Preparation method for improving ring pressure strength of low-gram-weight T paper board

A technology of ring crush strength and low gram weight, applied in the field of T cardboard, can solve the problems of lack of market competitiveness of products, increase of waste water pollution load, rising production cost, etc., to improve starch sizing effect, improve ring crush strength, improve The effect of strength indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

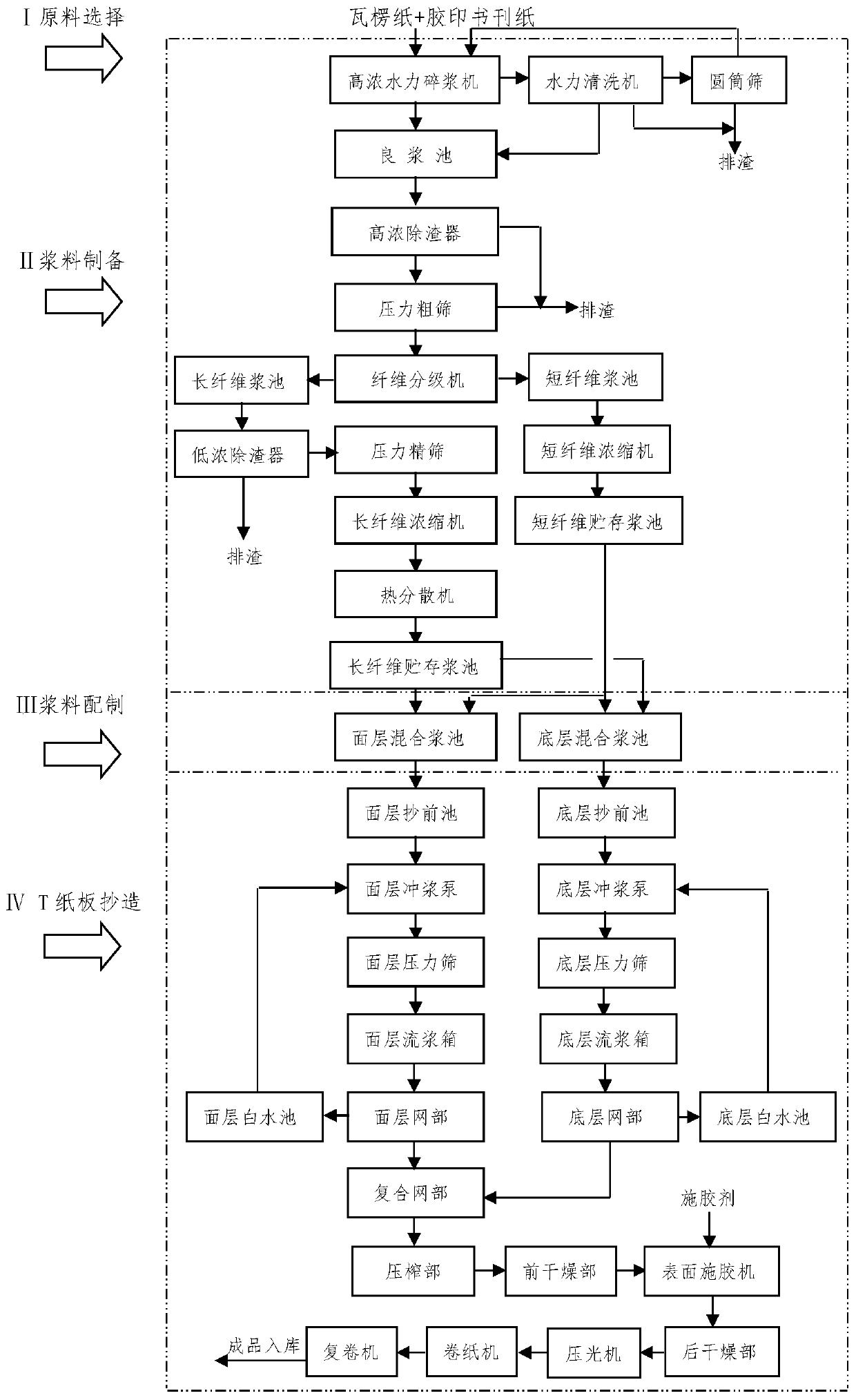

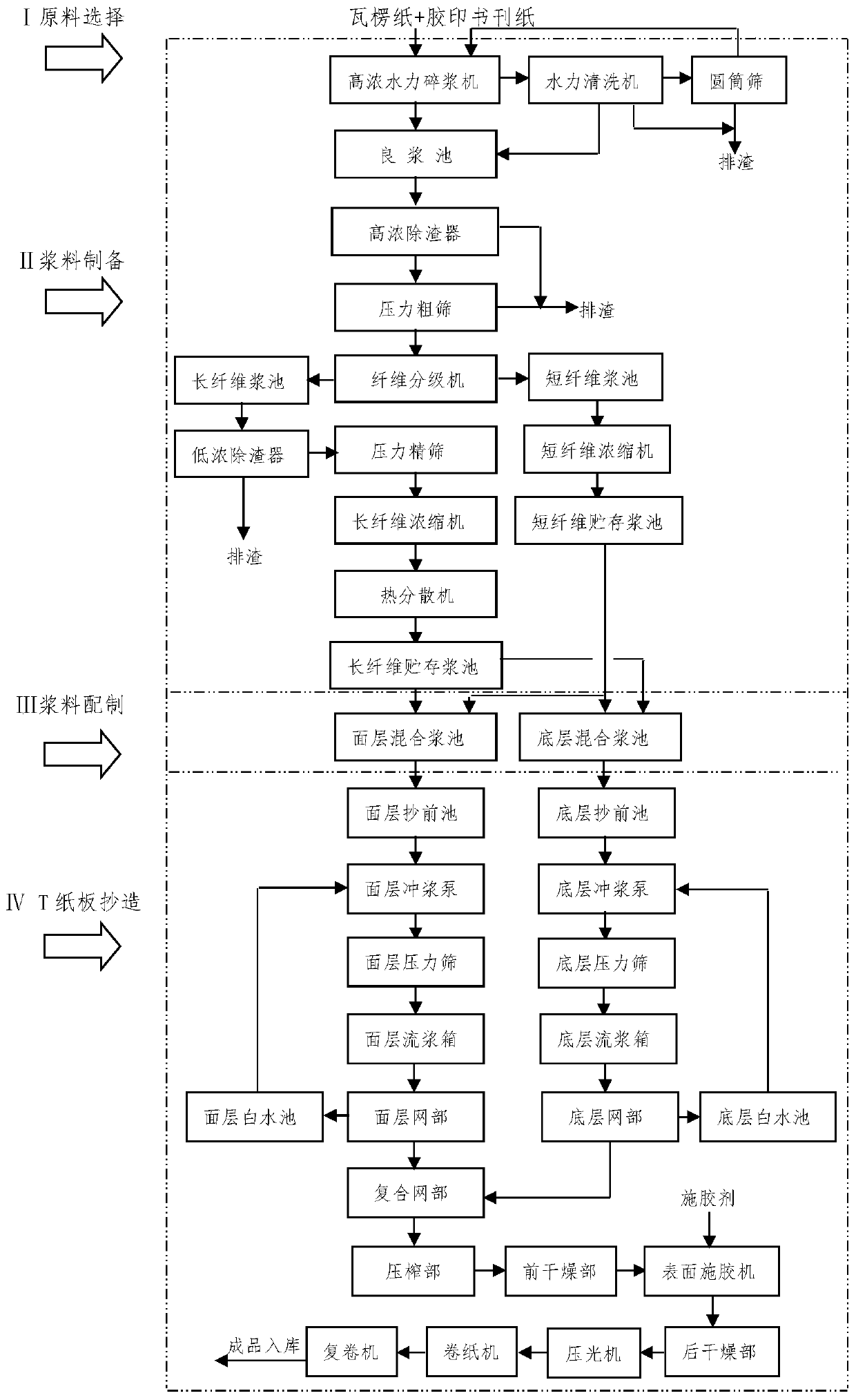

[0023] The preparation method of the present invention comprises the following steps:

[0024] Step 1, raw material selection: use corrugated paper and offset printing book paper as raw materials;

[0025] Step 2, slurry preparation: After weighing the corrugated paper and offset printing book paper in proportion, send them to a high-consistency hydraulic pulper, add water to dilute to a concentration of 8% to 12%, and disintegrate for 20min to 25min at a temperature of 60°C to 70°C, dilute the disintegrated fine pulp with water to a concentration of 3% to 5% and put it into the fine pulp tank. After the coarse pulp is removed by a hydraulic cleaning machine and a cylindrical sieve, it is sent to the good pulp tank for storage. ;After stirring the slurry in the good pulp tank, pump it to the high-concentration slag remover and coarse screen to remove light and heavy impurities of fiber, and classify the slurry into two types: long fiber pulp and short fiber pulp through the fi...

Embodiment 1

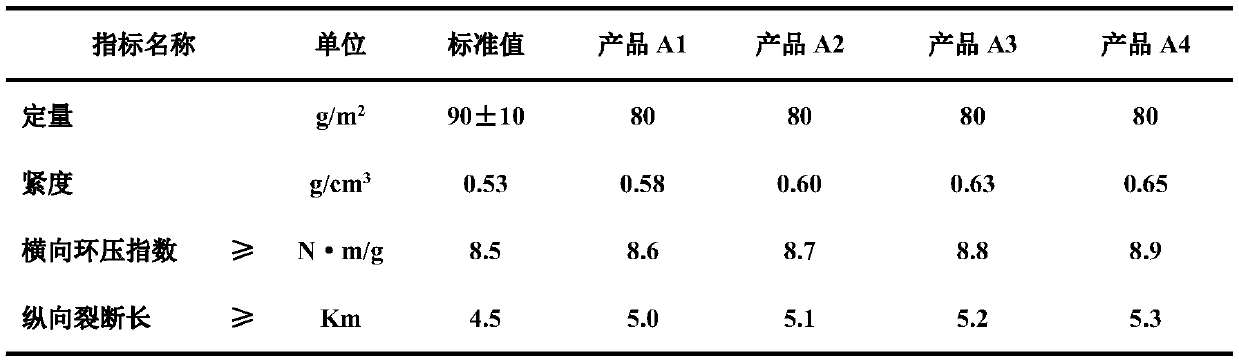

[0030] Embodiment 1, quantification is 80g / m 2 The product:

[0031] The first product A1, the raw material is corrugated paper and offset printing book paper, the ratio is 70%: 30%, after mixing, long fiber and short fiber pulp are obtained, and the ratio is 70%: 30%, and the surface sizing agent is tapioca starch 6%. , starch converting enzyme 0.1%;

[0032] The second product A2, the raw material is corrugated paper and offset printing book paper, the ratio is 75%: 25%, long fiber and short fiber pulp are obtained after mixing, the ratio is 70%: 30%, and the surface sizing agent tapioca starch is 8% , starch converting enzyme 0.2%;

[0033] The third product A3, the raw material is corrugated paper and offset printing book paper, the ratio is 78%: 22%, after mixing, long fiber and short fiber pulp are obtained, and the ratio is 80%: 20%, and the surface sizing agent tapioca starch is 6% , starch converting enzyme 0.1%;

[0034] The fourth product A4, the raw material is...

Embodiment 2

[0038] Embodiment 2, quantification is 90g / m 2 Products B1, B2, B3 and B4:

[0039] The first product B1, the raw material is corrugated paper and offset printing book paper, the ratio is 70%: 30%, after mixing, long fiber and short fiber pulp are obtained, and the ratio is 70%: 30%, and the surface sizing agent is 6% tapioca starch , starch converting enzyme 0.1%;

[0040] The second product B2, the raw material is corrugated paper and offset printing book paper, the ratio is 75%: 25%, after mixing, long fiber and short fiber pulp are obtained, and the ratio is 70%: 30%, and the surface sizing agent tapioca starch is 8% , starch converting enzyme 0.2%;

[0041] The third product B3, the raw material is corrugated paper and offset printing book paper, the ratio is 78%: 22%, after mixing, long fiber and short fiber pulp are obtained, and the ratio is 80%: 20%, and the surface sizing agent tapioca starch is 6% , starch converting enzyme 0.1%;

[0042] The fourth product B4, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com