High-sulfur steel rolling process

A technology with high sulfur content and craftsmanship, applied in metal rolling, manufacturing tools, metal rolling, etc., can solve problems such as slippage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

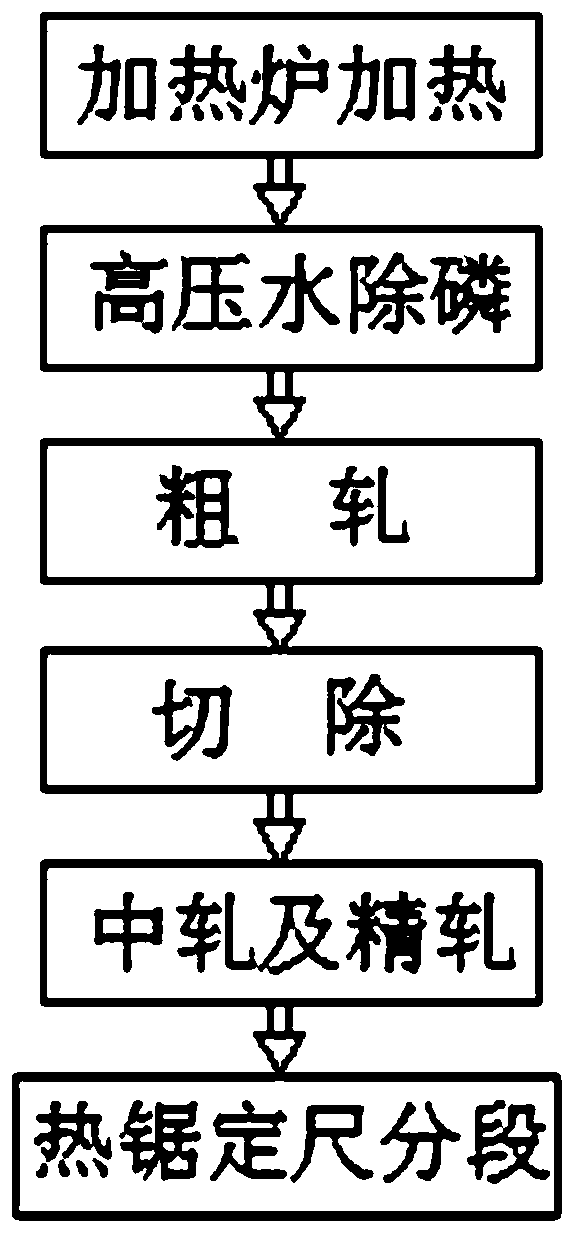

[0020] See figure 1 , taking the stability and production efficiency of the rolling process of 20 high-sulfur steels as an example, it specifically includes the following steps:

[0021] Step 1: Select 4 steel grades of 1215YG high-sulfur steel continuous casting billets (w(S)=0.30%~0.40%), and 4 steel grades of 44SMn28 high-sulfur steel continuous casting billets (w(S) )=0.23%~0.33%), 4 SAE1215 high-sulfur steel continuous casting slabs (w(S)=0.26%~0.34%), 4 SAE1144 high-sulfur steel continuous casting slabs (w(S)=0.24% ~0.30%), 4 pieces of 1215CW high-sulfur steel continuous casting slabs (w(S)=0.26%~0.40%), the sections of 20 high-sulfur steel continuous casting slabs are all 320mm×425mm, check the surface condition of the continuous casting slabs , to ensure that the surface of the blank meets the appearance quality requirements;

[0022] Step 2: Divide 20 high-sulfur continuous casting slabs with good surface quality into two groups (Group 1: 2 pieces of 1215YG, 2 piece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com