Kitchen waste treatment system

A technology for processing system and kitchen waste, applied in chemical instruments and methods, solid waste removal, transportation and packaging, etc., can solve the problems of secondary pollution, harmful gas generation, disadvantageous resource saving, etc. The effect of high environmental and recycling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings.

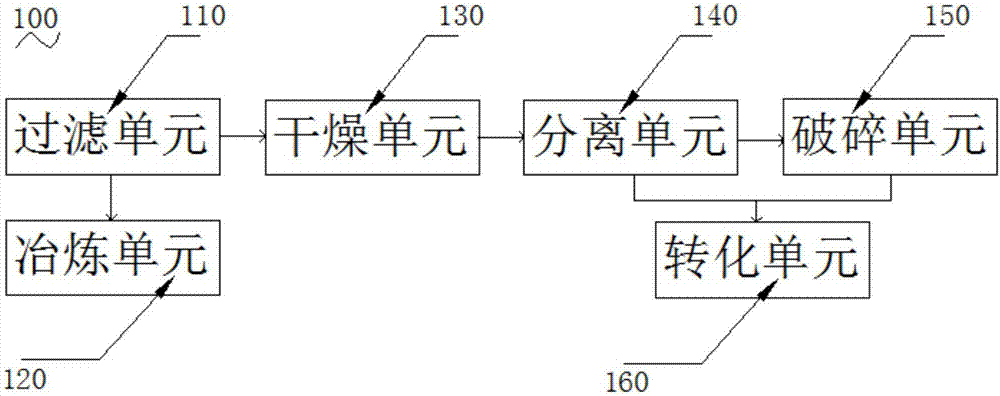

[0038] Such as figure 1 Shown is a working principle diagram of the present invention.

[0039] The kitchen waste treatment system 100 includes a filter unit 110 for filtering liquid waste, a smelting unit 120 connected to the filter unit 110 for smelting the filtered liquid waste to obtain biodiesel, and connected to the filter unit 110 for smelting The drying unit 130 for drying the filtered solid waste, the separation unit 140 connected to the drying unit 130 for separating the bone waste in the dried solid waste, and the separation unit 140 for crushing the bone waste The crushing unit 150, the conversion unit 160 connected to the separation unit 140 and the crushing unit 150 for fermenting solid waste into feed.

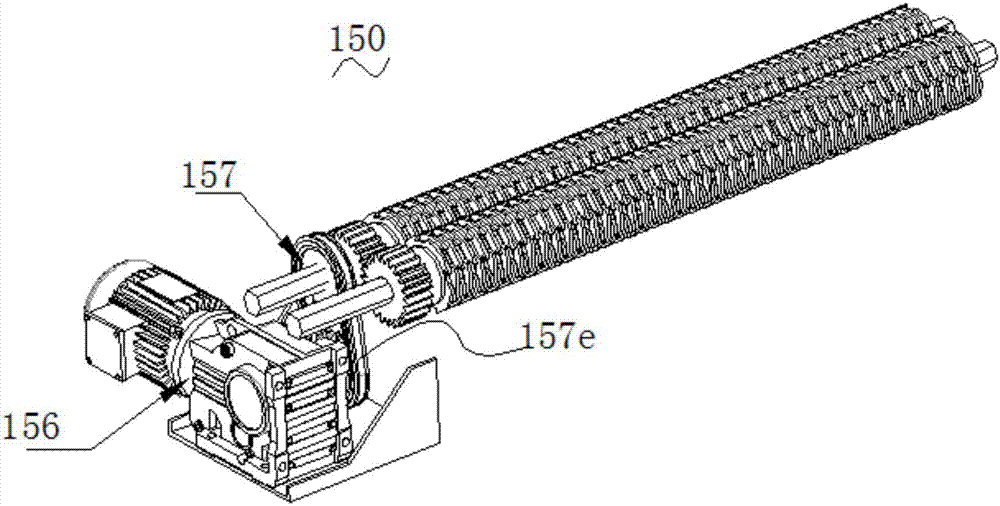

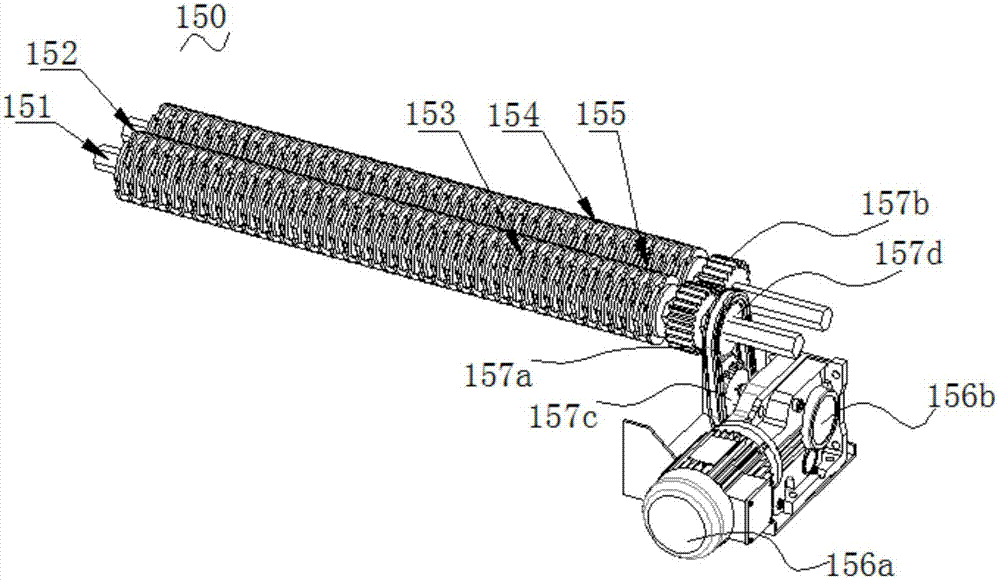

[0040] Such as figure 2 and image 3 Shown are perspective views of different viewing angles of the crushing unit of the present invention.

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com