Method for preparing gouge mark structure-containing columnar jointing sample for seepage test

A columnar joint and sample preparation technology, which is applied in the preparation of test samples, permeability/surface area analysis, and measurement devices, can solve the problems of consistent filling degree and roughness, poor applicability, and changing seepage paths, and achieve the goal of overcoming Large environmental impact, high economic benefit, high repeatability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

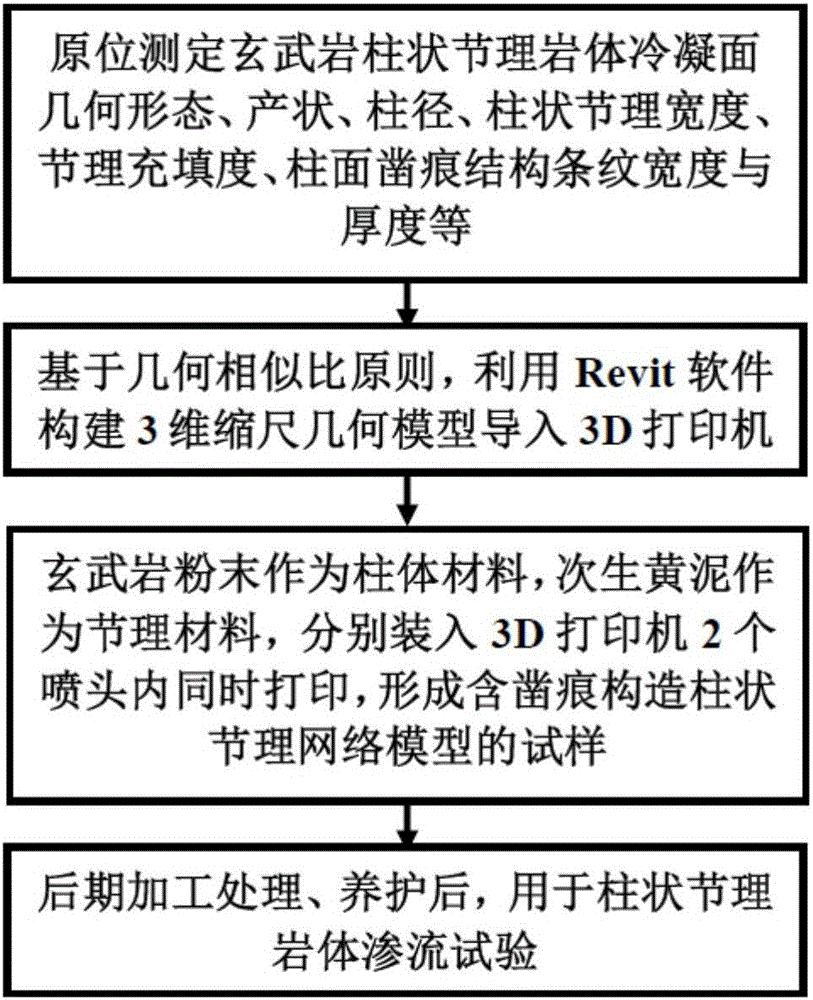

[0031] Such as figure 1 As shown, a method for preparing a columnar joint sample with chisel structure for seepage test, comprising the following steps:

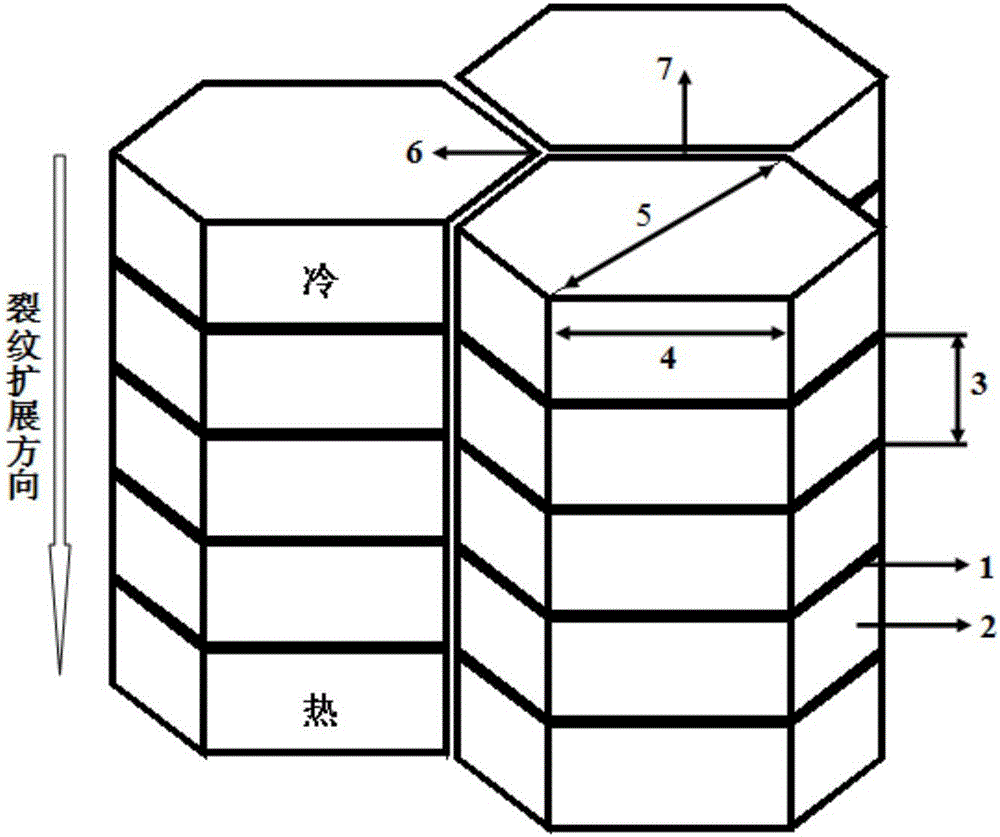

[0032] (1) In-situ measurement of the geometric shape, occurrence, column diameter5, columnar joint width, joint filling degree, columnar chiseling structure stripe width3 and thickness4 of basalt columnar joint rock mass condensation surface;

[0033] The columnar joints, hidden joints and micro-cracks of basalt are filled by secondary yellow mud, and the column surface is distributed with gouging stripes, and the gouging structure is divided into smooth part 2 and rough part 1;

[0034] (2) Based on the principle of similarity ratio, use Revit software to construct a three-dimensional scaled geometric model and import it into a 3D printer;

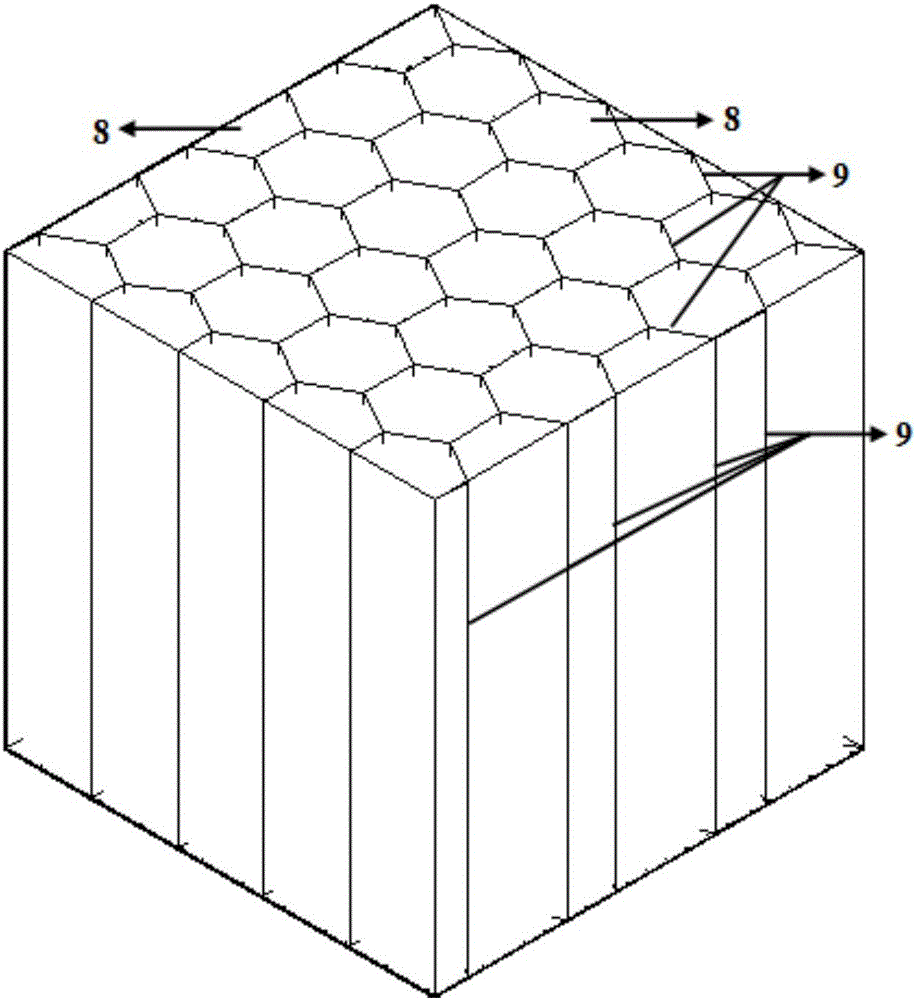

[0035] According to the in-situ geological survey data, the Revit2013 software was used to generate the 3D model of the cylinder and the 3D model of the columnar joint network, and th...

Embodiment

[0045] Taking the preparation of a columnar joint rock mass with chiseling structure in a certain columnar joint area in Zhejiang Province as an example, a preparation method of a columnar joint sample with chiseling structure for seepage tests of the present invention is as follows:

[0046] (1) In-situ measurement of the condensing surface of the basalt columnar joint rock mass. Streak width 3 and thickness 4, etc., based on the principle of geometric similarity ratio, the size of the column 8 is reduced to 1 / 25 of the original, and the 3D models of the column 8 and the joint network 9 are respectively constructed using Revit2013 software;

[0047] (2) Import the model into the MakerBot Replicator 3D printer, use basalt powder as the column 8 material, and secondary yellow mud as the joint network 9 filling material into the two nozzles of the MakerBot Replicator 3D printer, and the two nozzles print at the same time to form a chisel The initial sample of rock mass with trac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com