Converter oxygen consumption prediction method based on grey prediction and neural network combined model

A neural network and gray model technology, applied in the field of converter oxygen prediction in iron and steel enterprises, can solve problems such as converter oxygen consumption, achieve the effects of improving oxygen utilization, accelerating convergence speed, and reducing poor stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

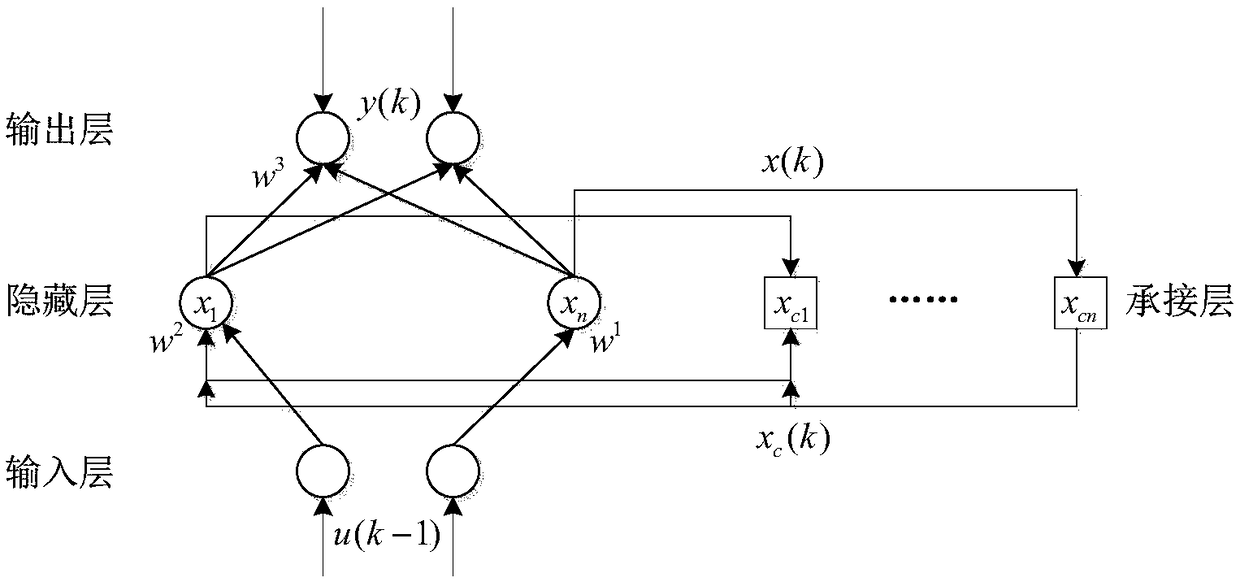

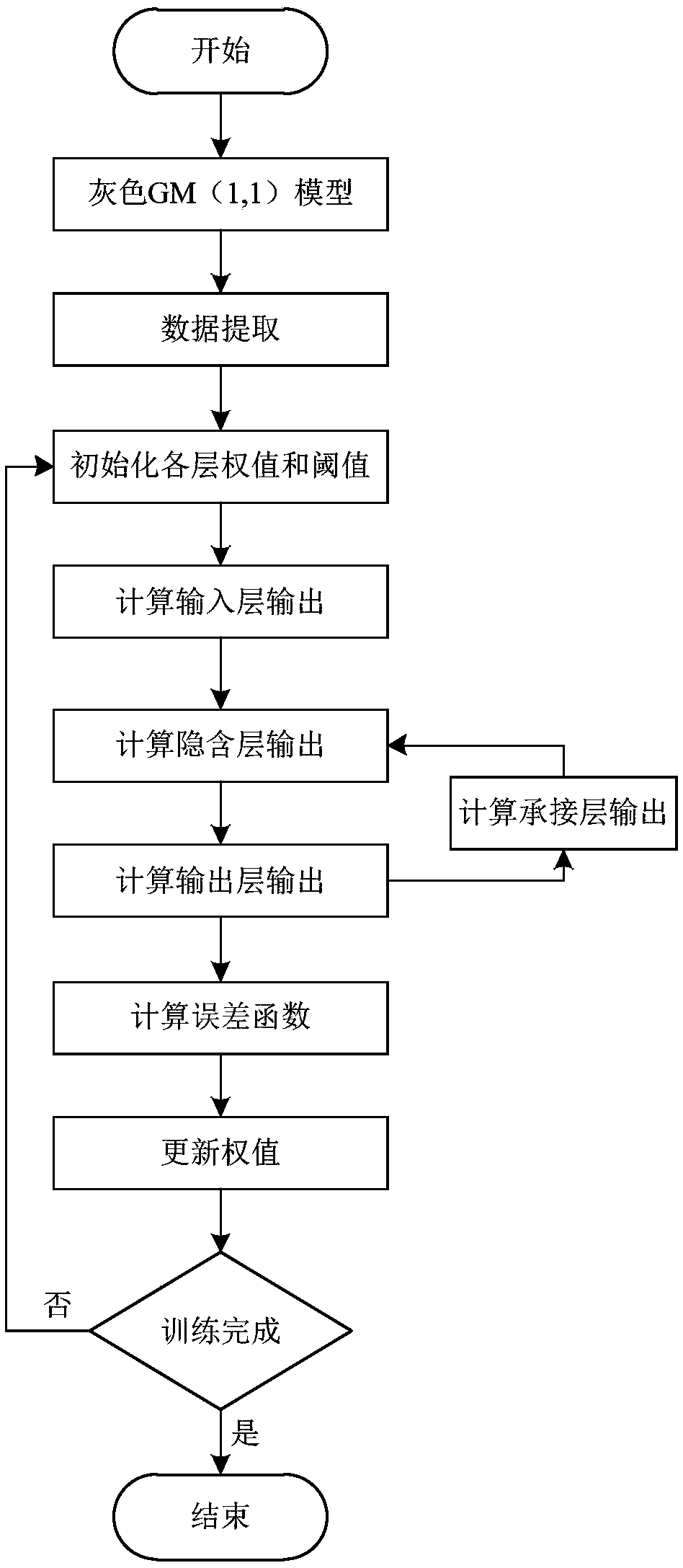

Method used

Image

Examples

Embodiment Construction

[0057] An example is given below, and the specific implementation manner of the present invention is further described in detail.

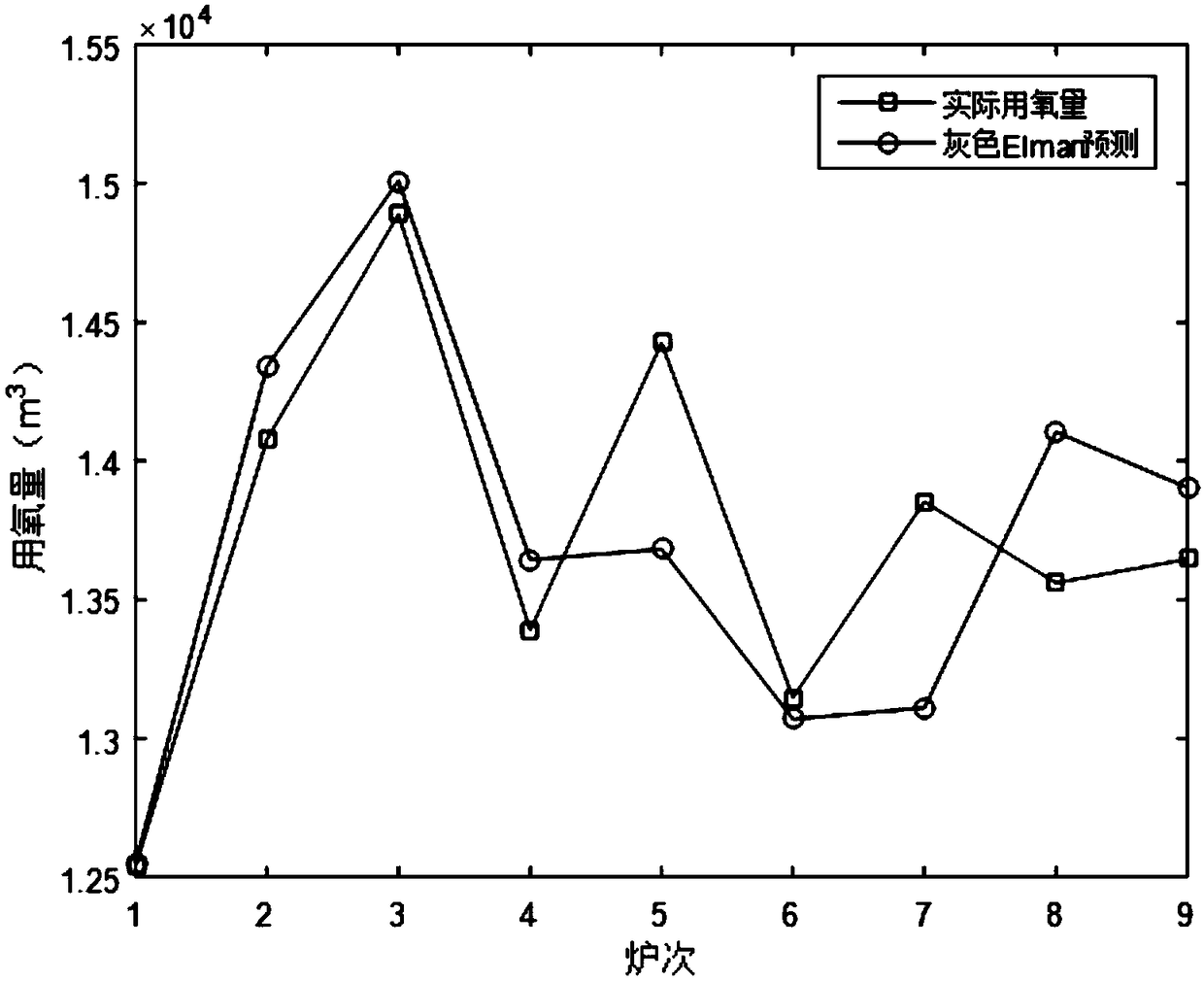

[0058] A United Iron and Steel Co., Ltd. adopts the "one tank to the bottom" operation method. According to its converter process characteristics, operating experience and correlation analysis, the input variables are determined to be nine influencing factors. Due to the adoption of stirring desulfurization, the influence of S elements on the oxygen consumption It is small, and it is not used as an input influencing factor. The specific input variables are molten iron amount, scrap steel amount, molten iron temperature, initial C%, silicon content, manganese content, phosphorus content, end point C% and tapping temperature. The input factors interact with each other, and the data has many dimensions. The input variables have a direct impact on the accuracy of the oxygen consumption prediction model. Due to the poor stability of some testing equipm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com