A Five-Stand Confined Mandrel Continuous Rolling Mill Conducive to Reducing Roll and Mandrel Consumption

A technology of limited mandrel and five stands, which is applied in the direction of metal rolling, can solve the problems of large mandrel reserves, large consumption of rolls and mandrels, etc., to reduce steel consumption per ton, reduce rolling load, and save The effect of cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

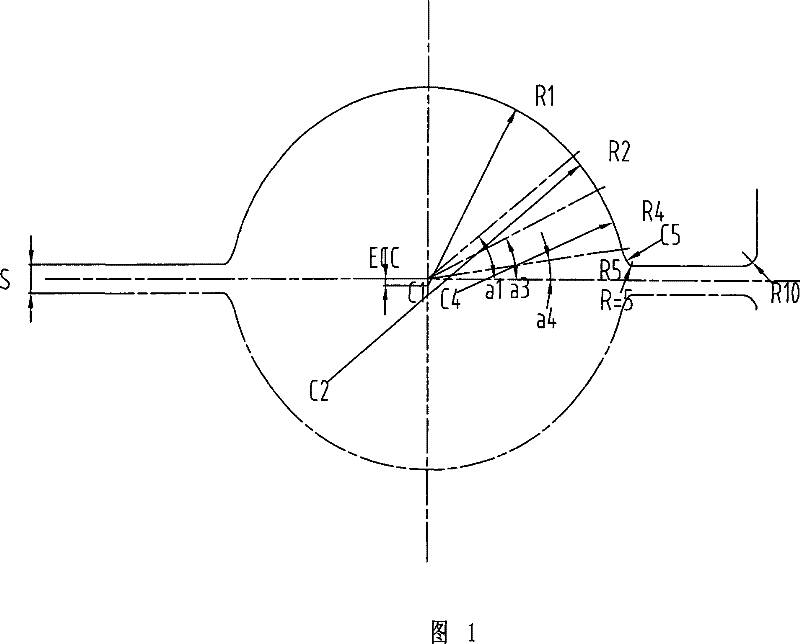

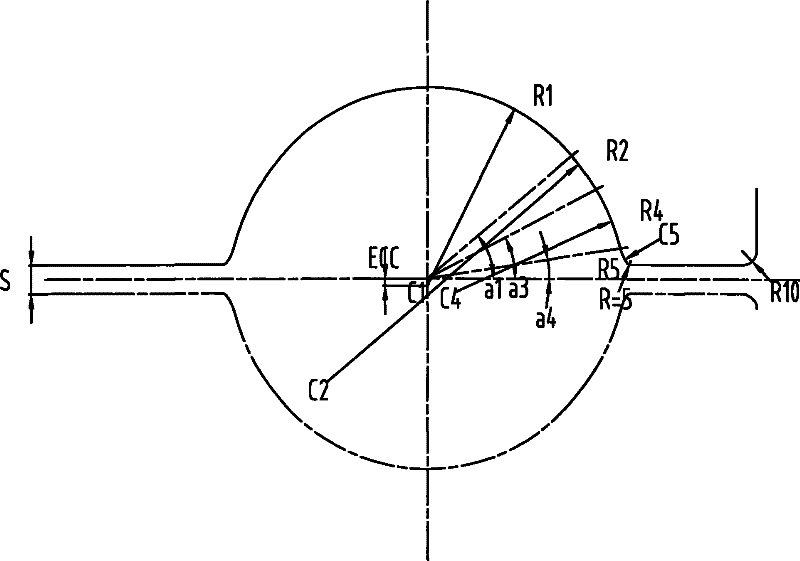

[0007] See figure 1 , the present invention selects an ellipse-round pass system, and the pass is composed of groove bottom arc R1, first escape arc R2, second escape arc R4, connecting arc R5 and corresponding roll gap S; a transition is set up at the connecting arc and roll gap Rounded corners; where a, the groove bottom arc is tangent to the first escape arc; b, the first escape arc is tangent to the groove bottom arc and the second escape arc; c, the second escape arc is inscribed to the first escape arc, and The connection arc is circumscribed; d. The connection arc is the common tangent arc between the second departure arc and the pass center line; For elliptical pass, the eccentric distance ECC of the next frame is half of that of the previous frame, the eccentric distance ECC of the first frame is set to 0.645 times of the thinnest wall thickness of the steel pipe rolled by the designed pass, the second frame, the third frame The connection angle α4 of the rack is set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com