Fuel assembly, bottom device thereof, and lower tube seat applied to bottom device

A fuel assembly and bottom device technology, which is applied in the field of reactor engineering, can solve problems such as insufficient tube sockets under the fuel assembly, and achieve the effects of lowering temperature, enhancing safety, and enhancing heat transfer effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

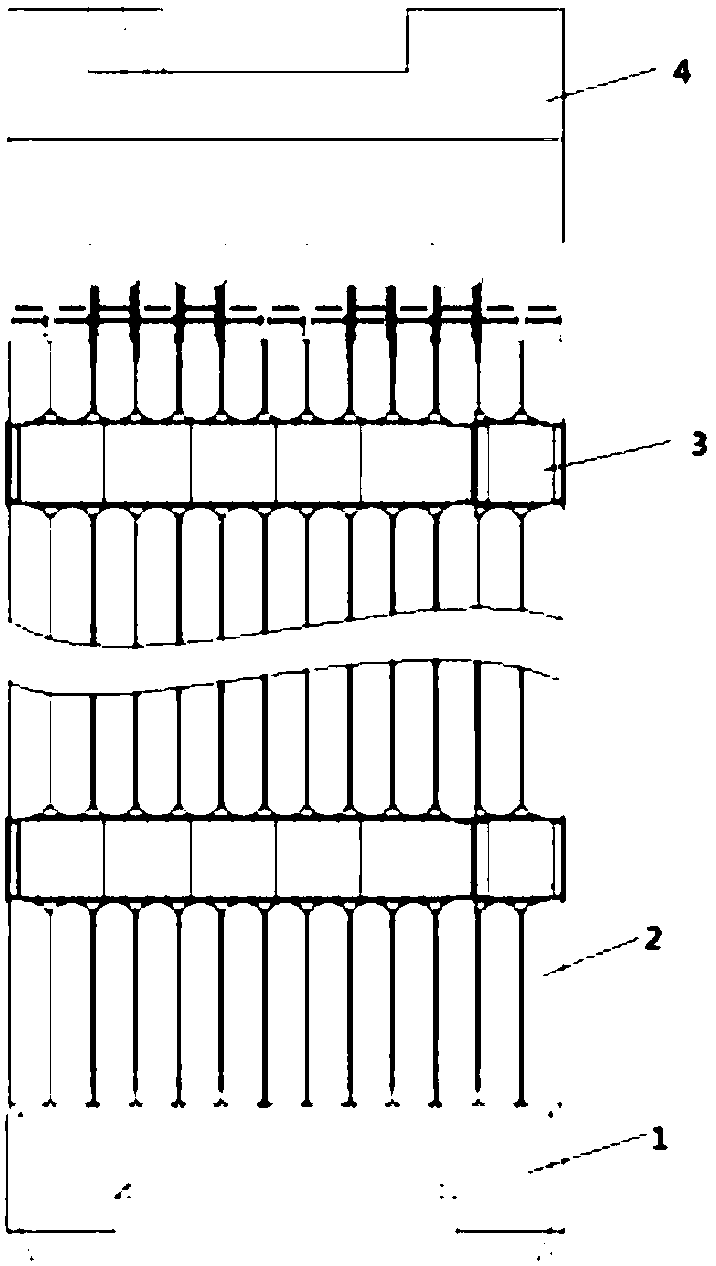

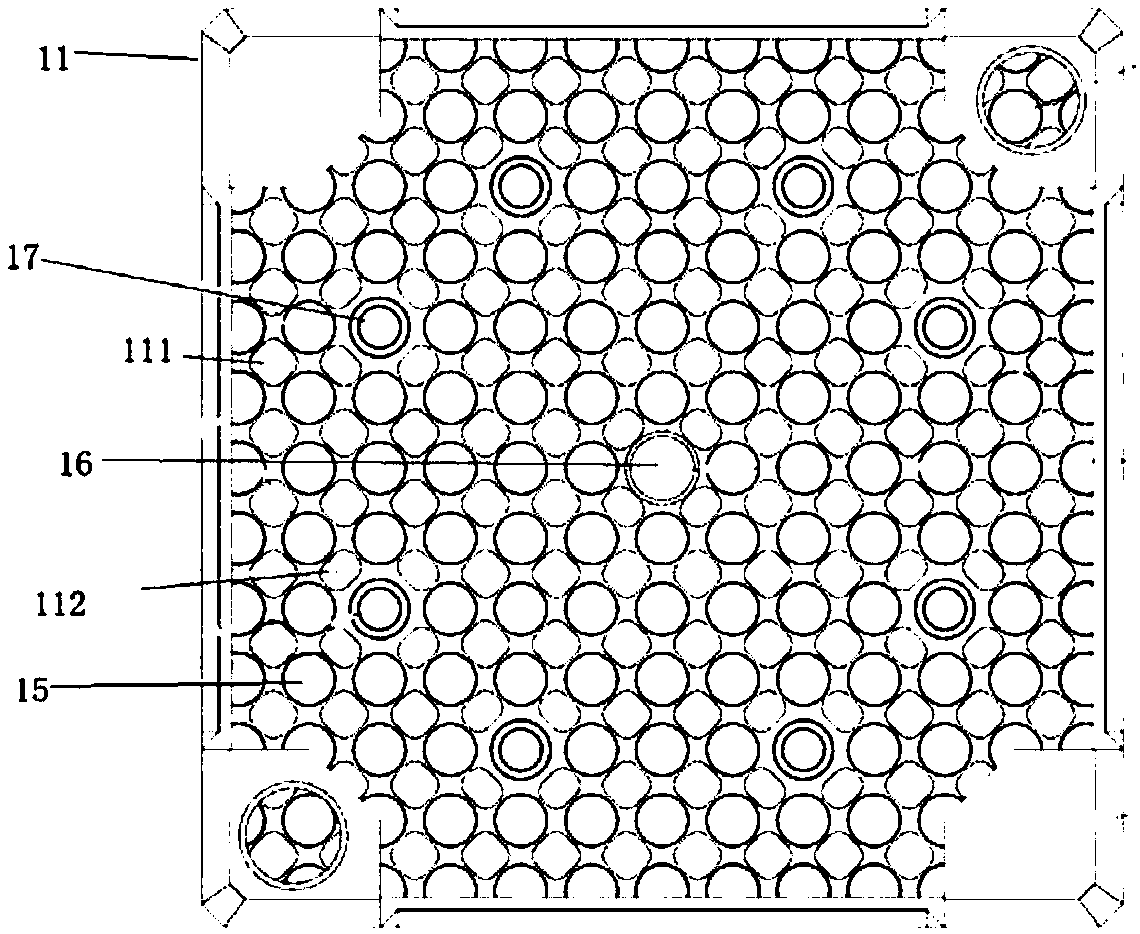

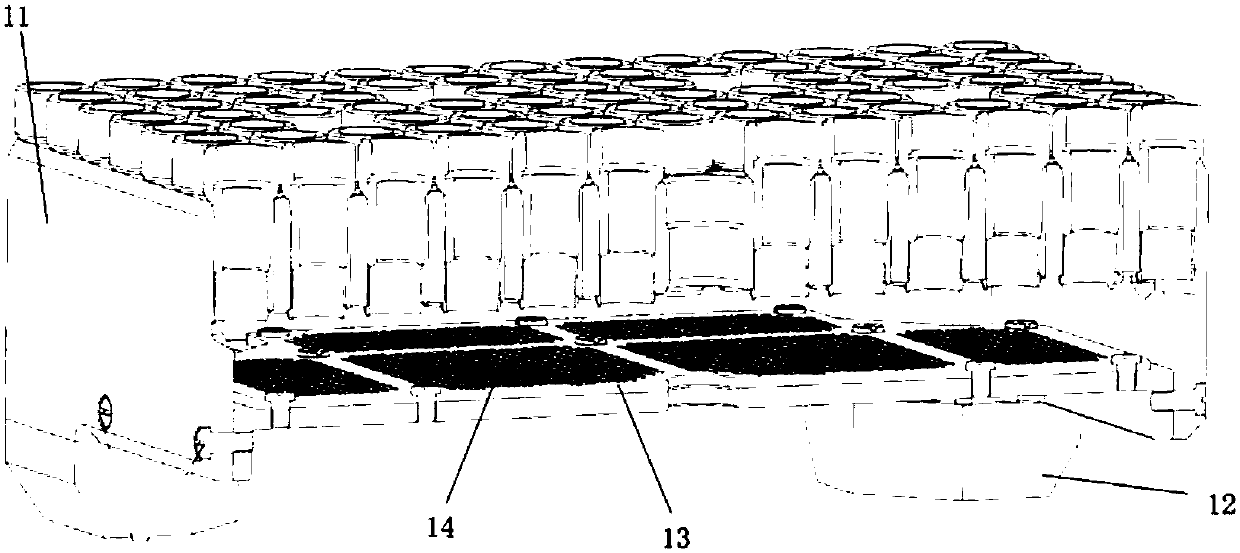

[0041] like Figures 1 to 5 As shown, a lower nozzle base of a fuel assembly includes: a lower nozzle frame body 11, a leg 12 arranged at the lower part of the lower nozzle frame body 11, and several vertically and horizontally arranged in parallel on the upper end surface of the lower nozzle frame body 11 The equal diameter through hole 15, the neutron measuring tube hole 16 and the lower end plug hole 17 of the guide tube; it is characterized in that the equal diameter through hole 15 is circular.

[0042] The maximum difference between the inner diameter and the outer diameter of the equal-diameter through hole 15 ranges from 0.05 to 0.4 mm.

[0043] A rectangular mainstream water hole A111 is provided at the center of the rectangle surrounded by the four adjacent equal-diameter through holes 15; several mainstream water holes B112 are provided around the plug hole 17 at the lower end of each guide tube and the neutron measuring tube hole 16.

[0044] The main water hole B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com