Novel jaw-type crusher

A jaw crusher, a new type of technology, applied in the direction of grain processing, etc., can solve the problems of poor crushing effect of ore extrusion, achieve the effects of weakening the rubbing effect, reducing wear and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

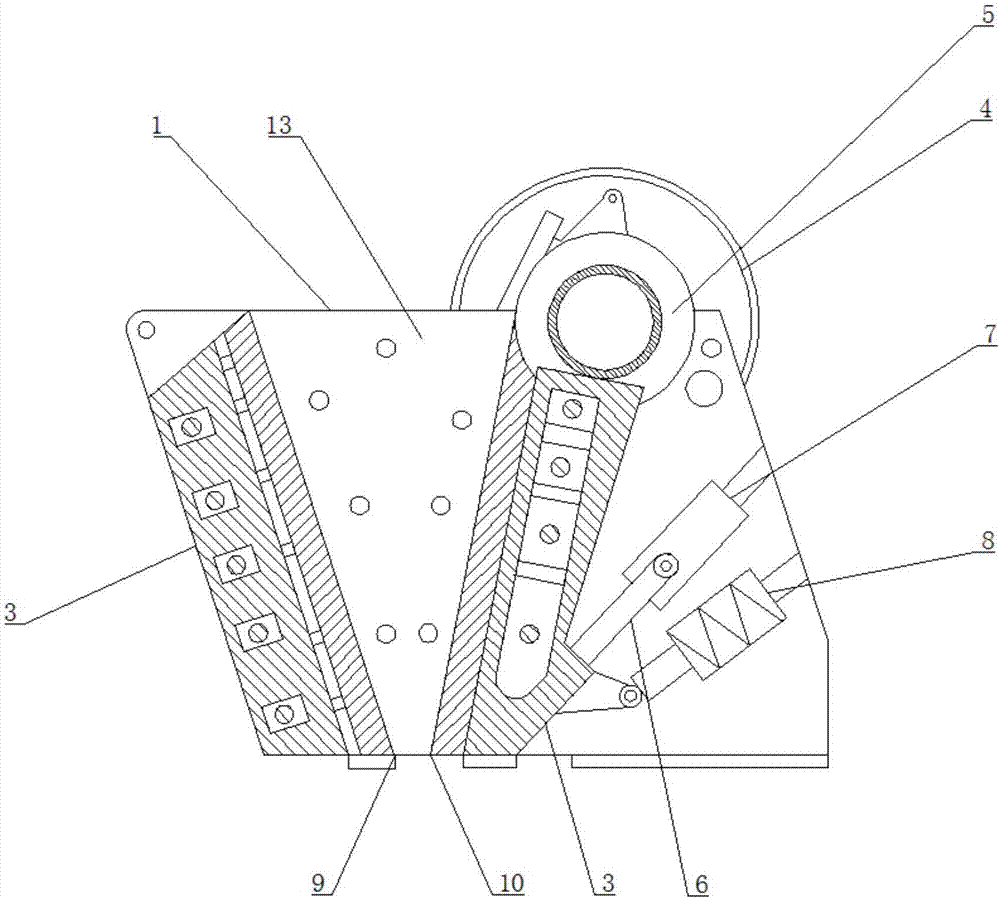

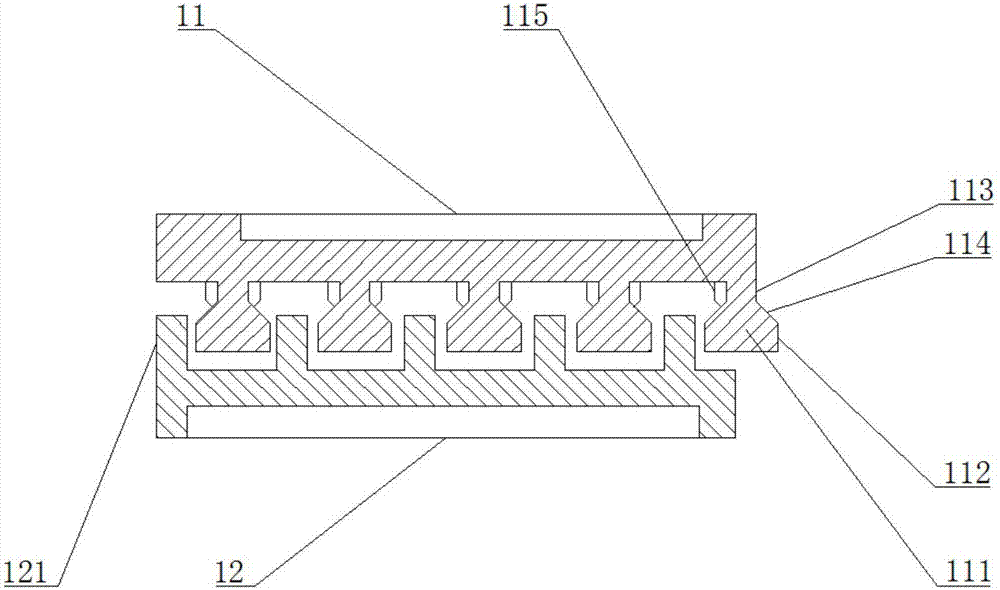

[0032] A new type of jaw crusher, including a frame 1, on which a fixed jaw 2, a movable jaw 3 and an eccentric wheel 4 are arranged, the eccentric wheel 4 is connected with the main motor shaft through a belt, and an eccentric drive shaft is arranged on the eccentric wheel 4 5. The upper end of the movable jaw 3 is connected with the eccentric drive shaft 5, which is hinged on the frame 1, the lower end of the movable jaw 3 is connected with the front end of the toggle plate 6, and the rear end of the toggle plate 6 is connected with the adjustment seat 7, The adjustment seat 7 is connected to the frame 1, the lower end of the movable jaw 3 is connected to the movable rod 8, the movable rod 8 is connected to the frame 1, the fixed jaw 2 is provided with a fixed jaw 9, and the movable jaw 3 is provided with a movable jaw 10. It is characterized in that: the fixed jaw plate 9 is provided with a fixed tooth plate 11, the movable jaw plate 10 is provided with a movable tooth plate...

Embodiment 2

[0035] Based on the first embodiment, the cross-sectional width of the fixed dedendum 112 is greater than twice the cross-sectional width of the fixed dedendum 113 .

[0036] In this embodiment, a chamfer 114 is provided at the connecting portion between the fixed tooth top 112 and the fixed tooth root 113 to prevent crushed ore from being stuck in the connecting portion, thereby reducing the crushing efficiency of the jaw crusher and increasing the difficulty of cleaning.

Embodiment 3

[0038] On the basis of Embodiment 1, a trapezoidal feed bin 13 with a wide top and a narrow bottom is provided between the fixed jaw 3 and the movable jaw 3 .

[0039] In this embodiment, the silo is a trapezoidal structure with a wide top and a narrow bottom, which is crushed step by step to improve the crushing effect of molybdenum ore.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com