PVC extrusion column and molding technology thereof

A molding process and column technology, applied in the field of PVC extrusion column and its molding process, can solve the problems of easy falling off of the coating, non-wear resistance, unsuitable for social development, etc., and achieve the effect of solving serious environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

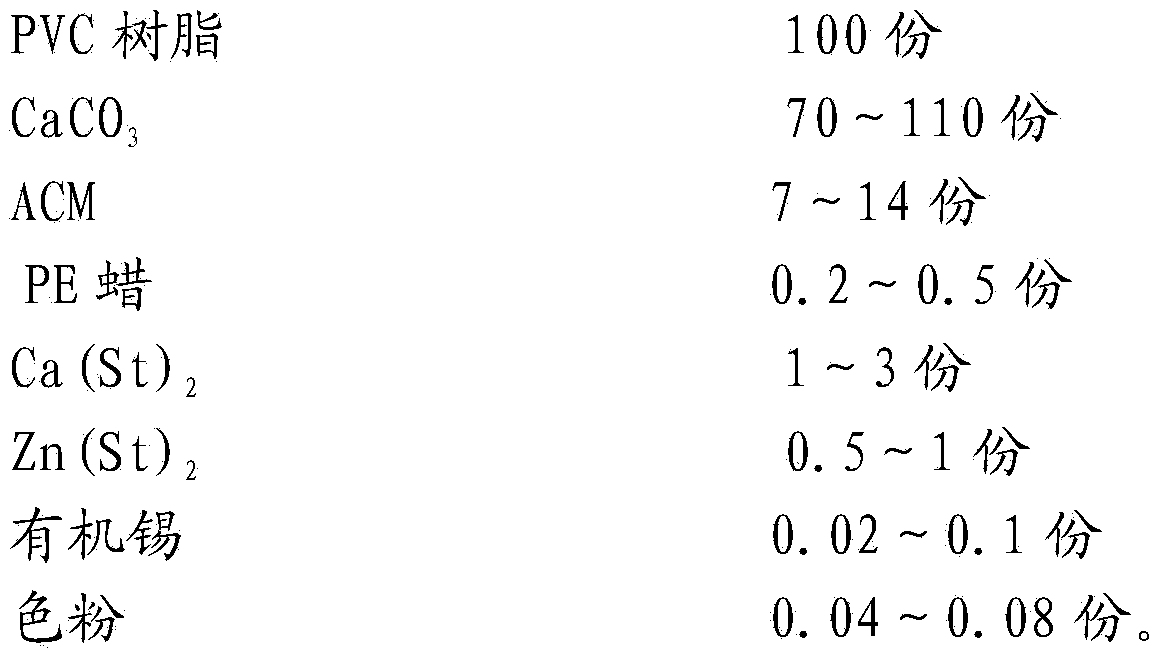

[0013] PVC extrusion column raw materials:

[0014]

[0015]

[0016] PVC extrusion column molding process steps:

[0017] (1) Material mixing: weigh according to the above-mentioned components and their contents, add them to the mixer in batches and mix at high temperature, stop stirring when the temperature reaches 125°C, and then put them into a cooling bucket for stirring. Stop stirring when the temperature drops to 40°C, and put the mixed material into the storage barrel;

[0018] (2) Molding process: use a plastic extruder, the barrel temperature is controlled at 165-180°C, the mold temperature is controlled at 175-190°C, the PVC column profile is vacuum shaped and cooled after extrusion, and then cut according to the predetermined length, that is PVC extruded columns are available.

Embodiment 2

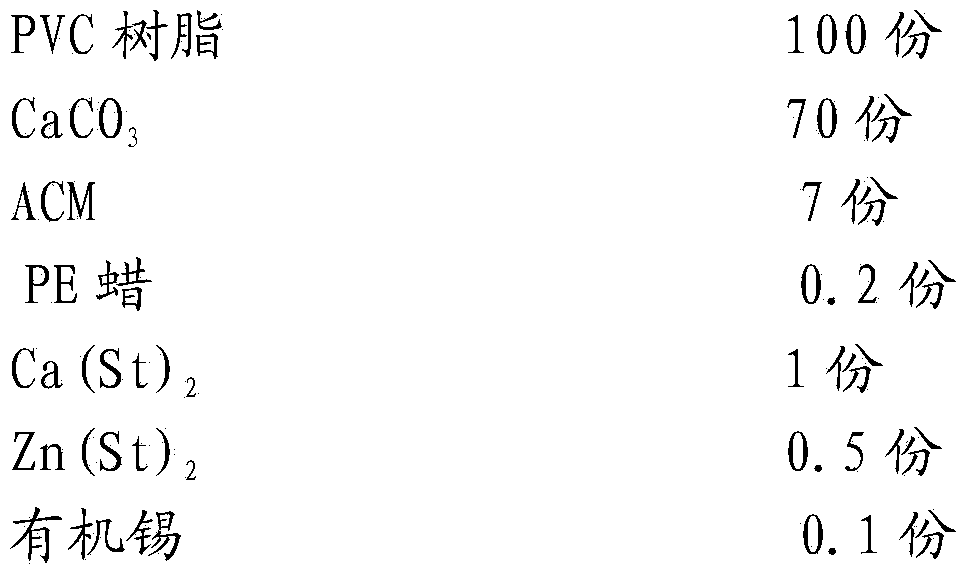

[0020] PVC extrusion column raw materials:

[0021]

[0022] PVC extrusion column molding process steps:

[0023] (1) Material mixing: weigh according to the above-mentioned components and their contents, add them to the mixer in batches and mix at high temperature, stop stirring when the temperature reaches 130°C, and then put them into a cooling bucket for stirring. Stop stirring when the temperature drops to 40°C, and put the mixed material into the storage barrel;

[0024] (2) Molding process: use a plastic extruder, the barrel temperature is controlled at 165-180°C, the mold temperature is controlled at 175-190°C, the PVC column profile is vacuum shaped and cooled after extrusion, and then cut according to the predetermined length, that is PVC extruded columns are available.

Embodiment 3

[0026] PVC extrusion column raw materials:

[0027]

[0028]

[0029] PVC extrusion column molding process steps:

[0030] (1) Material mixing: weigh according to the above-mentioned components and their contents, add them to the mixer in batches and mix at high temperature, stop stirring when the temperature reaches 128°C, and then put them into a cooling bucket for stirring. Stop stirring when the temperature drops to 40°C, and put the mixed material into the storage barrel;

[0031] (2) Molding process: use a plastic extruder, the barrel temperature is controlled at 165-180°C, the mold temperature is controlled at 175-190°C, the PVC column profile is vacuum shaped and cooled after extrusion, and then cut according to the predetermined length, that is PVC extruded columns are available.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com