Flow-control valve for throttling hydraulic pressure medium

A flow control valve, pressure medium technology, applied in the direction of controlling the pressure of the lubricant, the device for absorbing fluid energy of the valve, the pressure lubricant, etc., can solve the problems of insignificant cost factors and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

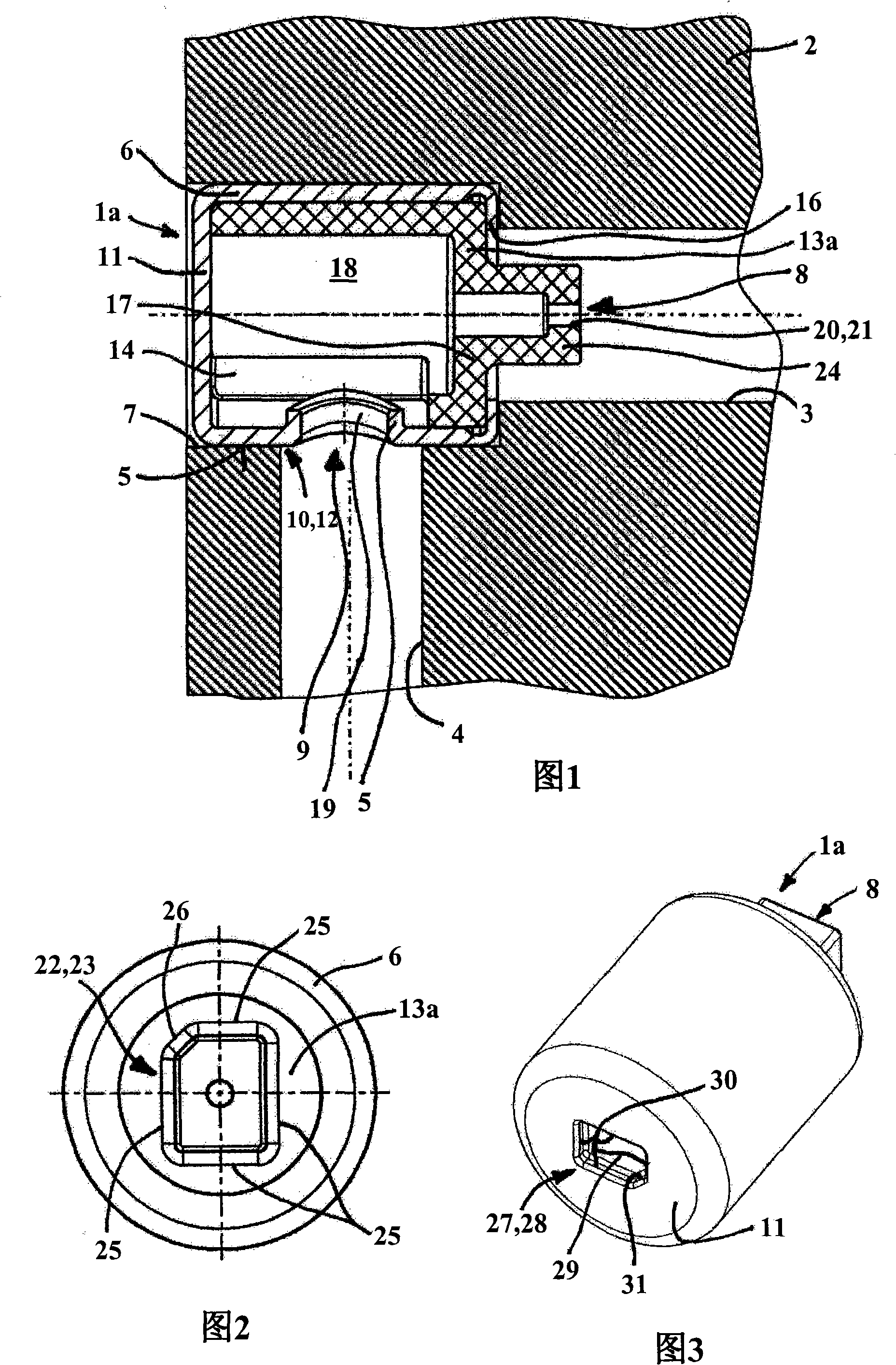

[0018] FIG. 1 shows a first embodiment variant of a flow control valve 1 a according to the invention. The figure shows a machine housing 2 with a pressure medium channel 3 formed in the form of a deep bore, into which a pressure medium channel 4 also opens transversely. The flow control valve 1a is seated in the channel 3 by means of a longitudinal force fit between the cylindrical housing surface 5 of the valve housing 6 and the diametrically widened opening 7 of the pressure medium channel 3 in such a way that: On the side facing away from the opening 7 , a first pressure medium connection 8 is connected to the pressure medium channel 3 , while a second medium connection 9 extending radially through the housing shell surface 5 is connected to the further pressure medium channel 4 . The end 10 of the valve housing 6 facing the opening 7 and adjacent to the second medium connection 9 has a closed housing bottom 11 and is hydraulically sealed to the pressure medium channel 4 b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com