D-type pulping equipment which is based on airflow vortex and conducts stirring and pulping

An air vortex and pulping technology, which is used in textile and papermaking, raw material separation, papermaking, etc., can solve the problems of low pulp quality and low efficiency, and achieve the effect of accelerating vortex crushing and facilitating water injection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

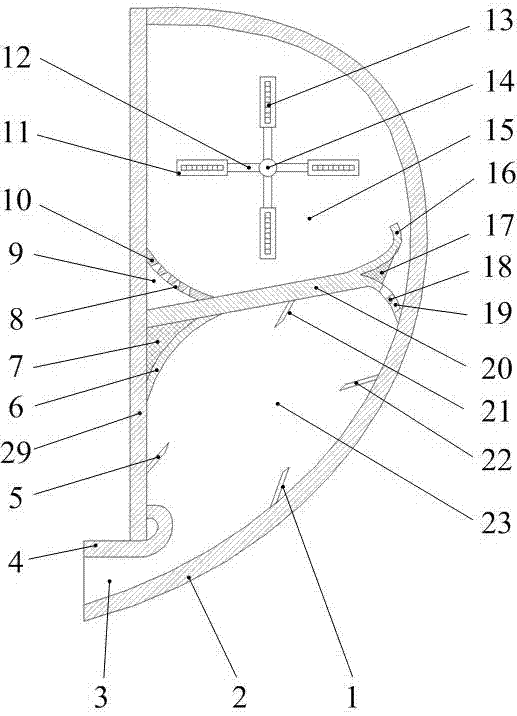

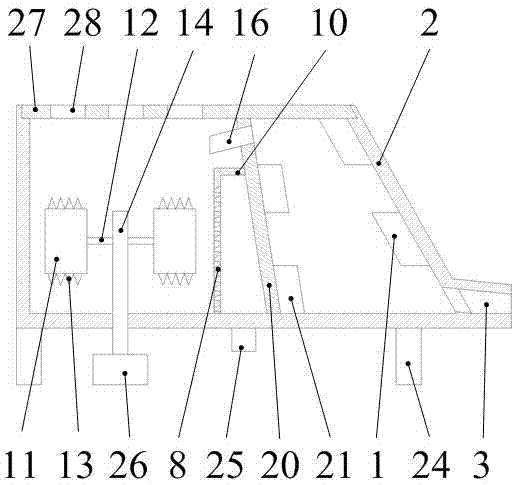

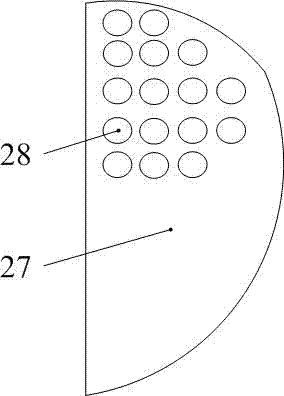

[0034] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a D-type pulping equipment based on airflow vortex and stirring and pulping according to the present invention mainly includes a D-shaped barrel device, an airflow vortex pulping device, a stirring pulping device and a fine pulp storage device, and the airflow vortex The rotary pulping device, stirring pulping device and fine pulp storage device are arranged together in the D-shaped barrel device. The airflow vortex pulping device, stirring pulping device and fine pulp storage device are three-sided structure devices respectively, and the airflow vortex The pulping device, the stirring pulping device and the fine pulp storage device are respectively adjacent to each other.

[0035] In the present invention, the D-type pulping equipment is mainly divided into an airflow vortex pulping device, a stirring pulping device and a fine pulp storage device. Through this design, air crushing, liquid crushing and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com