Steel-plastic composite anti-wear plate for water guide sealing structure of water turbine

A sealing structure, steel-plastic composite technology, applied in the direction of reaction engine, hydroelectric power generation, mechanical equipment, etc., can solve the problems of threatening the safe operation of the turbine, consuming materials and labor hours, and cavitation of the leak-proof ring of the turbine, and meeting the installation conditions. Less demanding, saving maintenance time, and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] Specific embodiments of the present invention will be described in detail below.

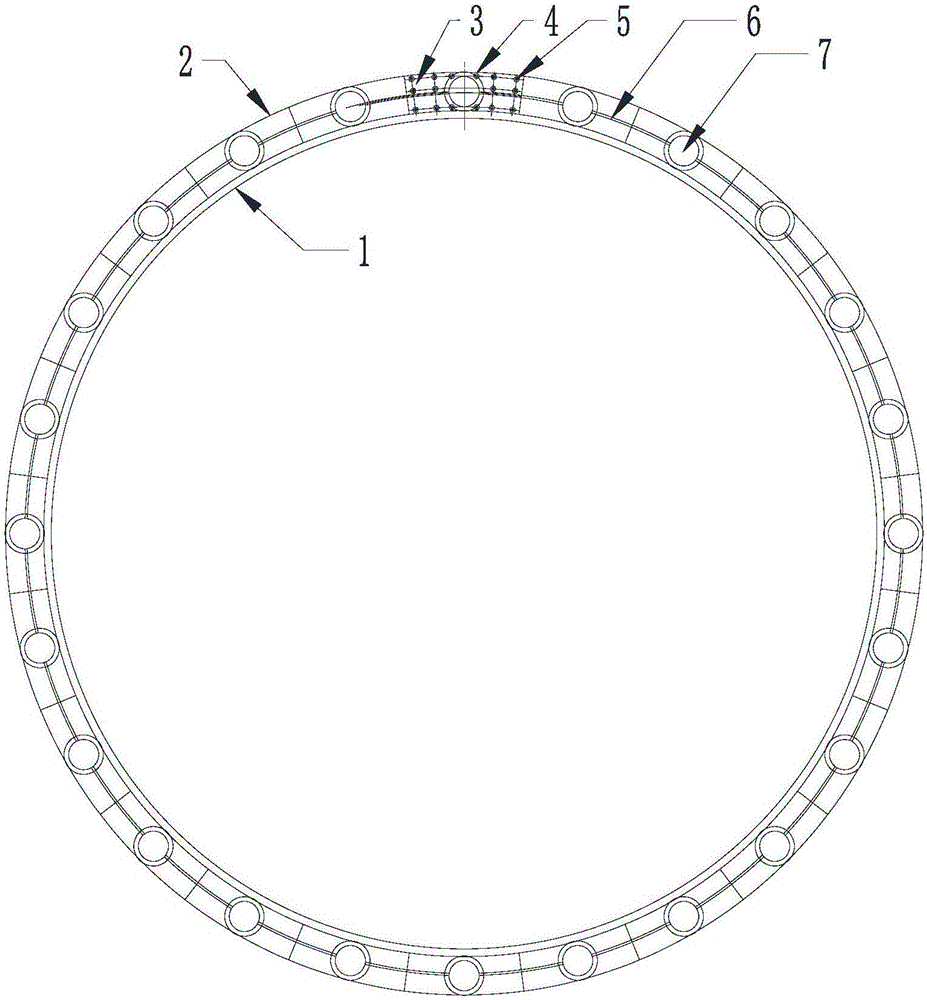

[0059] Such as Figure 1-11 As shown, a steel-plastic composite anti-friction plate for water-guiding sealing structure of a water turbine includes a bottom ring 1 of a water turbine and a top cover 13 of a water turbine,

[0060] The upper end surface of the bottom ring 1 of the water turbine is provided with a bottom ring anti-wear plate assembly 2,

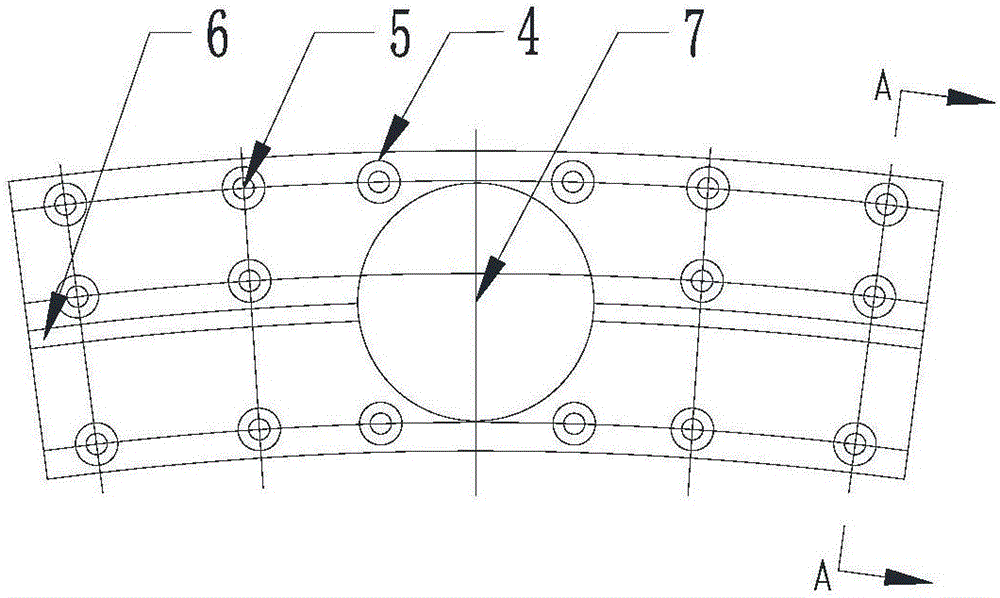

[0061] The bottom ring anti-wear plate assembly 2 includes a plurality of fan-shaped bottom ring anti-wear plate units 3 with the same structure, and the plurality of bottom ring anti-wear plate units 3 are evenly arranged along the upper end surface of the turbine bottom ring 1,

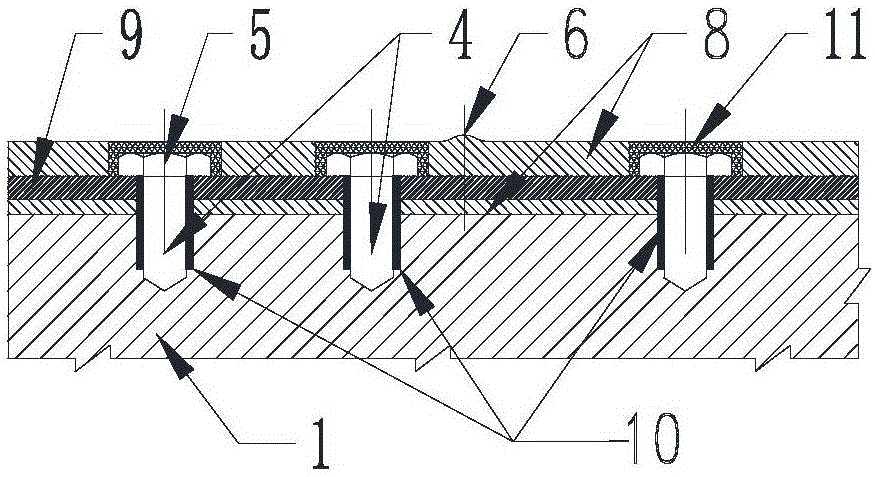

[0062]The bottom ring anti-wear plate unit 3 is made of a polyurethane elastomer 8 embedded with a first stainless steel skeleton 9, and the outer surface of the bottom ring anti-wear plate unit 3 is provided with a sealing protrusion 6 on the lower end surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com