Control method of hot rolling roughing mill

A control method and rough rolling mill technology, applied in rolling mill control devices, metal rolling, metal rolling, etc., can solve problems such as slabs cannot be bitten normally, slip, and affect production rhythm, so as to ensure production rhythm and increase transmission Speed, the effect of avoiding production accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

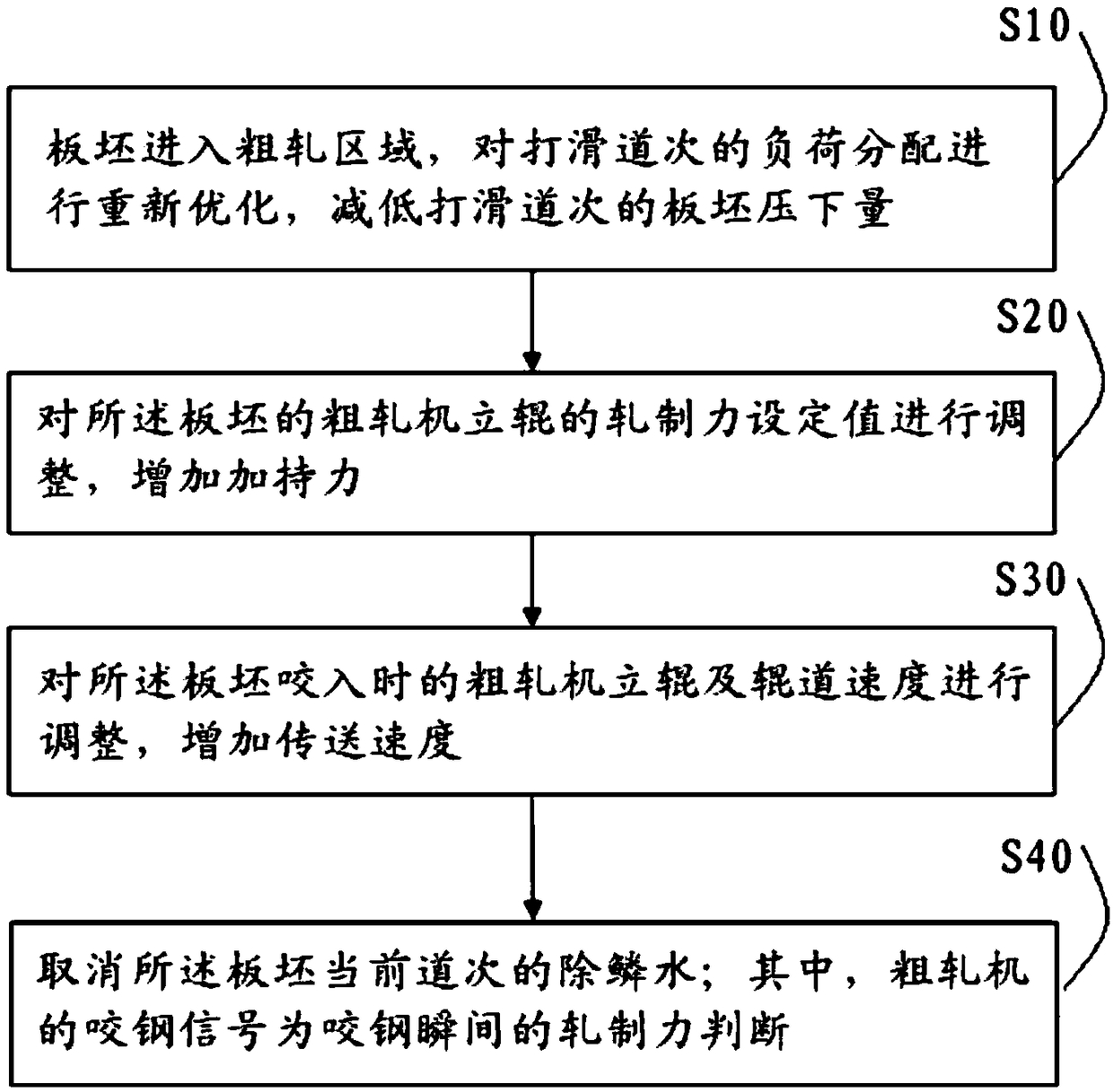

[0019] figure 1 It is a schematic flowchart of a control method for a hot rolling roughing mill in an embodiment of the present invention. Such as figure 1 As shown, the method includes:

[0020] Step 10: The slab enters the rough rolling area, re-optimizes the load distribution of the skid pass, and reduces the slab reduction in the skid pass;

[0021] Further, the slab enters the rough rolling area, re-optimizes the load distribution of the slipping pass, reduces the slab reduction of the slipping pass, and also includes: reducing the slab reduction of the slipping pass to 5- 10%.

[0022] Specifically, the rough rolling mill of the 2250mm hot rolling production line often slips during production, which seriously affects the rolling rhythm and the stability of the rolling mill. The slipping phenomenon in the normal rolling process means that the metal in the entire deformation zone is The roll moves in one direction. Among them, the reduction of the slab is one of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com