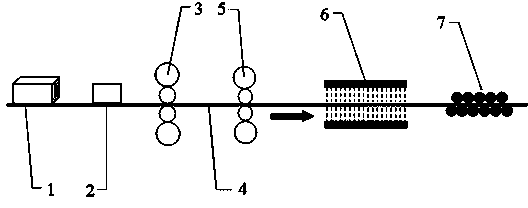

Process for producing thin gauge pipeline steel by using double-stand medium and heavy plate mill

A production process and thin-gauge technology, which is applied in metal rolling, manufacturing tools, metal rolling, etc., can solve the problems of inability to meet the production requirements of thin-gauge pipeline steel, rolling plate performance fluctuations, and low temperature at the head and tail of the rolled piece to reduce the curvature of the plate shape, avoid the stalling of the rolled piece, and speed up the rolling rhythm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A process for controlling the performance and shape of thin-gauge pipeline steel in a double-stand medium-heavy plate mill. The process requires a tapping temperature of 1190-1210°C, 12 rolling passes, and a roughing and finishing rolling temperature of ≥1040°C. The thickness of the intermediate billet is 3.9h, and the finish rolling temperature is 845-885°C; the reduction rate of the rough rolling pass is less than 21%, and the reduction rate of the longitudinal rolling pass after stretching to the required width of the finished product is ≤20.35%. The sub-reduction rate is less than 15%; the sled control function is used during the rough rolling process to reduce the warping degree of the head of the rolled piece, and the roll gap inclination value is dynamically adjusted during the finishing rolling process to improve the shape of the rolled piece body; After rolling, the steel is quickly thrown at a speed of 4m / s. The water temperature of the rolled piece is 760-800°...

Embodiment 2

[0028]A process for controlling the performance and shape of thin-gauge pipeline steel in a double-stand medium-heavy plate mill. The process requires a tapping temperature of 1190-1210°C, 12 rolling passes, and a roughing and finishing rolling temperature of ≥1040°C. The thickness of the intermediate billet is 3.6h (h is the thickness of the finished product), the finishing rolling temperature is 870-890°C; the reduction rate of the rough rolling pass is less than 10%, and the reduction rate of the longitudinal rolling pass after widening to the required width of the finished product is ≤26.97 %, the reduction rate of the final pass of finishing rolling is less than 15%; the sled control function is put into use during the rough rolling process, and the inclination value of the roll gap is dynamically adjusted during the finishing rolling process to reduce the warping degree of the head of the rolled piece and improve the body of the rolled piece After the finish rolling and f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com