Environment-friendly cement and production method thereof

A technology of green cement and cement clinker, which is applied in cement production, etc., can solve the problems of large amount of cement slag material, large amount of dust in the production process, and low output of a single machine, so as to reduce the amount of use, improve the degree of homogenization, and increase the amount of blending Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

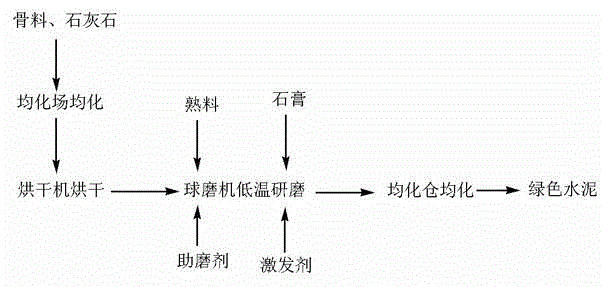

Method used

Image

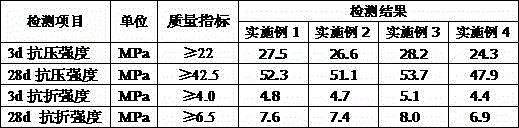

Examples

Embodiment 1

[0027] 90 parts of thermal power plant waste slag and 10 parts of crushed limestone are put into the homogenization field, homogenized storage, pumped from the homogenization field into the high-efficiency energy-saving dryer, and the heat generated by coal combustion is used to rotate and dry to a moisture content of 3-5. %, transported from the hoist at the tail of the dryer into the homogenization bin; according to the ratio of the weight fraction of the following materials:

[0028] 60 for dry mixed material; 40 for cement clinker;

[0029] Gypsum 5; Triethanolamine 0.03;

[0030] Yuanming powder 3, aluminum hydroxide 2;

[0031] Add it into the ball mill, spray 0.5MPa high-pressure water into the ball mill, so that the temperature of the ball mill process is controlled at 130°C, and the material coming out of the grinding head of the ball mill, that is, cement, is transported into the finished product homogenization bin by a hoist, and passed through the homogenization p...

Embodiment 2

[0033] Put 80 parts of manganese and manganese alloy factory waste slag and 20 parts of crushed limestone into the homogenization field, homogenize the reserve, use a pump to add from the homogenization field to the high-efficiency energy-saving dryer, and use the heat generated by coal combustion to rotate and dry to moisture 3 to 5%, transported from the hoist at the tail of the dryer into the homogenization bin; according to the ratio of the weight of the following materials:

[0034] Dry mixed material is 50; cement clinker is 32;

[0035] Gypsum 5; Triethanolamine Phosphate 0.05;

[0036] alum3.

[0037] Put it into the ball mill, spray 1MPa high-pressure water into the ball mill, so that the temperature of the ball mill process is controlled at 100-102°C, and the material that comes out of the grinding head of the ball mill, that is, cement, is transported into the finished product homogenization bin by a hoist, and passed through The air generated at the bottom of the...

Embodiment 3

[0039] Put 85 parts of iron and steel plant waste slag and phosphoric acid plant waste slag and 15 parts of crushed limestone into the homogenization field for homogenization and storage, and pump them from the homogenization field into the high-efficiency energy-saving dryer, and use the heat generated by coal combustion to rotate and dry to The moisture content is 3-5%, and it is transported into the homogenization bin from the elevator at the tail of the dryer; according to the proportion of the weight of the following materials

[0040] Dry mixed material is 55; cement clinker is 37;

[0041] Gypsum 4; Diethanolamine Phosphate 0.04;

[0042] alum4.

[0043] Put it into the ball mill, spray 0.8MPa high-pressure water into the ball mill, so that the temperature of the ball mill process is controlled at 108-112°C, and the material coming out of the grinding head of the ball mill, that is, cement, is transported into the homogenization bin of the finished product by the eleva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com