A laminar flow cooling process for hot-rolled strip steel

A laminar flow cooling and hot-rolled strip technology, applied in metal rolling, manufacturing tools, metal rolling, etc., can solve the problems affecting the uniformity of performance and plate shape, ineffective purging, coiler biting and slipping, etc. , to achieve the effect of product performance control, ingenious design, and improvement of toughness index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Embodiment 1: see figure 1 — Figure 9 , a hot-rolled steel strip laminar cooling process, the method steps are as follows,

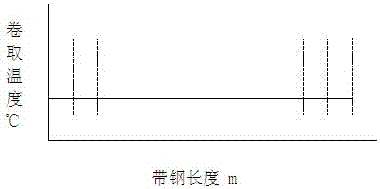

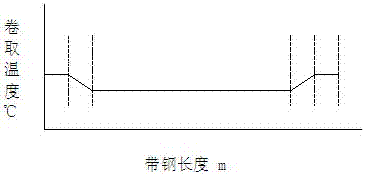

[0048] (1) Optimize a linear laminar flow temperature curve into a dynamically variable five-section control curve like a "boat shape", as follows: the first section is the hot head section, the length L1 is 10-100m, the second section is the hot section The head transition section, the length L2 is 5-20 m, the third section is the middle section L3 of the strip steel, the fourth section tail transition section, the length L4 is 5-20m, the fifth section is the hot tail section, the length L5 is 10- 100m; the cooling temperature of the five sections is controlled respectively: the middle section is equal to the target coiling temperature, the head section is the target coiling temperature ±0-50°C, the tail section is the target coiling temperature ±0-50°C, the hot head transition section and The thermal tail transition section transitions unifor...

Embodiment 2

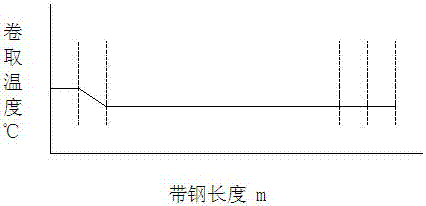

[0081] Embodiment 2: the application of cold tail process

[0082] To produce pipeline steel X52 with a thickness of 12.55mm, the quality design requires a coiling temperature of 550±20°C. In the actual production process, due to the thicker finished product thickness of 12.55mm, the slower rolling speed of 130mpm, and the shorter finished product length of 120-160m, the CTC model is not capable of controlling the CT of the tail of the strip, and the coiling temperature suddenly rises at the tail of 50-60m. To the tail 20-30m coiling temperature rises to 590-610 ℃, such as Figure 11 , causing the X52 coiling temperature control to exceed the standard, and the mechanical properties and anti-HIC performance are inconsistent. The technical scheme adopted is as follows:

[0083] 1. According to the analysis, there are fluctuations in the coiling temperature, which affect the performance of the steel coil. The comparison found that the coil temperature of the first half was bas...

Embodiment 3

[0092] Embodiment 3: the application of thermal tail technology

[0093] When producing H-Q195 with a thickness of 2.3mm, the laminar flow water at the tail cannot be cleaned smoothly, resulting in uneven cooling and poor plate shape. On-site tracking confirmed that due to the high velocity of the tail and the large amount of laminar water, normal purge cannot clean the laminar water on the surface. According to the analysis, it can be improved through the hot tail process. According to the field test tracking, L5=40 meters is determined according to the distance from the last stand of the finishing rolling to the first set of laminar water opening. Under the worst conditions, an increase of 30°C can basically ensure that the purge is clean. It is determined that the length of L3 is 10 meters, the length of L4 is 40 meters, and the effect is good when T2 is 40°C. After the implementation, the water accumulation at the end of the strip steel has been controlled, and the user ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com