Friction plate carrier, dual clutch assembly and method for manufacturing friction plates

A dual-clutch device and friction plate technology, which is applied in the direction of friction clutches, friction linings, clutches, etc., can solve problems such as high cost, achieve low cost, reduce leftover materials, and save costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

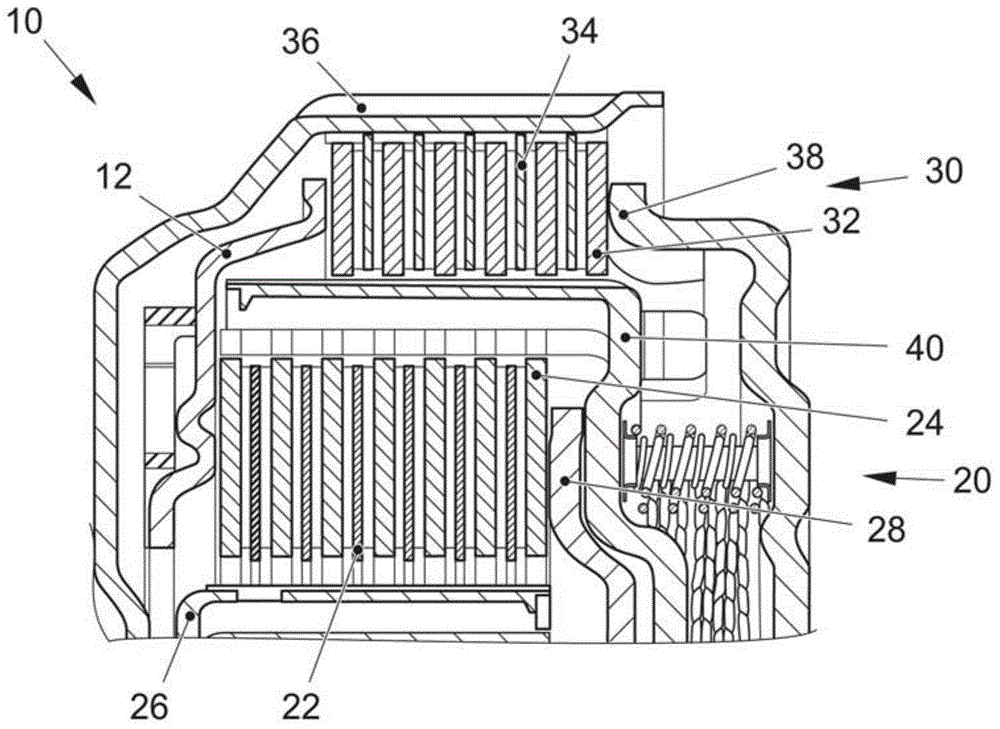

[0035] figure 1 A partial sectional view of a dual clutch arrangement 10 according to the invention is shown. This dual clutch arrangement comprises two clutches which can be operated independently, namely a radially inner clutch 20 and a radially outer clutch 30 .

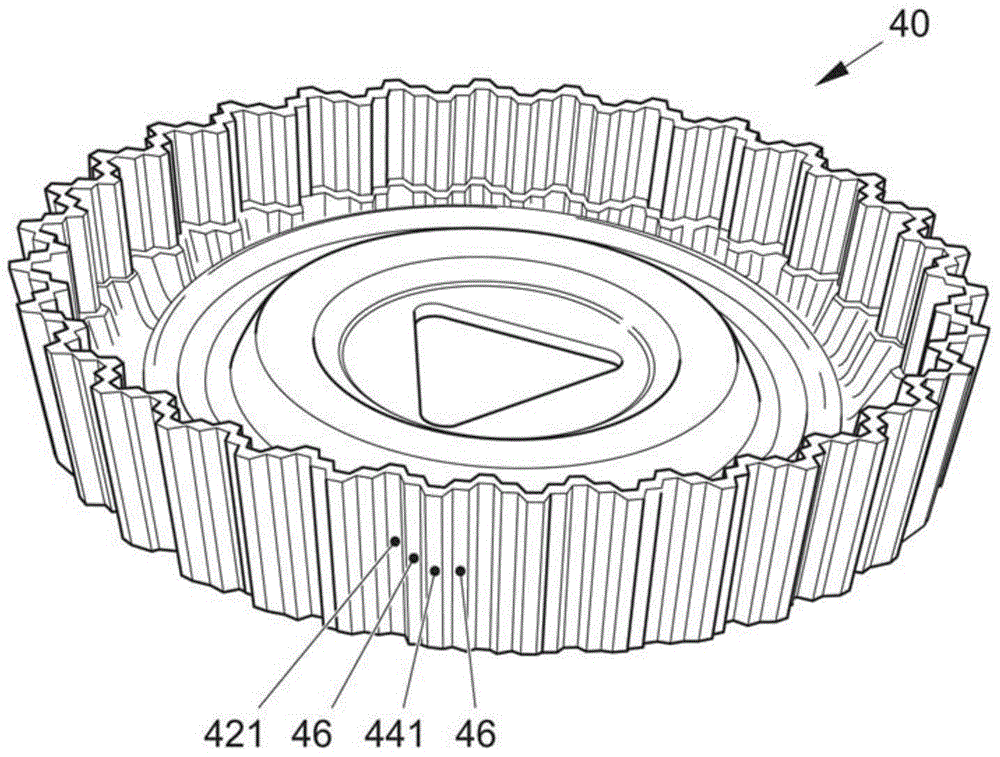

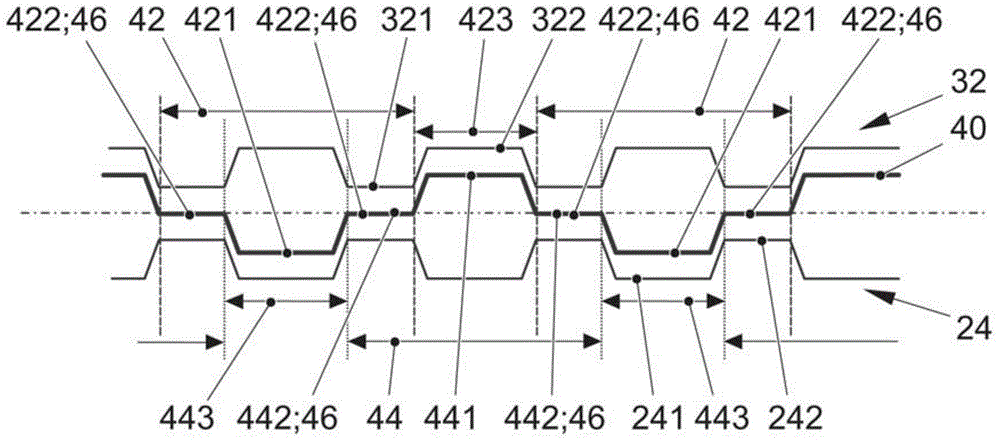

[0036] The radially inner clutch 20 includes a set of inner friction plates 22 arranged axially alternately with a set of outer friction plates 24 . The inner disk 22 is axially displaceably mounted by means of its internal toothing in the toothing of a corresponding inner disk carrier 26 . The outer disk 24 is axially displaceably mounted by means of its outer toothing on the inner toothing of an intermediate disk carrier 40 , which will be explained in more detail below, and which serves as the outer friction of the radially inner clutch 20 . sheet holder. The disk package consisting of the inner disk 22 and the outer disk 24 can be pressed against the intermediate support plate 50 by means of a pressure plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com