Production technology of machine-made semi-coke barbecue charcoal with small particle size

A production process and small particle size technology, applied in the field of barbecue charcoal, which can solve the problems of carbon rod wet strength, cold strength decrease, particle specific surface area reduction, and excessive carbon particle size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

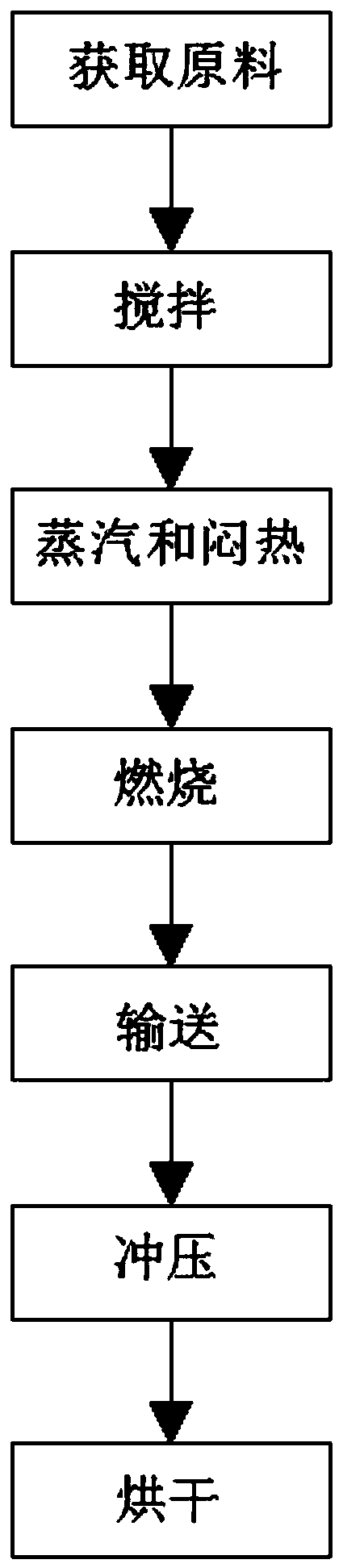

[0027] Please refer to figure 1 ,in, figure 1 It is a structural schematic diagram of a preferred embodiment of the production process of the small particle size machine-made blue charcoal barbecue charcoal provided by the present invention. The production process of small particle size mechanism blue charcoal barbecue charcoal includes:

[0028] S1. Obtaining raw materials: put coal into the interior of the vertical and bipolar crusher, and sieve through the secondary crushing of the vertical and bipolar crusher to obtain the raw materials required by the particle size composition. Here, the raw material is semi-coke. Semi-coke is fired from the high-quality Jurassic clean coal abundant in Shenfu Coalfield. As a new type of carbon material, it has high fixed carbon, high specific resistance, high chemical activity, low ash content, low aluminum, Low sulfur and low phosphorus characteristics, to gradually replace metallurgical coke and widely used in the production of calciu...

no. 2 example

[0048] Based on the production process suitable for small particle size machine-made blue charcoal barbecue charcoal provided in the first embodiment of the present application, the second embodiment of the present application proposes another production process of small particle size machine-made blue charcoal barbecue charcoal. The second embodiment is only a preferred mode of the first embodiment, and the implementation of the second embodiment will not affect the independent implementation of the first embodiment.

[0049] Specifically, the difference in the production process of the small particle size machine-made blue charcoal grilling charcoal provided by the second embodiment of the present application is that the production process of the small particle size mechanism blue charcoal grilling charcoal is that the blue charcoal in S1 is pulverized Up to three particle sizes: small particle size (particle size <0.5mm): medium particle size (particle size 0.5-1mm): large p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com