Method for preventing product demolding in megawatt blade die locking process

A technology of megawatts and blades, applied in the field of wind power equipment production, to prevent the mold from demoulding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with specific drawings.

[0013] The method for preventing product stripping during the mold closing process of the megawatt-level blade comprises the following steps:

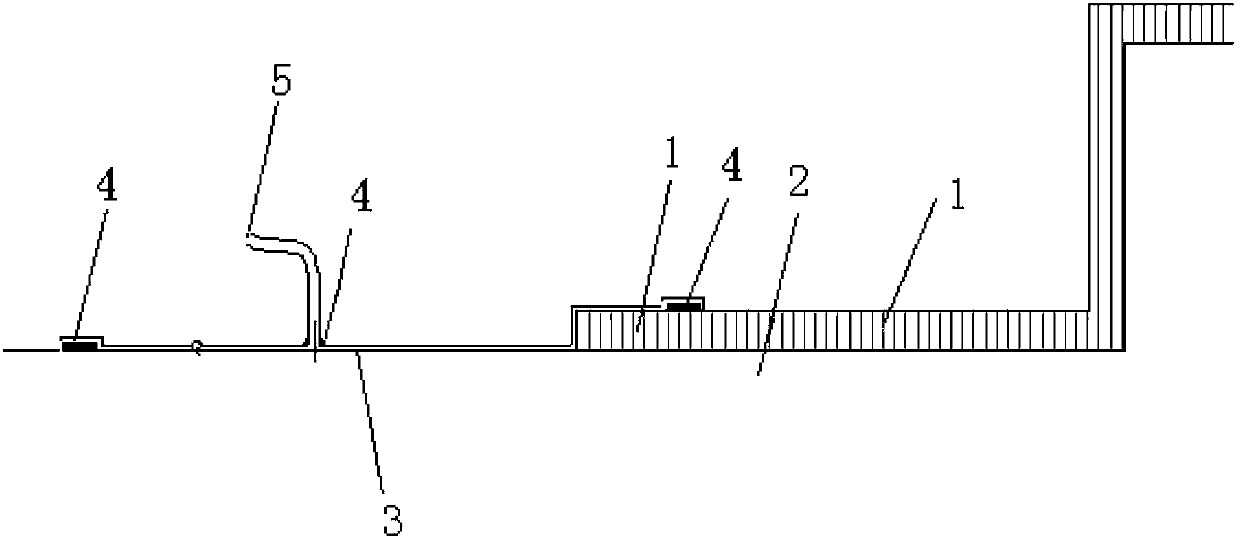

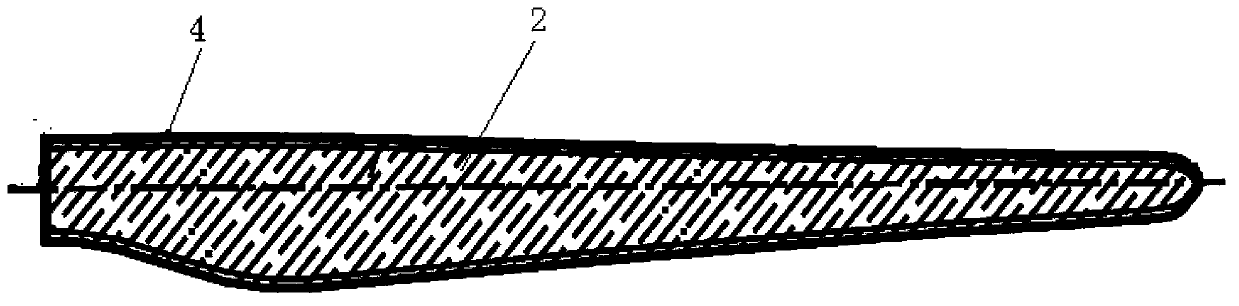

[0014] (1) if figure 1 , figure 2 As shown, the blade product 1 is placed in the mold 2, the edge of the mold 2 is the flange side 3, one side of the flange side 3 is connected with the blade product 1, and a seal is set between the flange side 3 and the blade product 1 Bar 4, a sealing strip 4 is also provided between the other side of the flange side 3 and the mold 2, thereby forming a sealed environment between the mold 2 and the blade product 1, ensuring that the mold 2 and the blade product 1 themselves do not leak;

[0015] (2) Arrange the air extraction pipe 5 on the flange side 3, and the sealing strip 4 is also used to seal the air extraction pipe 5 and the flange side 3; vacuumize through the air extraction pipe 5 to make ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com