A kind of hot-rolled narrow strip steel for stamping parts and its preparation method and application

A technology for stamping parts and narrow strip steel is applied in the field of hot-rolled narrow strip steel for stamping parts and its preparation, which can solve the problems of rising production costs and small cold rolling units.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

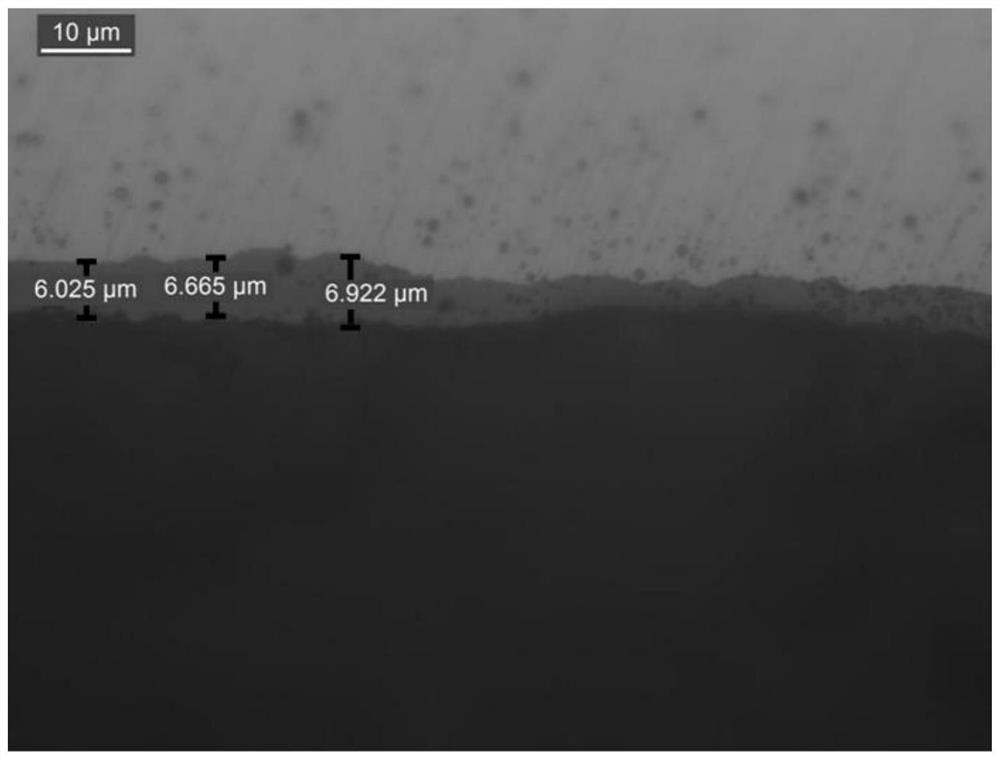

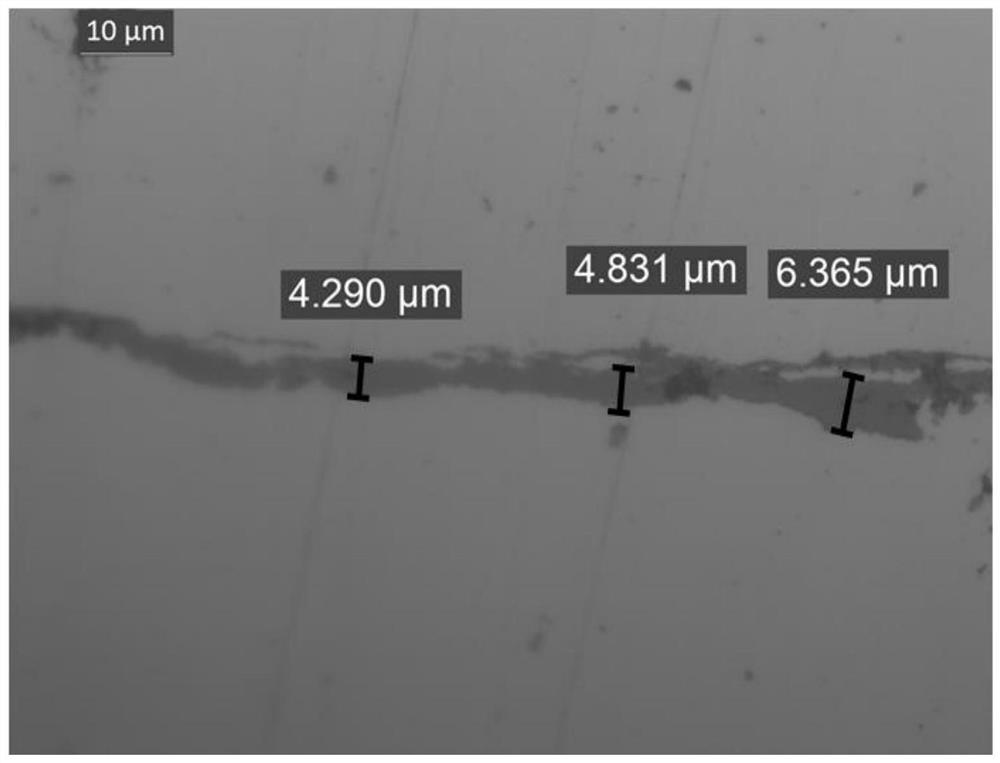

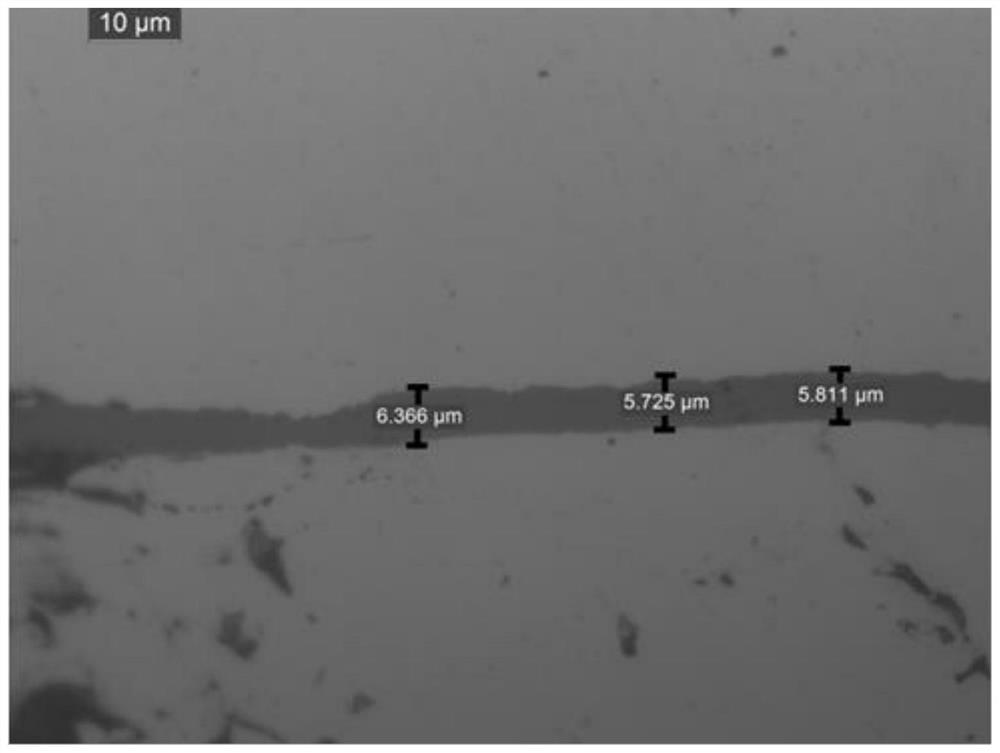

Image

Examples

preparation example Construction

[0028] The invention provides a method for preparing hot-rolled narrow strip steel for stamping parts, comprising the following steps: sequentially heating the cast slab, first dephosphorization, rough rolling, second dephosphorization, finish rolling and coiling to obtain stamping parts Use hot-rolled narrow strip steel;

[0029] The slab includes the following chemical components in mass percentage: C: 0.04-0.08%, Si: 0.08-0.15%, Mn: 0.30-0.40%, P: ≤0.030%, S: ≤0.030%, Cr: ≤ 0.10%, Ni: ≤0.10%, Cu: ≤0.10%, As: ≤0.0080% and the balance iron;

[0030] The heating temperature is 1280-1300°C, and the heating time is 130-140min;

[0031] The inlet temperature of the rough rolling is 1250-1270°C;

[0032] An intermediate billet is obtained after the rough rolling, and the thickness of the intermediate billet is 26-28 mm;

[0033] The coiling temperature is 580-610°C;

[0034] The finish rolling is 9-pass rolling, and the roll diameters of the work rolls decrease successively fr...

Embodiment 1

[0049] Metal raw materials are smelted into a rectangular billet with a section of 165×280 mm. The mass percentage of the chemical composition of the rectangular billet is: C: 0.04%, Si: 0.10%, Mn: 0.32%, P: 0.015%, S: 0.017%, Cr : 0.02%, Ni: 0.01%, Cu: 0.01%, and the rest is iron.

[0050] The heating temperature in the soaking section is 1282°C, the heating time is 135min, the descaling pressure of the first pass is 17.56MPa, the entrance temperature of rough rolling is 1252°C, the exit thickness of the first pass of rough rolling is 126.5mm, the exit thickness of the second pass is 93.6mm, The exit thickness of the third pass is 62.7mm, the exit thickness of the fourth pass is 41.2mm, the exit thickness of the fifth pass is 26.3mm, and the rough rolling finish rolling temperature is 1208°C. The descaling pressure of the second pass is 18.35MPa, the finish rolling inlet temperature is 1168°C, the work roll diameter of the first pass of finish rolling is 512.5mm, the work rol...

Embodiment 2

[0053] Metal raw materials are smelted into a rectangular billet with a section of 150×330mm. The mass percentage of the chemical composition of the rectangular billet is: C: 0.08%, Si: 0.15%, Mn: 0.30%, P: 0.018%, S: 0.020%, Cr : 0.01%, Ni: 0.03%, Cu: 0.03%, and the rest is iron.

[0054] The heating temperature in the soaking section is 1295°C, the heating time is 140min, the descaling pressure of the first pass is 19.53MPa, the rough rolling inlet temperature is 1268°C, the exit thickness of the first rough rolling pass is 120.2mm, the exit thickness of the second pass is 90.1mm, The exit thickness of the third pass is 61.0mm, the exit thickness of the fourth pass is 40.6mm, the exit thickness of the fifth pass is 26.1mm, and the rough rolling finish rolling temperature is 1217°C. The descaling pressure of the second pass is 18.76MPa, the finish rolling inlet temperature is 1185°C, the work roll diameter of the first pass of finish rolling is 500.6mm, the work roll diameter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com