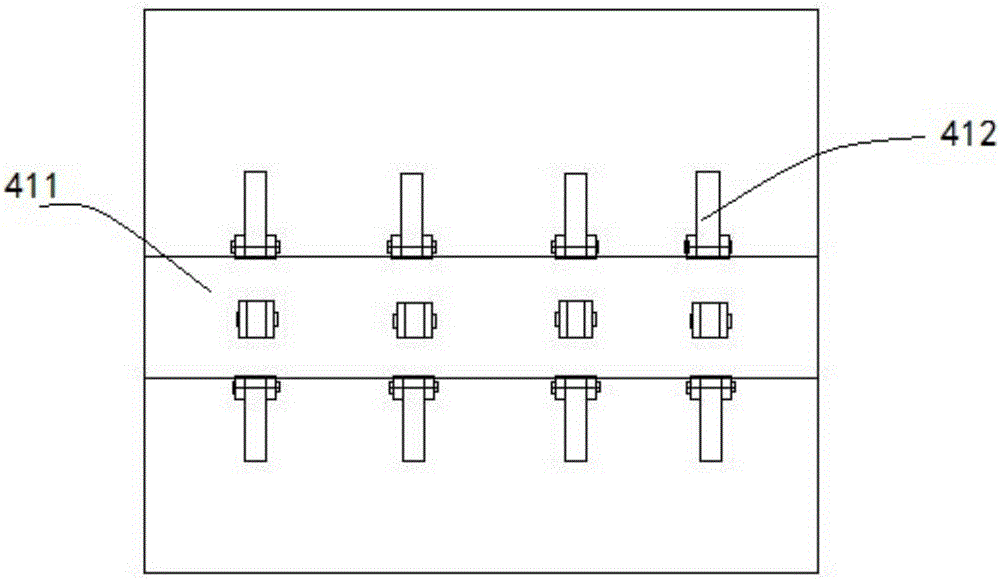

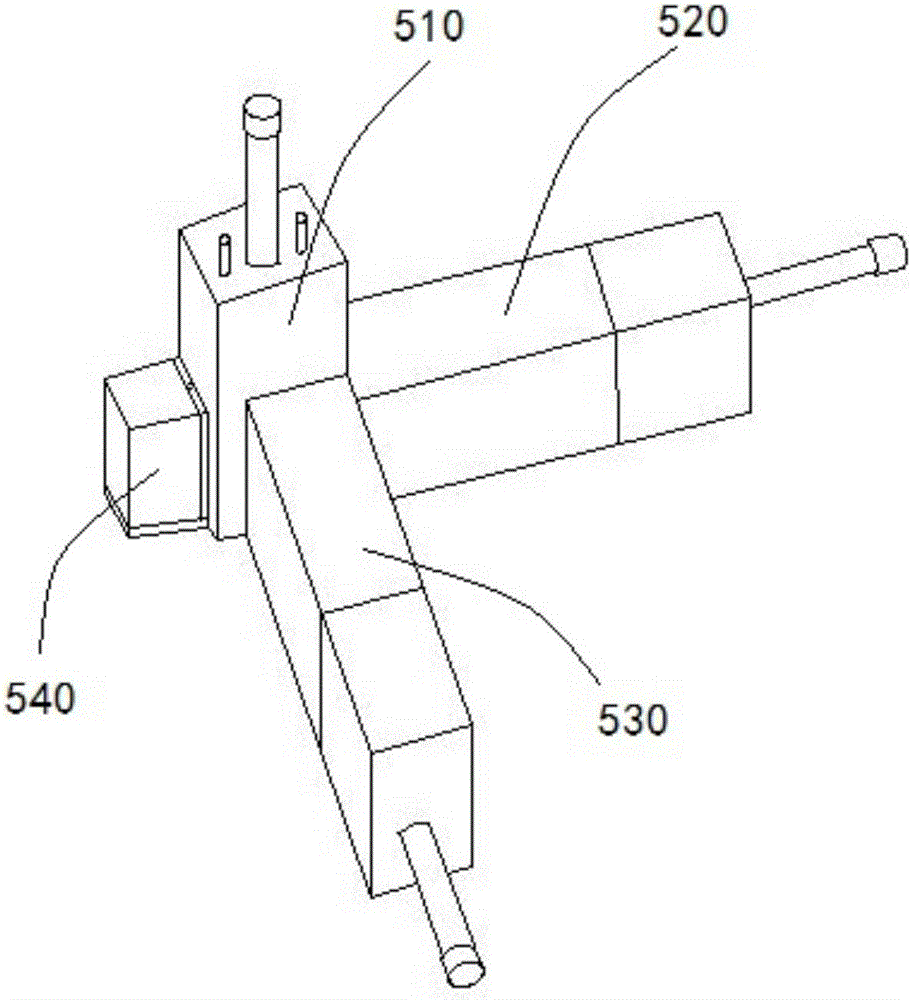

[0024] Such as Figure 1-3 As shown, a small compacted volume solid waste treatment equipment includes a frame 100, and a feeding mechanism 200, an acid and alkali storage mechanism 300, a crushing mechanism 400 and a compacting mechanism 500 located on the frame;

[0025] The crushing mechanism 400 is connected in series below the feeding mechanism 200, and the crushing mechanism 400 is connected to the feeding port of the compacting mechanism 500 through a pipeline one 600;

[0026] The outlet of the acid and alkali liquid storage mechanism 300 is connected with the first pipeline 600 through the second pipeline 700 .

[0027] The feeding mechanism 200 includes a hopper 210 and a stirring mechanism 220 located below the hopper 210 and connected in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com