Patents

Literature

56results about How to "Adapt to mass production requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Unmodified high-toughness low-temp steel for high-energy line welding and its production method

A high-toughness low-temp steel for high-energy linear welding contains C, Si, Mn, P, S, Al, Ti, N, B, Fe, and one or more of Cu, Ni, Nb, V, Mo and RE. The compound Ti-B oxide is used to obtain high welding performance under high linear energy (greater than 50 KJ / cm). Its low content of C and impurities can improve its toughness. Its advantags are high weld performance and low-temp toughness, andlow cost. It is suitable for low-temp spherical tank and large containers.

Owner:武钢集团有限公司

Steel series with high linear energy and low weld crack sensitivity and its preparing process

InactiveCN1396294ALow weld crack susceptibilityGood welding performanceUltimate tensile strengthPhase point

A high-strength steel as low-alloy steel contains low-C, Ti, Nb, B and two or more of Ni, V, Cu, Mo, Zr and RE, and is prepared through rolling and modifying heat-treatment to obtain high-toughness tempered sorbite texture and the high-smelting-point second-phase points and compound educed phase to suppress growth of welding coarse crystal region. Its advantages are high linear energy (60-70 kg) and low sensitivity to weld cracking.

Owner:武钢集团有限公司

Ultrahigh-strength atmospheric-corrosion resistant steel

The invention discloses a hyperstrength atmospheric corrosion-tolerant steel, which comprises the following parts: 0.01-0.07% C, 0.25-0.50% Si, 1.60-2.00% Mn, not more than 0.018% P, not more than 0.008% S, 0.20-0.50% Cu, 0.40-0.75% Cr, 0.25-0.60% Ni, 0.03-0.08% Nb, 0.10-0.40% Mo, not more than 0.02 Ti, not more than 0.035% Als, not more than 0.003% B and Fe and impurity.

Owner:武钢集团有限公司

Refractory anti-seismic construction steel for high-toughness welding structures, and production method thereof

InactiveCN101691643AImprove fire resistanceImprove seismic performanceChemical compositionRefractory

The invention discloses refractory anti-seismic construction steel for high-toughness welding structures, and a production method thereof, and solves the problem that the traditional construction steel is high in Mo that is a noble alloying element, high in producing-processing cost, low in refractory property and poor in anti-seismic performance. Based on the chemical composition of steel in percentage by weight, the steel comprises 0.05 to 0.13 percent of C, 0.10 to 0.60 percent of Si, 0.80 to 1.80 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.010 percent of S, 0.15 to 0.50 percent of Mo, 0.15 to 0.50 percent of Cr, 0.015 to 0.050 percent of Nb, and 0.010 to 0.050 percent of Als, at least one of 0.01 to 0.10 percent of V, 0.005 to 0.020 percent of Ti, 0.05 to 0.50 percent of Ni, 0.0010 to 0.020 percent of RE and 0.0010 to 0.010 percent of Ca, and the balance of Fe and inevitable impurities. The steel has the advantages of low content of Mo that is a noble alloying element, short production process and cycle, excellent refractory and anti-seismic performance, good cold-hot machining performance and excellent low-temperature toughness and welding performance.

Owner:武钢集团有限公司

LPG boat storage tank steel plate and production method thereof

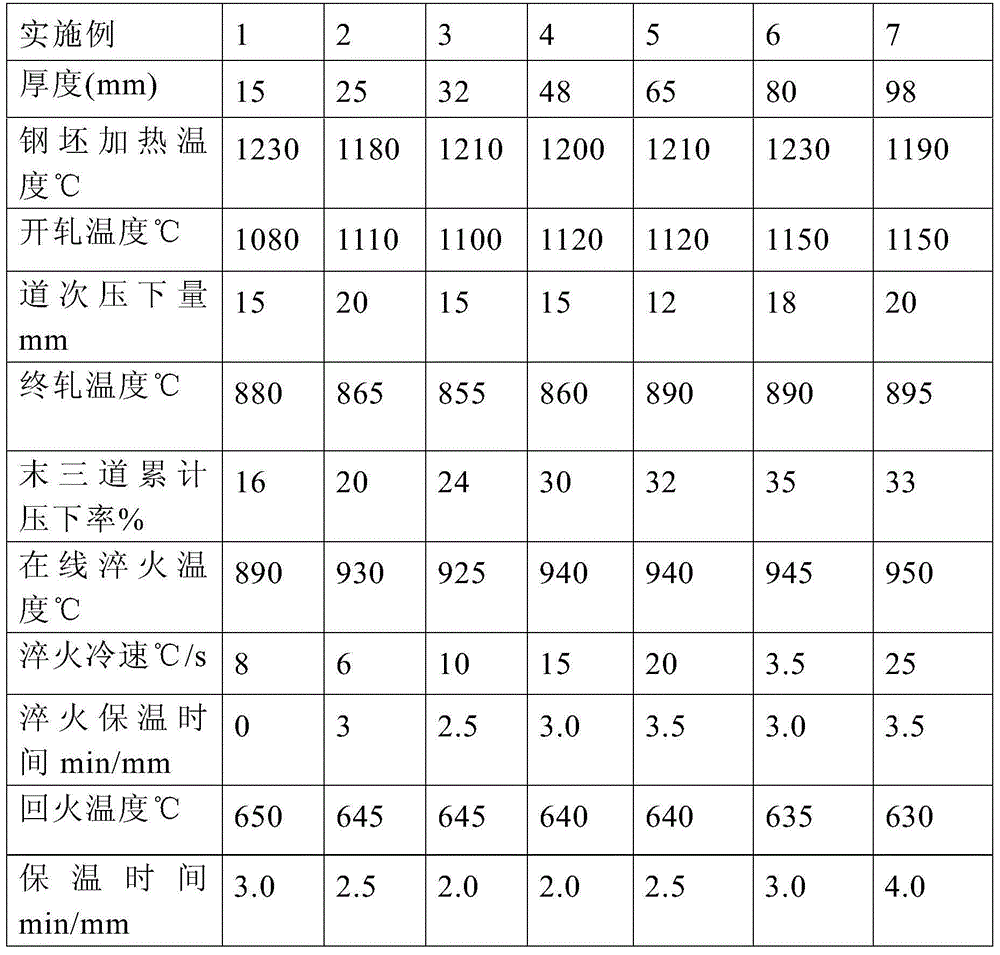

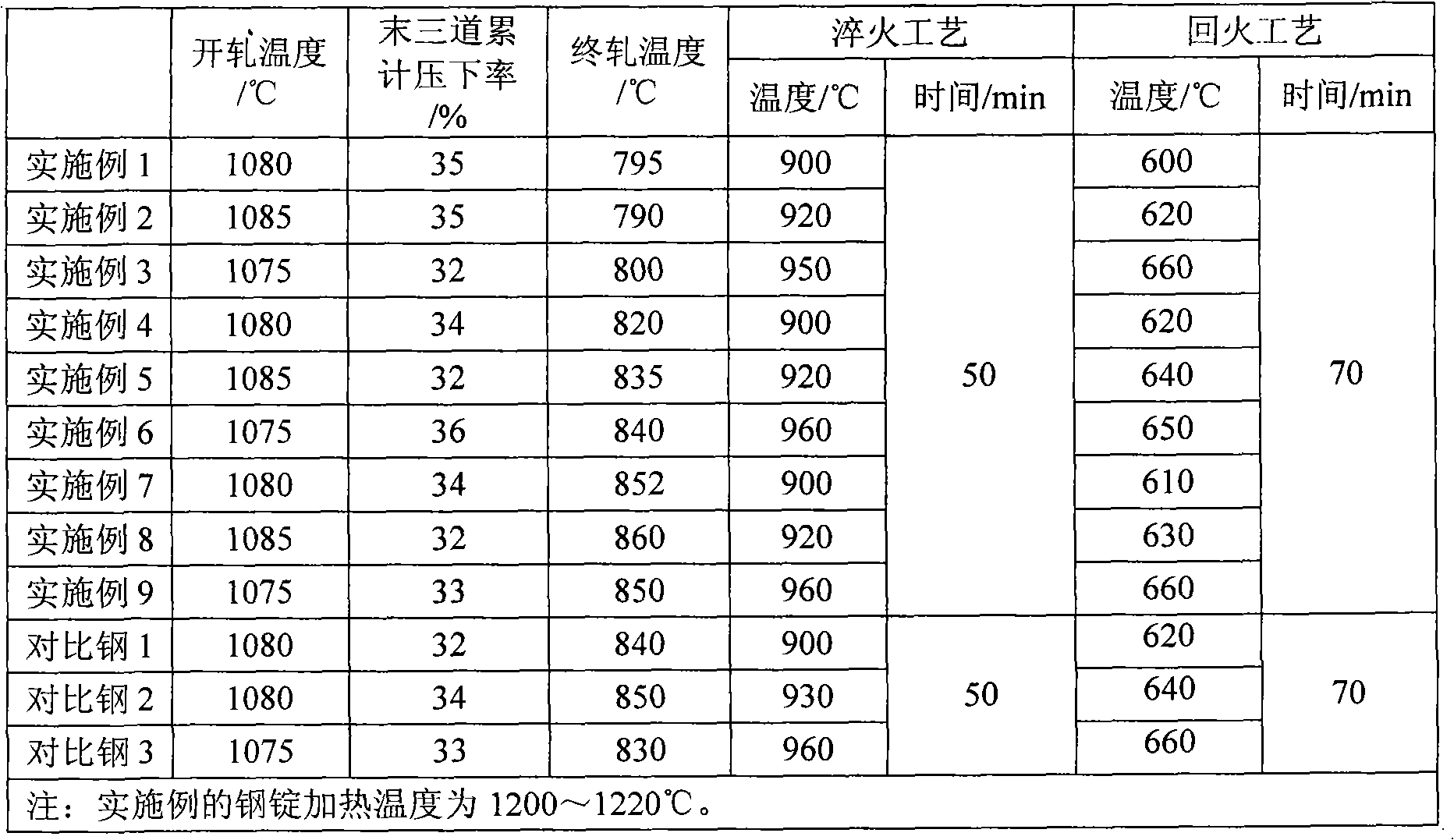

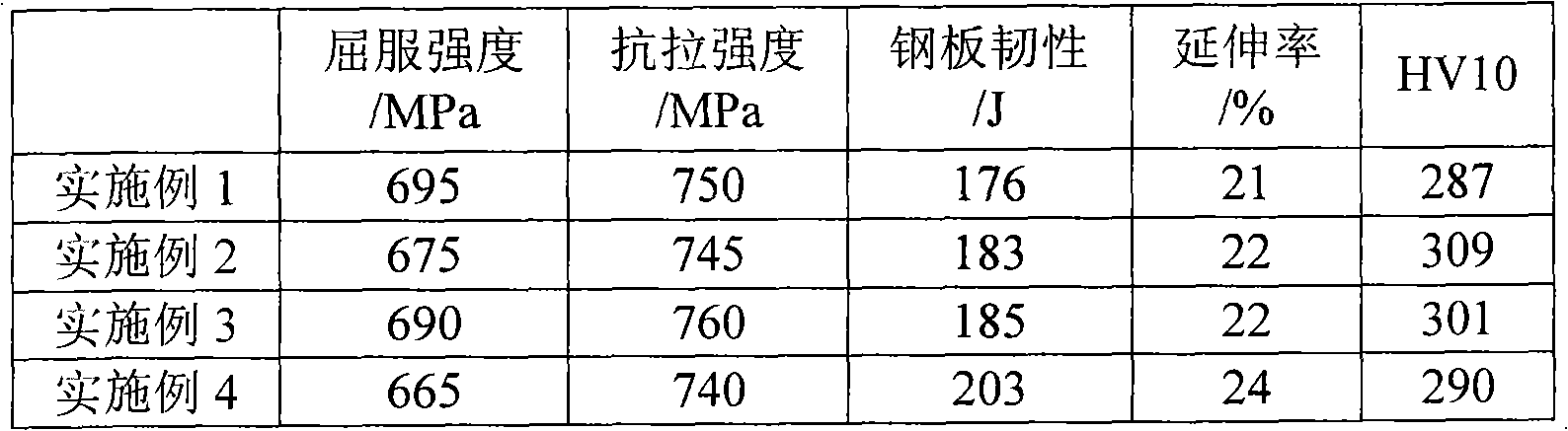

ActiveCN104131235AGood comprehensive mechanical propertiesGood cold and hot processing performanceQuenchingSteel plates

The invention discloses an LPG boat storage tank steel plate and a production method thereof. The steel plate comprises 0.05-0.12wt% of C, 0.30wt% or less of Si, 0.50-1.30wt% of Mn, 0.015wt% or less of P, 0.008wt% or less of S, 0.020-0.060wt% of Al, 0.15-1.20wt% of Cu, 0.20-1.50wt% of Ni, 0.35-1.00wt% of Cr, 0.20-0.60wt% of Mo, 0.008-0.020wt% of Ti, one or more of 0.0020-0.10wt% of Nb, 0.030-0.060wt% of V and 0.0005-0.0020wt% of B, and the balance Fe and inevitable impurities. The method comprises the steps of molten iron advanced desulphurization, converter top and bottom blowing, vacuum treatment, continuous casting, casting blank heating, rolling and heat treatment, the heating temperature of a casting blank is 1170-1250DEG C, and the heating rate of the casting blank is not less than 8min / cm; the blooming temperature is 1050-1150DEG C, the finishing temperature is 850-940DEG C, and the accumulated reduction rate of last three passes is not less than 16%; and heat treatment adopts online quenching and tempering treatment, or adopts offline quenching and tempering treatment. The steel plate obtained in the invention has the advantages of excellent mechanical properties, good hot and cold processing performance, excellent weldability and low sensitivity of weld cracks.

Owner:武汉钢铁有限公司

Low welding crack sensitivity steel with tensile strength at 700MPa level and production method thereof

ActiveCN101643888ATough enoughStrong enoughTemperature control deviceManufacturing convertersChemical compositionMetallurgy

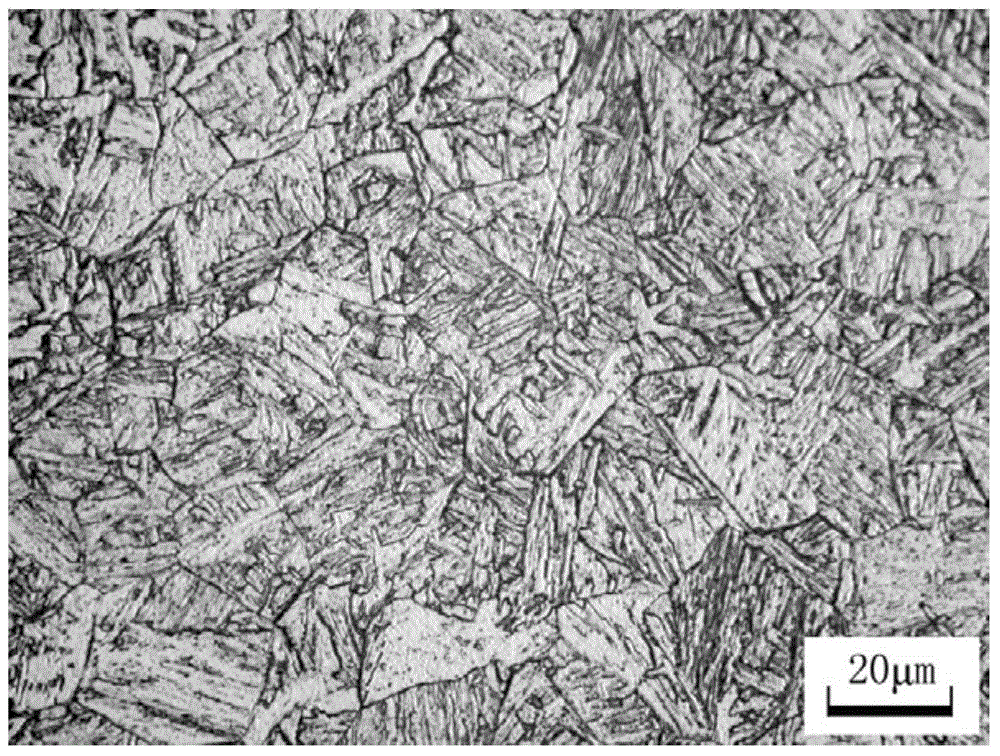

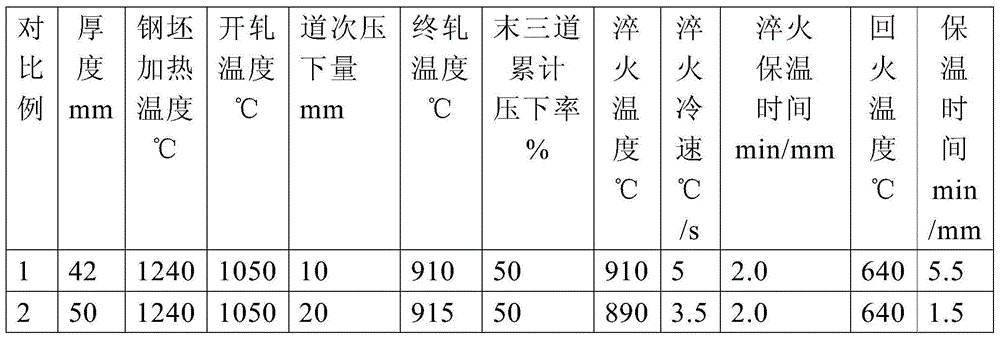

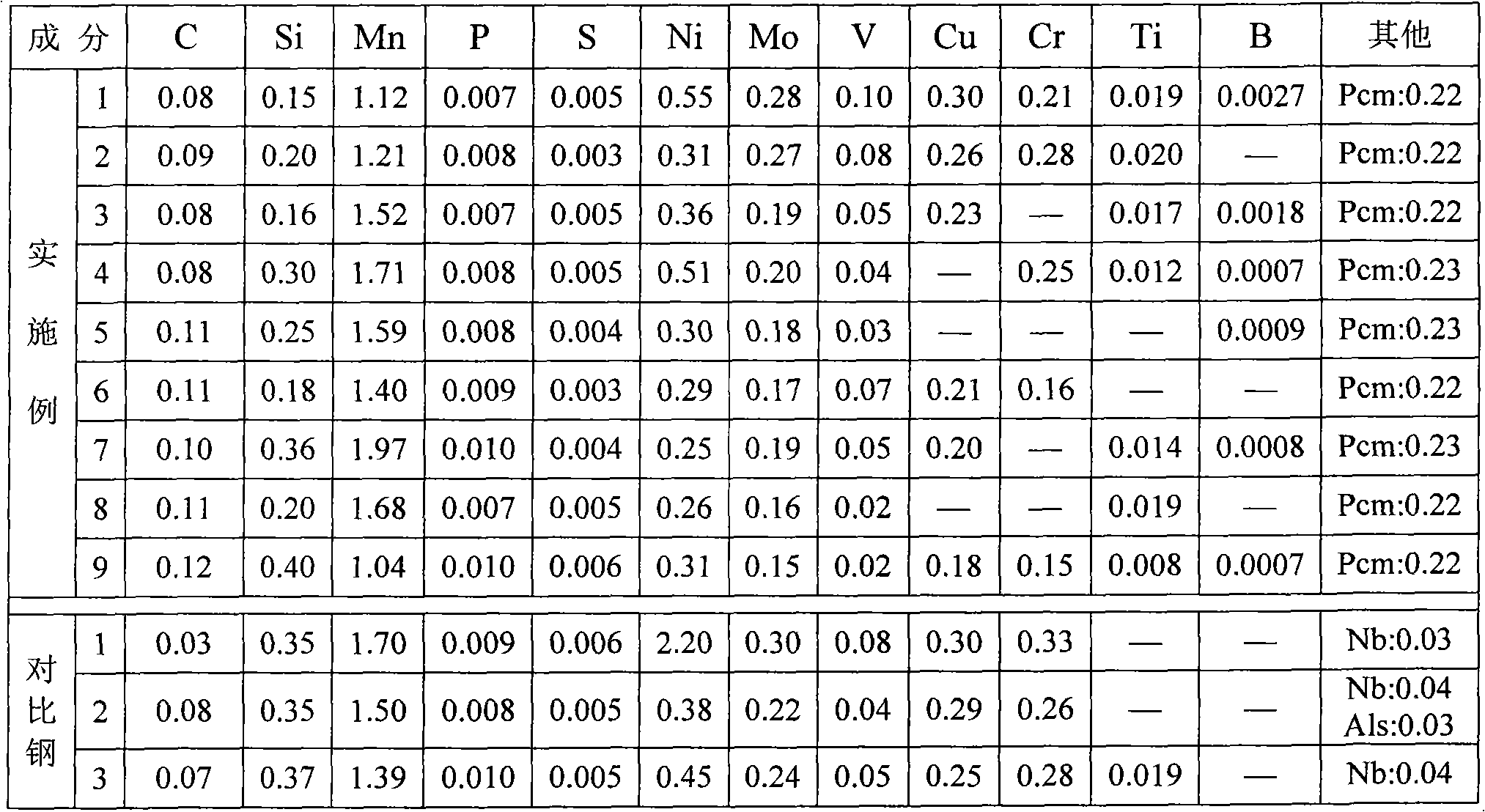

The invention provides low welding crack sensitivity steel with tensile strength at a 700MPa level and a production method thereof. The steel comprises the following two or more chemical components inpercentage by weight: C: 0.08-0.12, Si: 0.15-0.40, Mn: 1.00-2.00, P: smaller than or equal to 0.015, S: smaller than or equal to 0.006, Ni: 0.25-0.55, Mo: 0.15-0.28, V: 0.02-0.10, Cu: 0.18-0.30, Cr:0.15-0.30, Ti: 0.008-0.020 and B: 0.0007-0.0027 as well as the balance of Fe and inevitable impurities and also satisfies that Pcm is smaller than or equal to 0.24 percent and satisfies an equation: Pcm=C+Si / 30+Mn / 20+Cu / 20+Cr / 20+Ni / 60+Mo / 15+V / 10+5B (percent). The invention adopts a deep molten iron desulphurization technology, a converter top and bottom converting, vacuum treatment and continuouscasting processes and carries out rolling and hardening, tempering and thermal treatment production according to a general clean steel process.

Owner:武汉钢铁有限公司

High-performance weather-resisting anti-seismic steel for building and production method thereof

The invention relates to low alloyed steel used for building and a production method thereof, aiming at solving the defects that the prior building steel has atmospheric corrosion resisting property and does not consider the shock resistance problem. The invention adopts the measures that the low alloyed steel contains components by weight of 0.05-0.16 percent of C, 0.10-0.50 percent of Si, 0.60-1.50 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.010 percent of S, 0.15-0.60 percent of Cu, 0.25-0.80 percent of Cr, 0.10-0.50 percent of Ni, 0.01-0.10 percent of V, 0.005-0.030 percent of Ti at least one component of 0.010-0.040 percent of Nb, 0.010-0.050 percent of Als, 0.0010-0.0060 percent of Ca and 0.0010-0.020 percent of RE, and the rest of Fe and unavoidable impurities; and the production method comprises the following steps of molten iron desulphurizing and RH degassing, heating to 1150-1310 DEG C, rough rolling with the temperature being controlled at 1100-1200 DEG C and finishing rolling, wherein the beginning temperature of the finishing rolling is 880-980 DEG C, the rolling reduction ratio of each step is 15-30 percent, the final temperature of the finishing rolling is 800-900 DEG C, and the accumulated rolling reduction ratio of three steps of 35-50 DEG C.

Owner:WUHAN IRON & STEEL (GROUP) CORP

Manufacturing method of cold forming high intensity steel for welded structure

InactiveCN1563468AThe vertical and horizontal performance differences are narrowedImprove corrosion resistanceCold formedRare earth

This invention relates to a production method for cold forming high intensity welded construction steel taking low carben-Mn as the basis, added by Nb, Ti microalloy as the main composition and applying melted iron desulfurization technology, converter top and bottom combined blowing and vacuum process, among which, the melted steel is casted to slab after rare earth or Ca to be casted to slab process then to be rolled to cut deal or hot rolled plate by cut deal production technology or the hot tandem rolling technology.

Owner:武钢集团有限公司

High-energy welded high-toughness steel for resisting corrosion of molten zinc and its preparing process

A high-toughness steel welded with high linear energy (More than 50 KJ / cm) and resisting molten zinc corrosion is prepared through converter smelting at 1250-1320 deg.C, vacuum treating, and rolling at 1000-1180 deg.c or lower than 950 deg.C and cumulative drafts rate is greater than or aqual to 50%. It features that composite Ti oxide is used to resist high linear energy, the Nb, V, etc. and used for raising strength, and the Cu, Ni, B and RE are used to resist molten zinc corrosion. Its advantages are simple technology with high efficiency, low cost, and high performance of finished steel.

Owner:武钢集团有限公司

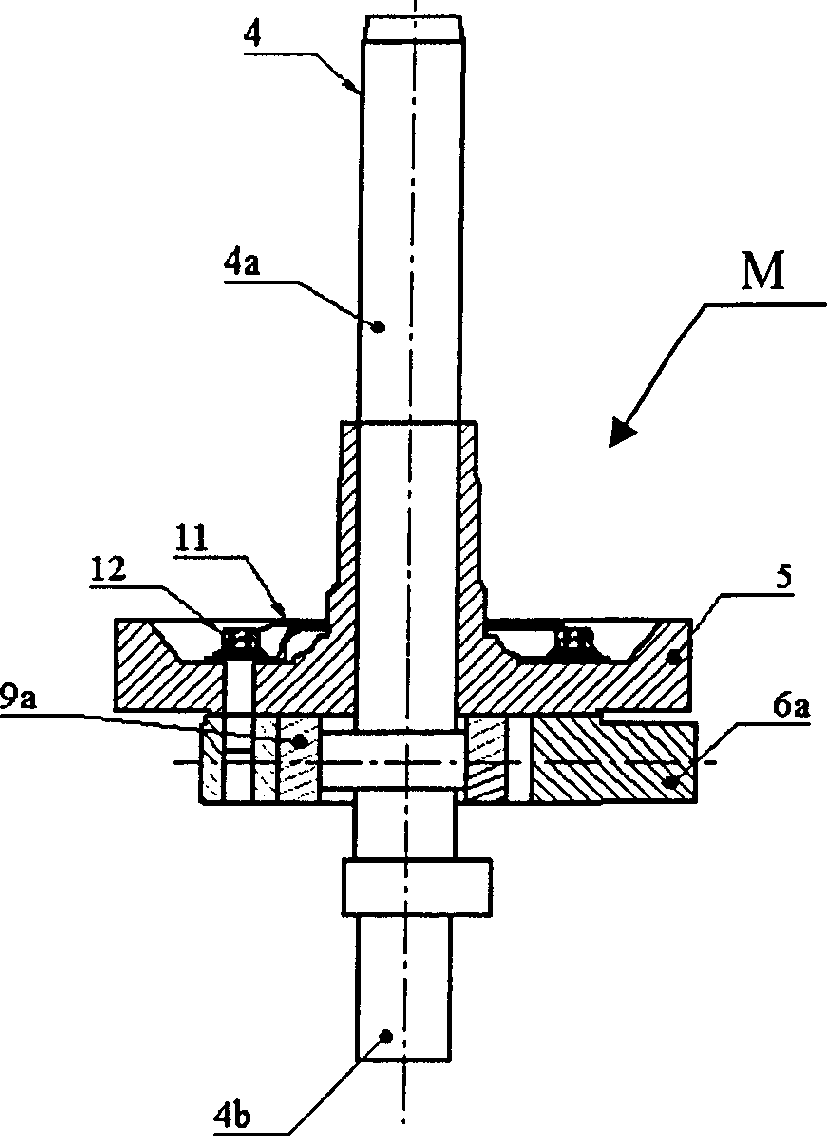

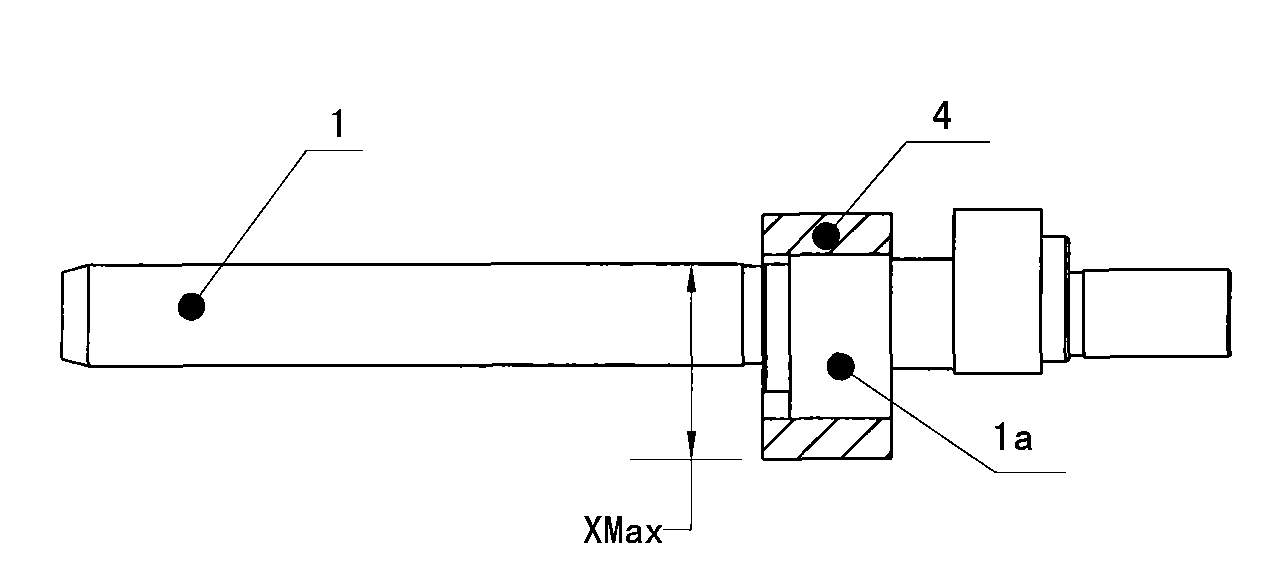

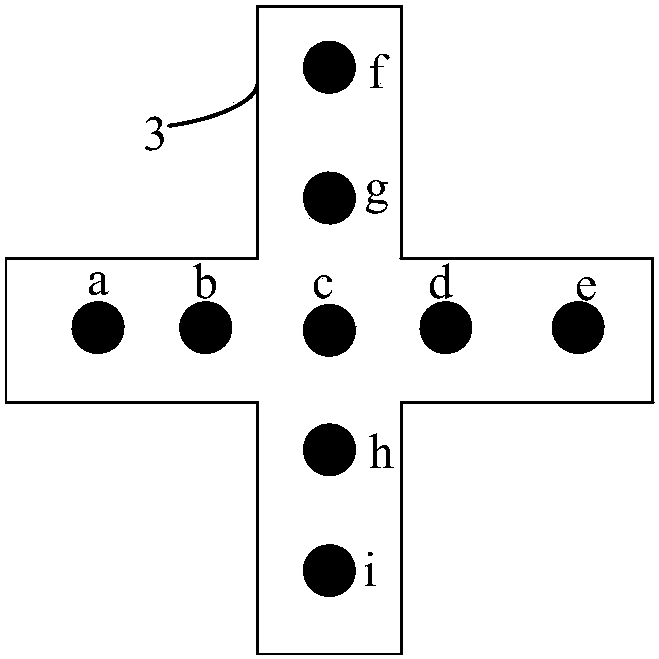

Method for assembling pump-body of compressor with revolving twin cylinder

ActiveCN1796790ASimple processReduce processRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsMechanical engineeringCrankshaft

A method for assembling pump of double cylinder rotary compressor includes forming M assembly by confirming top and bottom eccentric dimension and setting top and bottom piston on them as well as measuring maximum distance of top piston outer diameter ( OD ) to long shaft another side OD and bottom piston OD to short shaft the same side OD, setting top silencer and top cylinder cover as well as top cylinder, regulating them and inserting piston and crankshaft; forming N assembly by setting intermediate plate and bottom cylinder, regulating and fixing them; laying bottom cylinder cover and bottom silencer down then fixing them.

Owner:SHANGHAI HITACHI ELECTRICAL APPLIANCES CO LTD

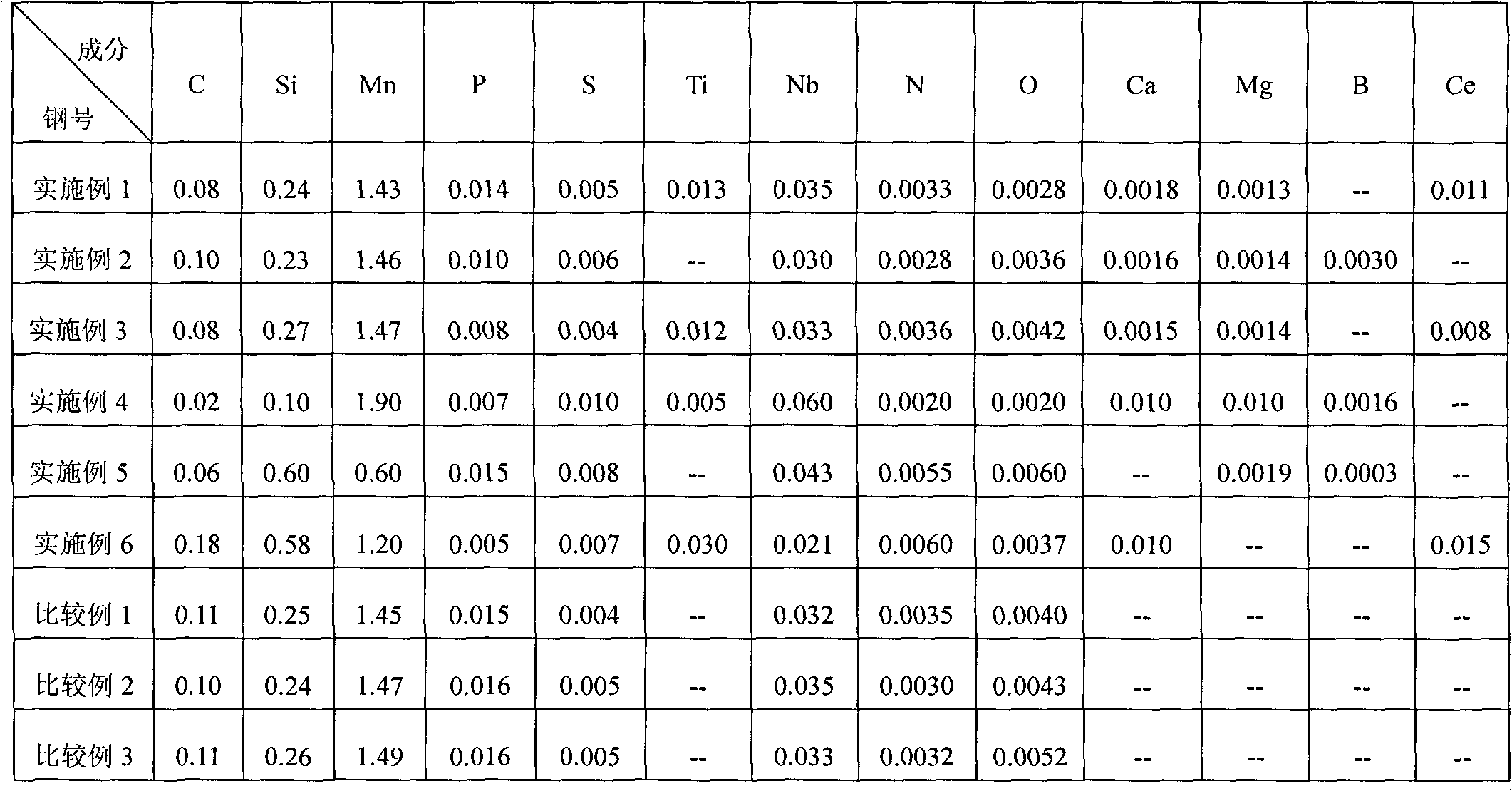

Ultra-large linear energy input welding high-strength steel and production method thereof

InactiveCN101818304AImprove mechanical propertiesImprove toughnessRoll mill control devicesMetal rolling arrangementsSheet steelChemical composition

The invention discloses ultra-large linear energy input welding high-strength steel and a production method thereof, and solves the problems of high alloying cost, poor welding performance of steel plates and low HAZ impact toughness of the conventional large linear energy input welding high-strength steel. The steel comprises the following chemical compositions in percentage by weight: 0.02 to 0.18 percent of C, 0.10 to 0.60 percent of Si, 0.60 to 1.90 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.010 percent of S, less than or equal to 0.060 percent of Nb, 0.0020 to 0.0060 percent of N, 0.0020 to 0.0060 percent of O, and at least two of 0.005 to 0.030 percent of Ti, less than or equal to 0.010 percent of Ca, less than or equal to 0.010 percent of Mg, 0.0003 to 0.003 percent of B, and 0.008 to 0.015 percent of Ce, and the balance of Fe and inevitable impurities. In addition, the chemical compositions meet the following conditions: (1) 4.0C+Mn is less than or equal to 2.1; (2) the carbon equivalent CE is equal to C+Si / 24+Mn / 6+Ni / 40+Cr / 5+Mo / 4+V / 14 and is less than or equal to 0.39. A casting blank with the compositions is prepared through hot metal desulphurization, converter top and bottom blowing, vacuum deep treatment and fine adjustment of the compositions, the casting blank subjected to controlled rolling is air-cooled to room temperature, and the high-strength strong-toughness and excellent-match steel is obtained. The steel has the advantages of high strength, excellent low temperature toughness, and high Z-direction performance, and can bear ultra-large linear energy input (more than or equal to 500kJ / cm) welding.

Owner:武钢集团有限公司

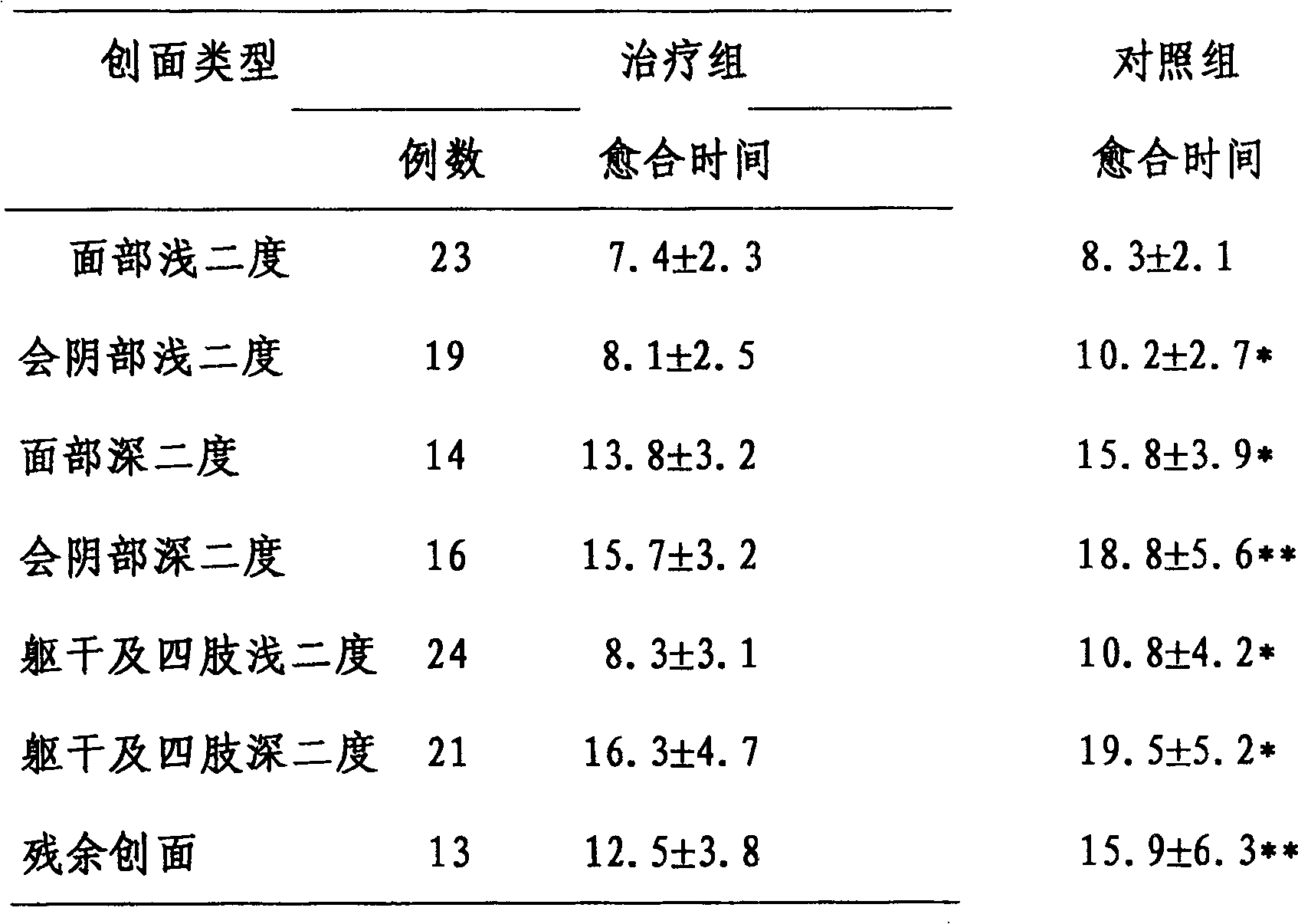

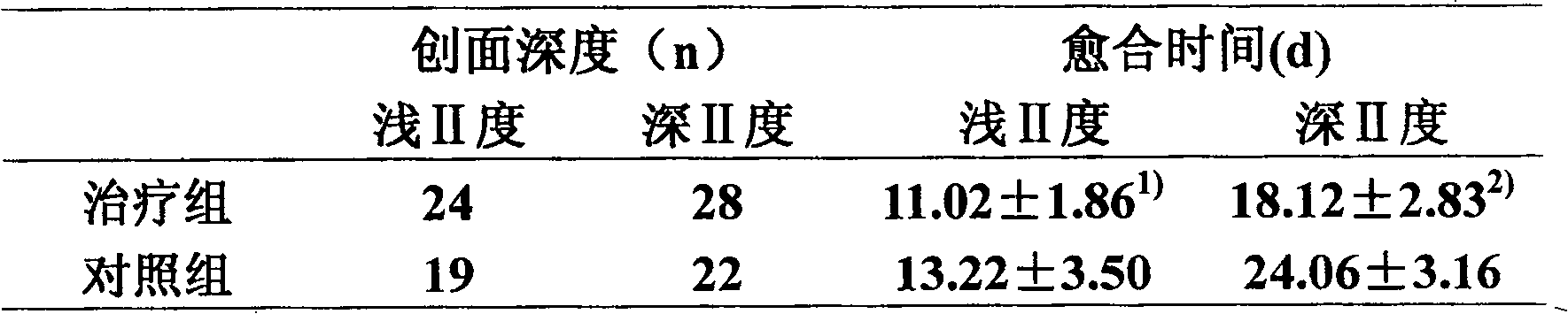

Wound-protection liquid, and its preparing method

ActiveCN100560057CNo side effectsShorten wound healing timeInorganic active ingredientsPharmaceutical delivery mechanismSide effectNecrotic tissue

Owner:苏州汇涵医用科技发展有限公司

Ti-contained sulphuric acid dew-point corrosion resisting steel with tensile strength not less than 450 MPa)

The invention relates to a Ti-contained sulphuric acid dew-point corrosion resisting steel with tensile strength not less than 450 MPa). The invention overcomes the defects of low sulphuric acid dew-point corrosion resistance and the like. the Ti-contained sulphuric acid dew-point corrosion resisting steel comprises the following chemical components in percentage by weight: 0.025-0.15% of C, 0.10-0.50% of Si, not more than 1.50% of Mn, not more than 0.020% of P, not more than 0.010% of S, 0.10-0.60% of Cu, 0.05-0.80% of W, 0.06-0.13% of Ti, not more than 0.080% of Al and balance of Fe and inevitable inclusions; and the sum of Cu, W and Ti is greater than 0.065% and smaller than 1.60%. The yield strength of the steel is at least 330 MPa, the tensile strength is not less than 450 MPa, and the percentage of elongtation is not less than 22%. The steel is delivered in the hot rolling state. The invention has the advantages of simple technique, low cost, favorable toughness match and favorable welding performance, and can be widely used for manufacturing boiler low-temperature components, flues, chimneys, tobacco curing boxes and special desulfurization equipment, thereby being beneficial to popularization and application.

Owner:武钢集团有限公司

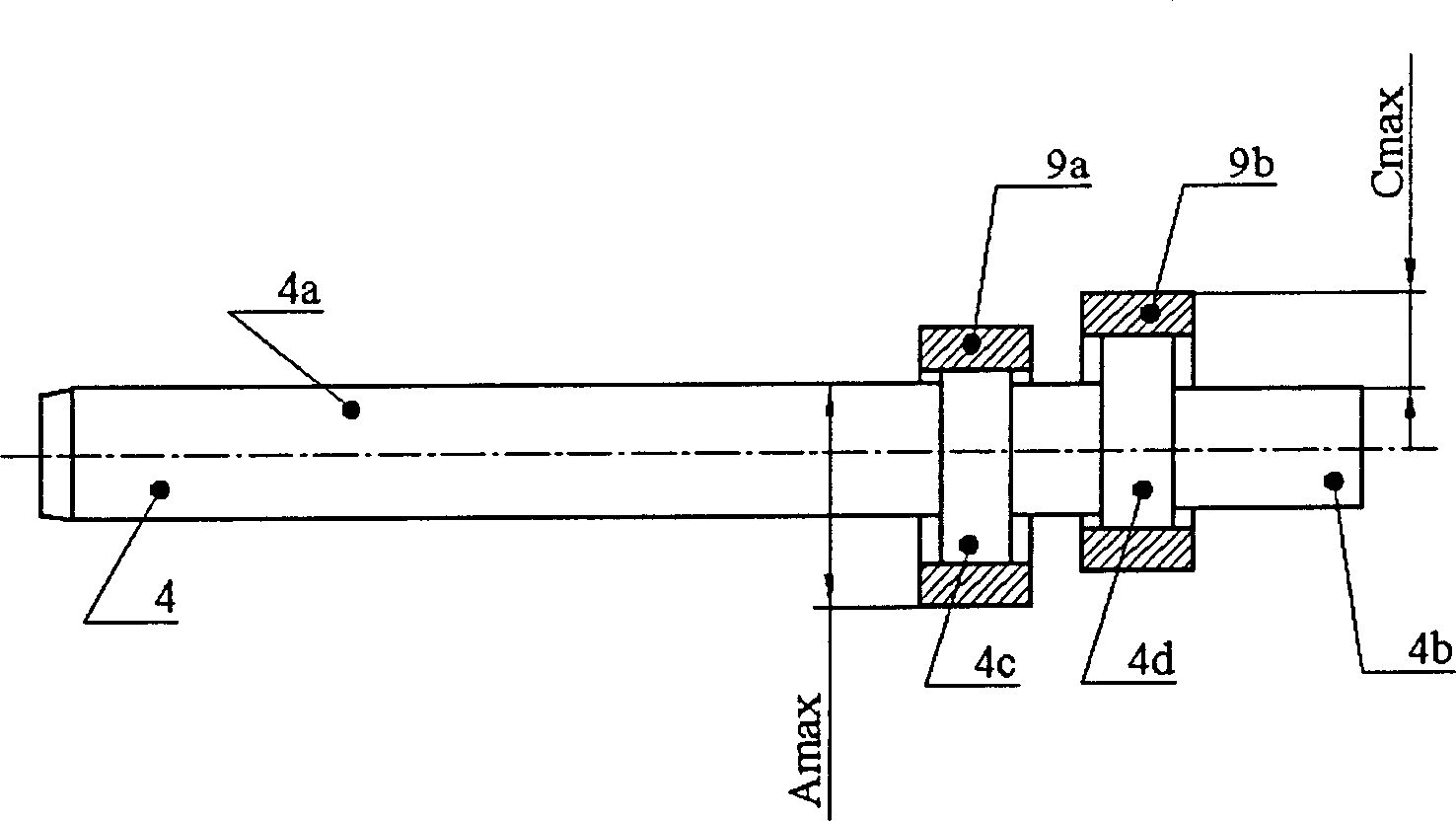

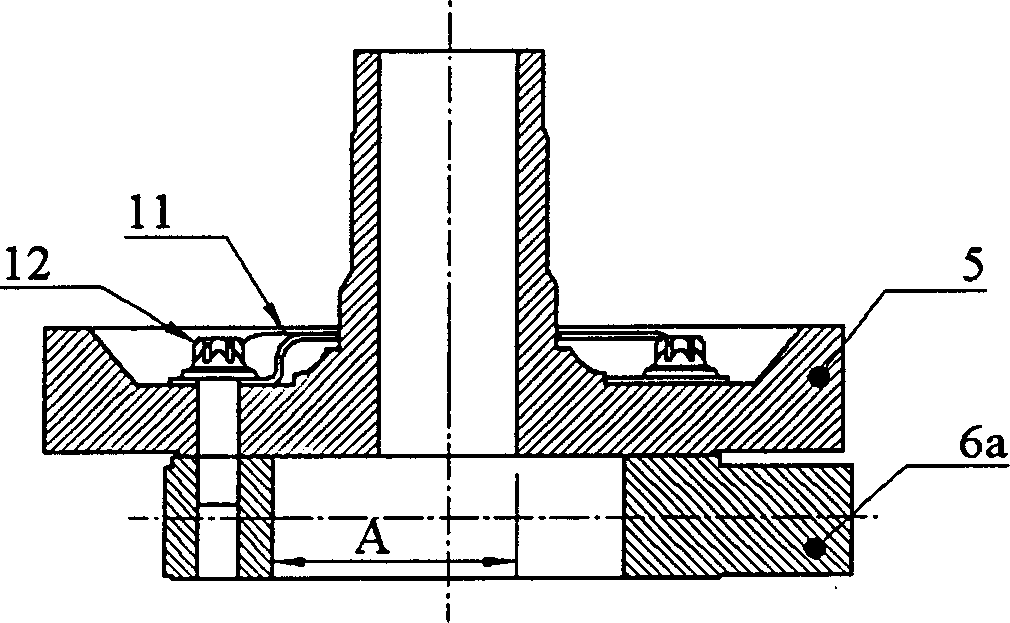

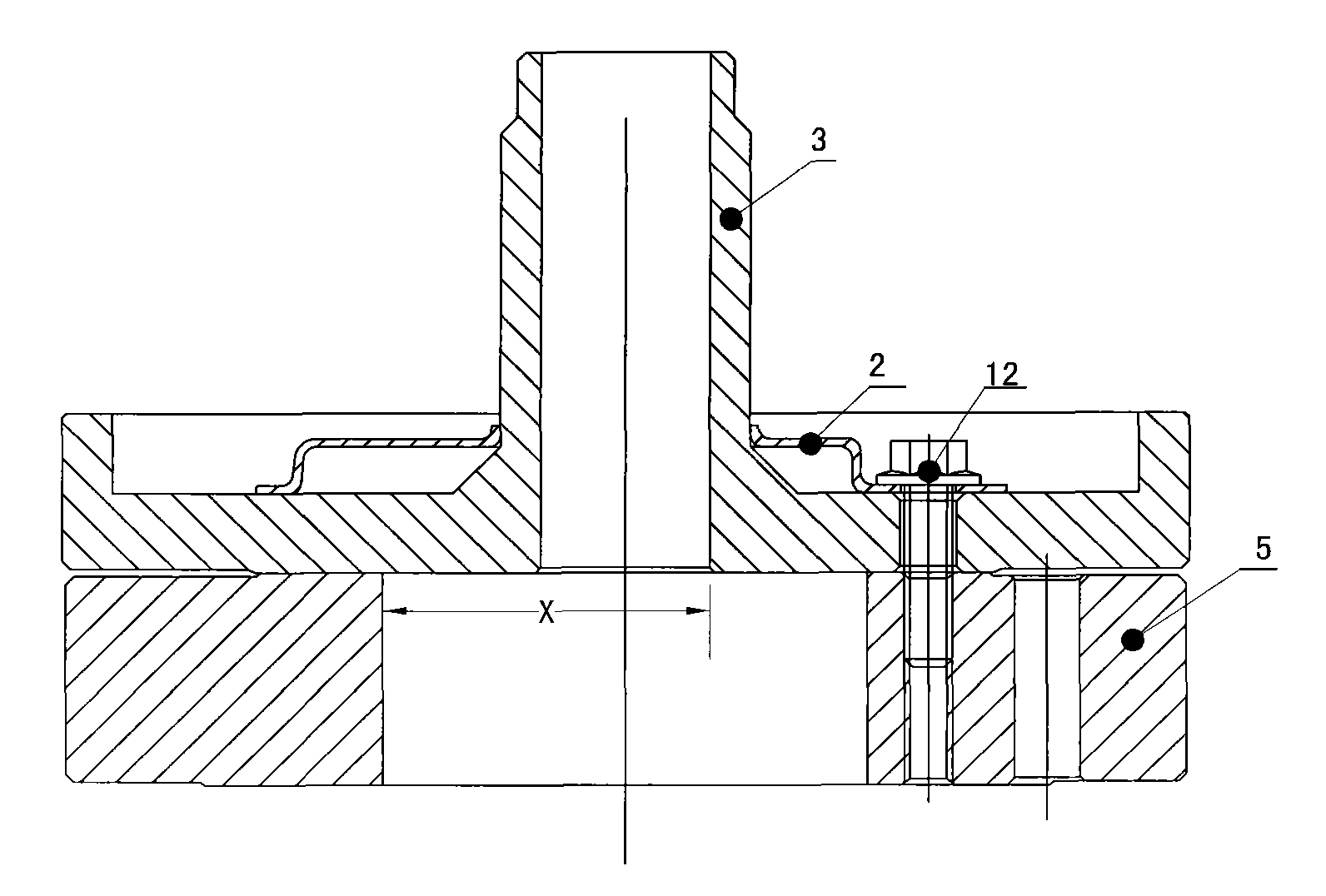

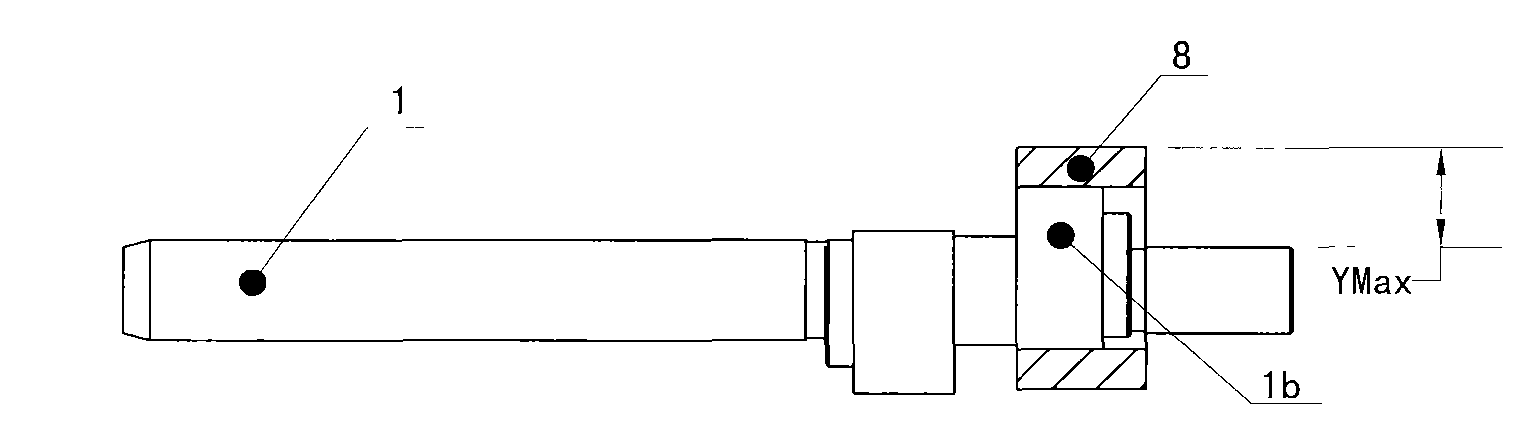

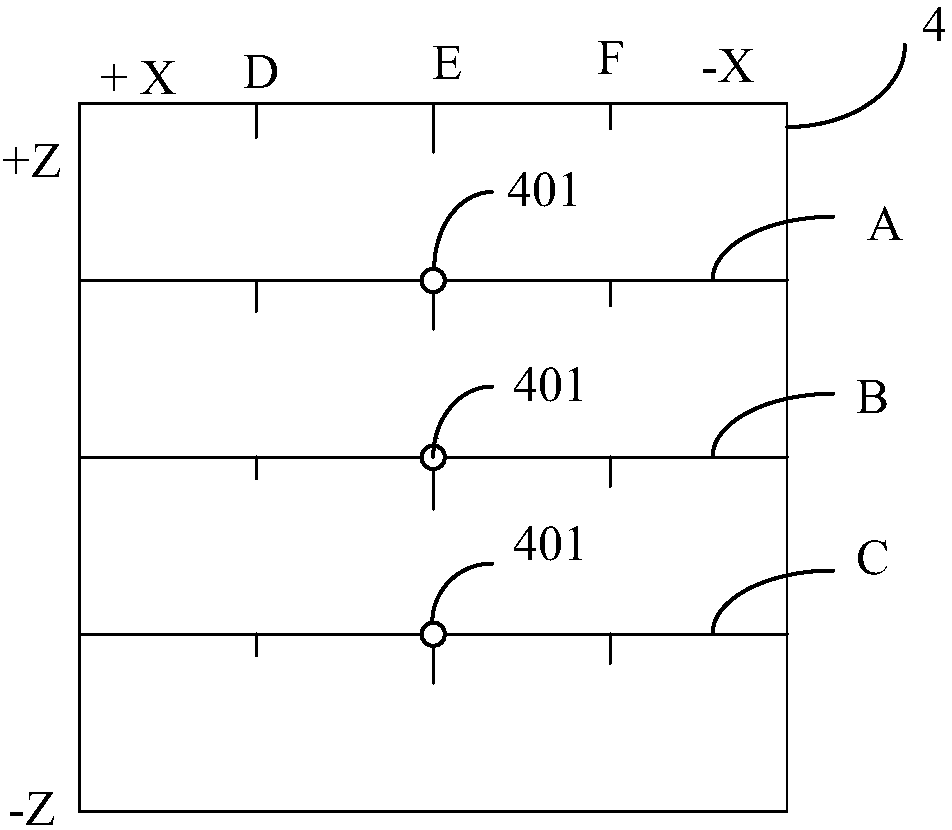

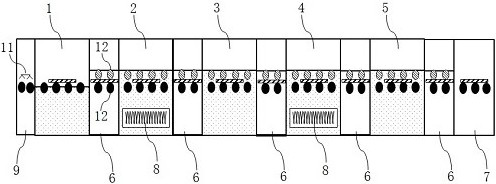

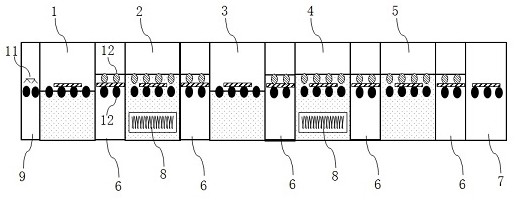

Method for assembling pump body of double-cylinder rotary compressor

InactiveCN101929462ASimple processGuaranteed assembly qualityRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsMinor axisCrankshaft

The invention provides a method for assembling a pump body of a double-cylinder rotary compressor. The method can enhance the precision of the pump body assembly gap, has the advantages of simple procedure and low cost, can ensure the assembly quality and can meet the requirements for large batch production. The method comprises the following steps: adjustment of upper eccentric gap: adjusting the difference, namely the value of the upper eccentric gap between the maximum distance from the outer diameter of an upper roller to the outer diameter at the opposite side of the major axis of the crank shaft and the distance from the inner circle of the upper cylinder to the inner circle of the upper flange at the opposite side, so that the value of the upper eccentric gap is within the preset range of 10-50 mu m; adjustment of lower eccentric gap: adjusting the difference, namely the value of the lower eccentric gap between the maximum distance from the outer diameter of the lower roller to the outer diameter at the same side of the minor axis of the crank shaft and the distance from the inner circle of the lower cylinder to the outer circle at the same side of the minor axis of the crank shaft, so that the value of the lower eccentric gap is within the preset range of 10-50 mu m; and concentric assembly: concentrically assembling the upper flange and the lower flange.

Owner:GREE ELECTRIC APPLIANCES INC

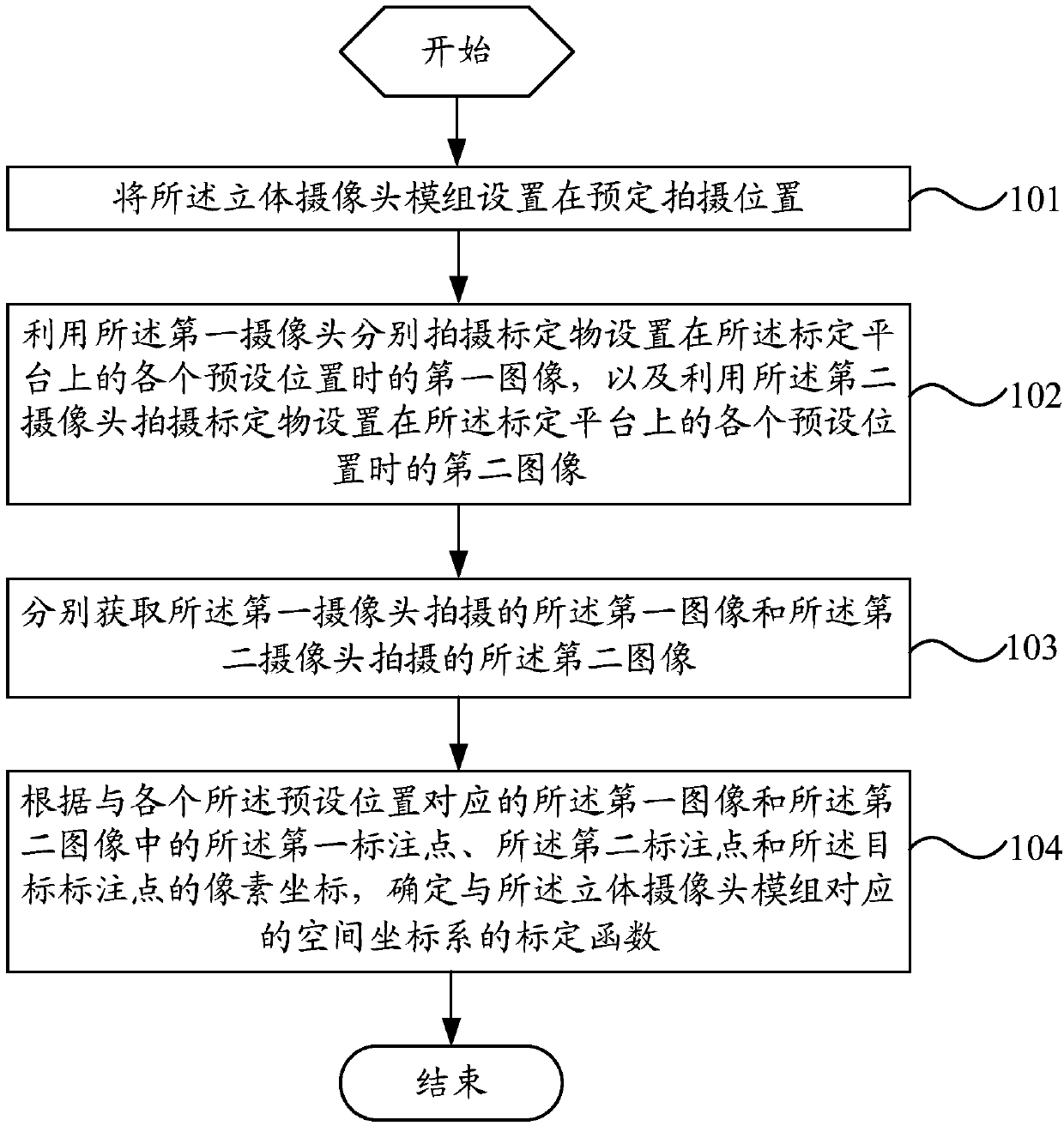

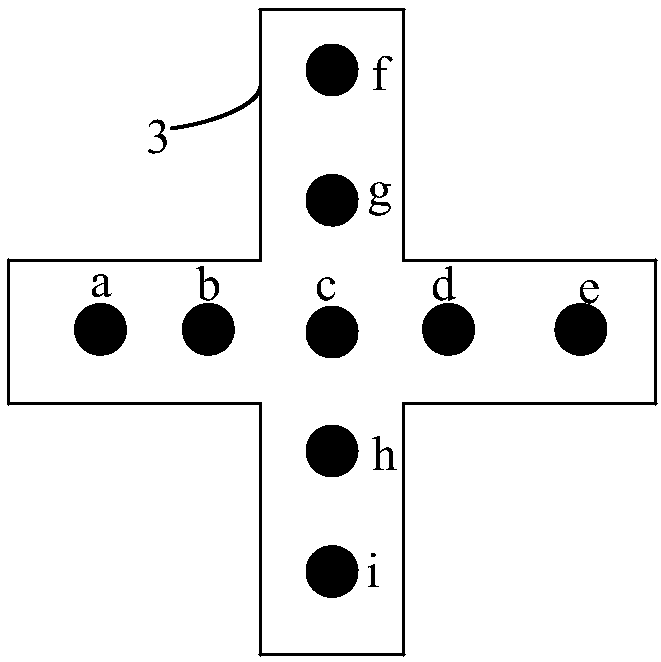

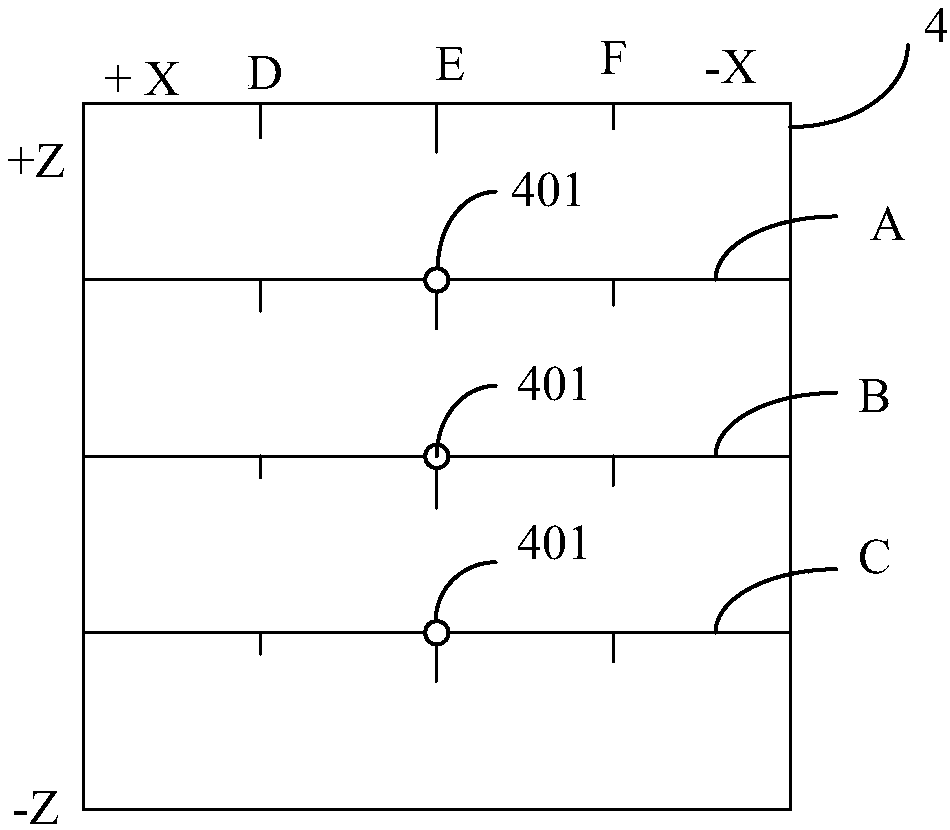

Three-dimensional camera module group calibration method and device

InactiveCN108257182AAccurate grasp of precisionSolve the problem that the accuracy is difficult to controlImage enhancementImage analysisSpatial positioningCamera module

The invention provides a three-dimensional camera module group calibration method and device. The calibration method comprises the steps that the first image of a calibration object when the calibration object is arranged on each preset position of the calibration platform is photographed by using a first camera, and the second image of the calibration object when the calibration object is arranged on each preset position of the calibration platform is photographed by using a second camera; the first images photographed by the first camera and the second images photographed by the second camera are respectively acquired; and the calibration function of a space coordinate system corresponding to the three-dimensional camera module group is determined according to the pixel coordinates of the first mark points and the second mark points in the first images and the second images corresponding to each preset position and the target mark point. Therefore, calibration of the internal parameters and the external parameters of the cameras is not involved, and standardization is easy so that the accuracy of spatial positioning through the three-dimensional camera module group can be accurately mastered.

Owner:SUPERD CO LTD

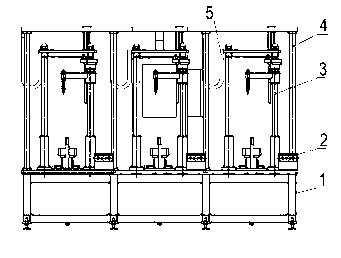

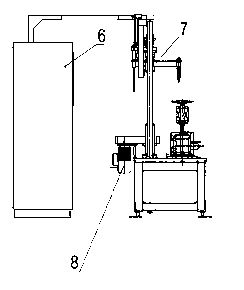

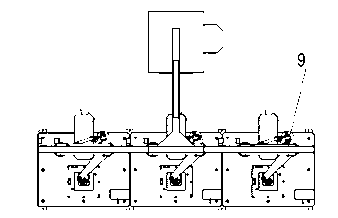

Novel device assembling stator and rotor of motor in combined mode

ActiveCN103219835AShorten assembly cycle timeAdapt to mass production requirementsElectric machinesManufacturing dynamo-electric machinesHigh volume manufacturingElectric machine

The invention relates to a novel device assembling a stator and a rotor of a motor in a combined mode, in particular to novel equipment suitable for assembling the stator and the rotor of a traction motor of a new energy electric car in the combined mode. The novel device assembling the stator and the rotor of the motor in the combined mode comprises a workbench, guidepost parts, guidepost mobile parts, electrical control cabinets, control boxes, a bus duct and support, wire protective chains, upper tips, mobile parts and upper swinging frame parts. Machine assembling replaces manual assembling, assembling beats are shortened, the novel assembling device is suitable for meeting the needs of mass production, workpieces can be hung in and hung out without a hitch, the device can be operated conveniently, rotor parts can be lifted and descended at will, both hands are available to enable motor wires to be pulled outwards simultaneously from a rear end cover of the motor, the assembling efficiency is high, and multi-kind assembling can be achieved.

Owner:大连德欣新技术工程有限公司

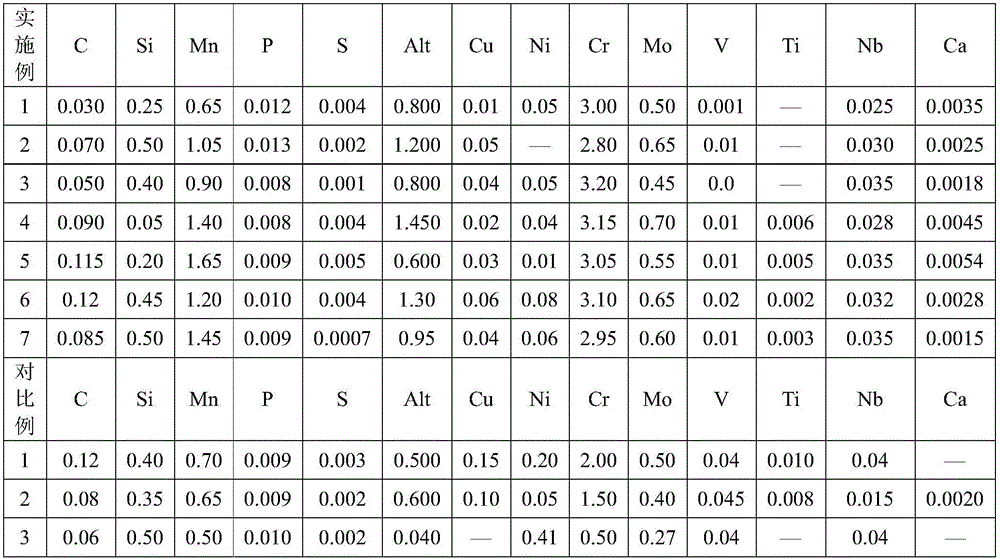

High temperature-resistant and hydrogen sulfide corrosion-resistant steel plate for pressure vessels and manufacturing method thereof

ActiveCN106435396AEasy to spreadImprove high temperature creep resistanceChemical compositionHigh pressure

The invention discloses a high temperature-resistant and hydrogen sulfide corrosion-resistant steel plate for pressure vessels. The steel plate mainly comprises, by weight, 0.03%-0.12% of C, 0-0.60% of Si, 0.50%-1.70% of Mn, 0-0.015% of P, 0-0.008% of S, 0.40%-1.50% of Al, 2.75%-3.25% of Cr, 0.30%-0.70% of Mo, 0.020%-0.035% of Nb, and the balance Fe and inevitable impurities. By the adoption of the type of steel, high temperature mechanical properties in the high temperature condition of 350 DEG C or above can be improved obviously, the fracture toughness and impact toughness of the steel plate are not lowered, and the high temperature resistance, high pressure resistance and hydrogen sulfide resistance are achieved.

Owner:武汉钢铁有限公司

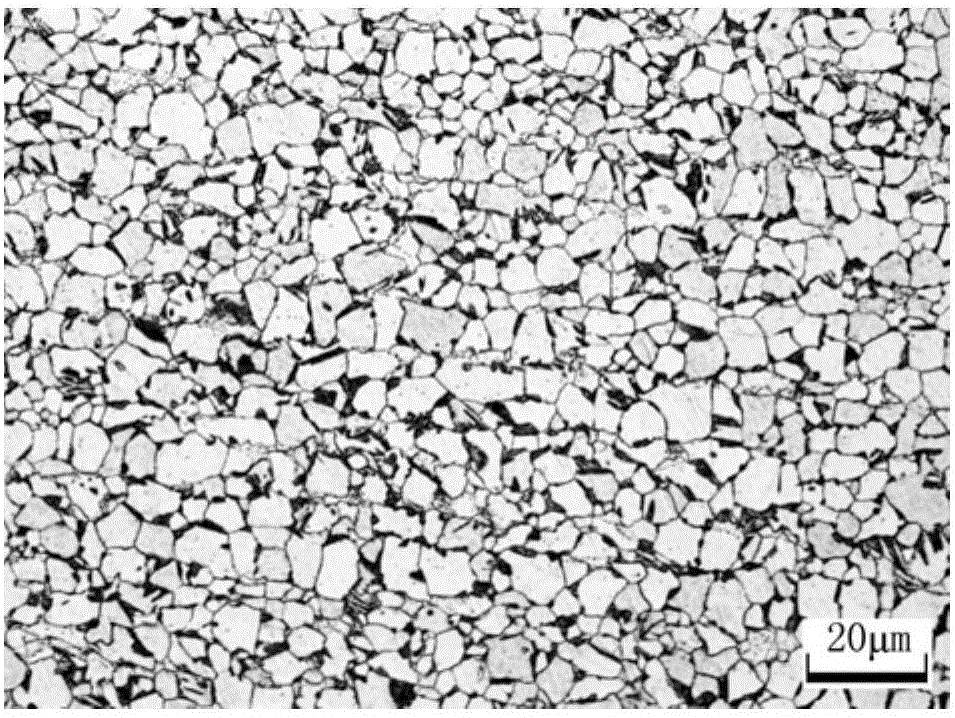

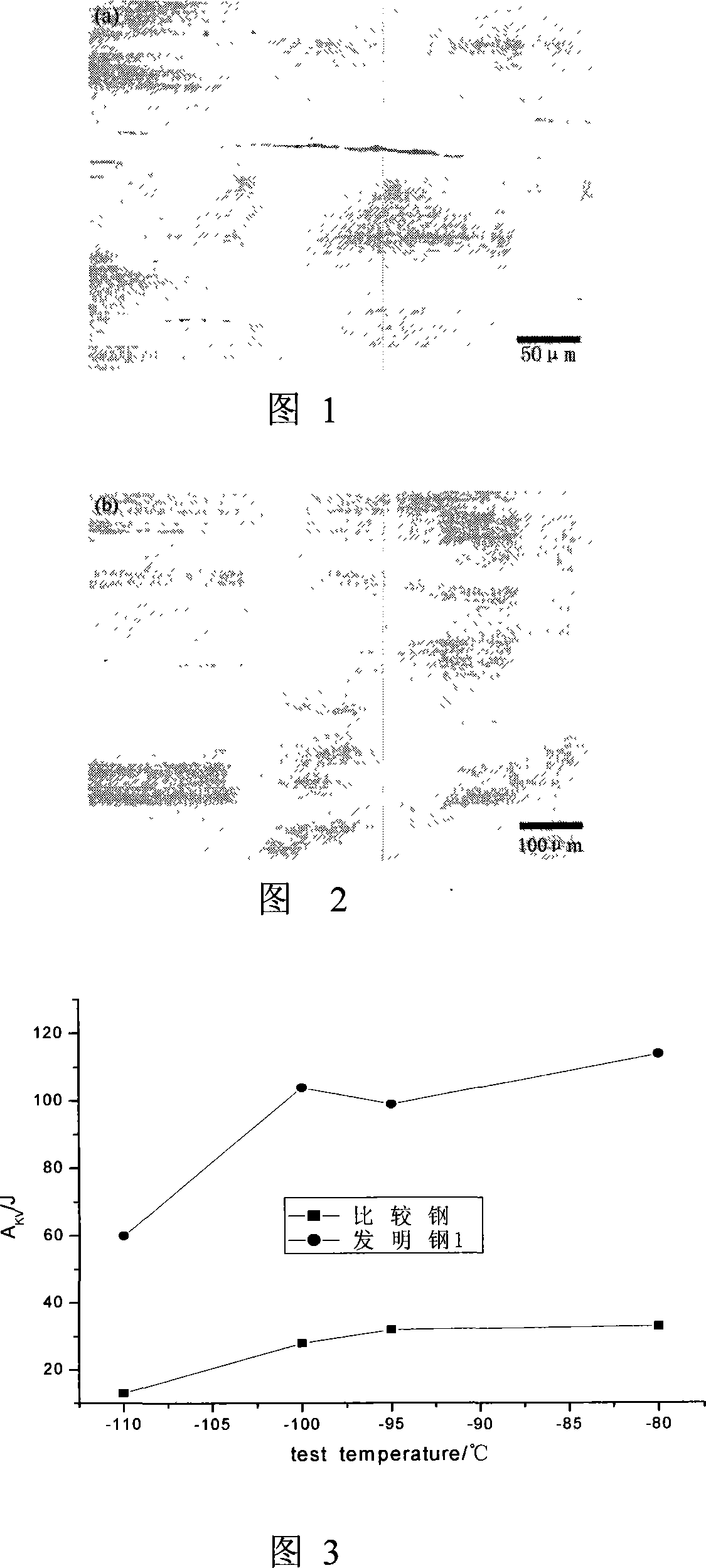

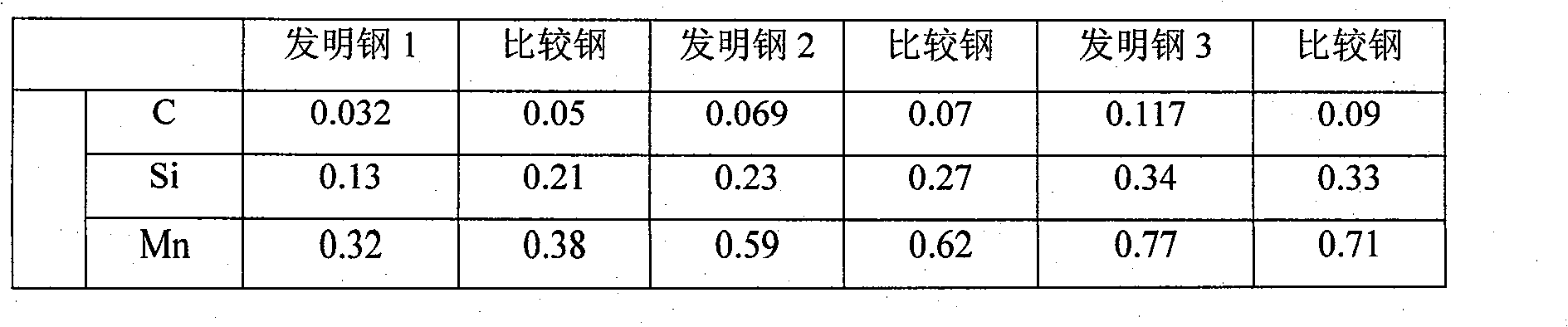

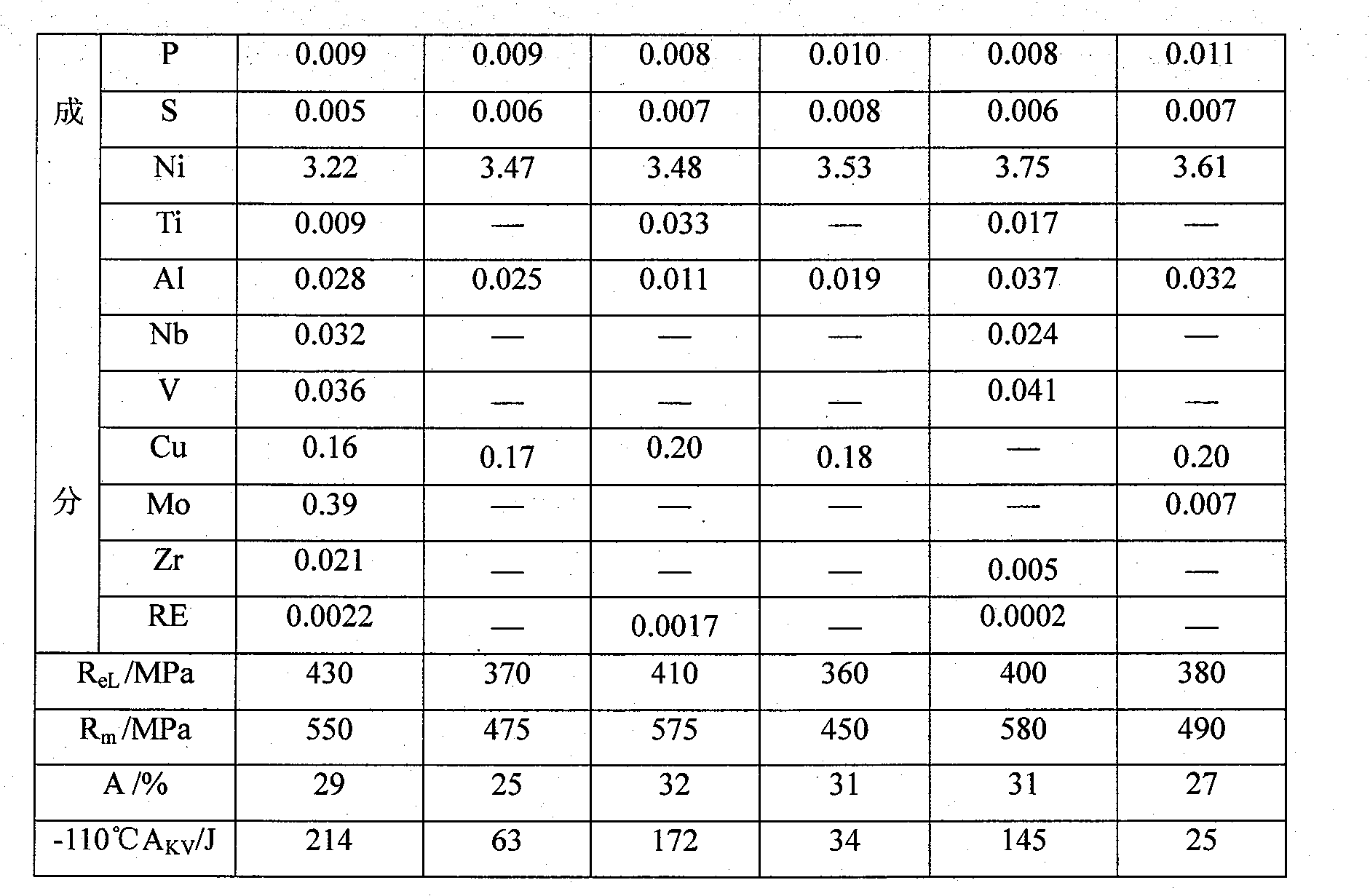

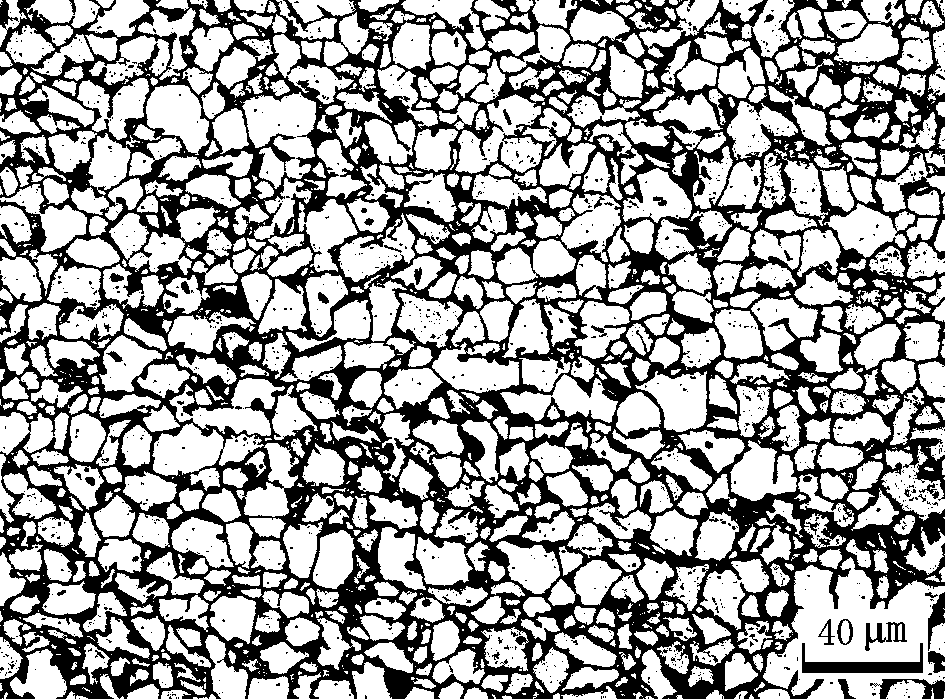

High ductility negative 110 degree low-temperature steel and manufacturing method thereof

InactiveCN101235466BStable and excellent low temperature toughnessExcellent -110℃ low temperature toughnessMetal rolling arrangementsReduction rateToughness

The invention relates to high toughness -110 DEG C low temperature steel and a method for manufacturing the low temperature steel, the steel is composed of components with following weight percent: C 0.02-0.12, Si 0.10-0.35, Mn 0.30-0.80, P<=0.015, S<=0.010, Ni 3.20-3.80, Ti 0.005-0.05a and Al 0.005-0.10, the low temperature steel also comprises two or more than two of Nb<=0.050, V<=0.10, Cu<=2.0, Mo<=0.50, Zr<=0.040 and RE<=0.020, and allowance is Fe. The method for manufacturing comprises: coating anti-oxidation coating on the surface of casting billets and controlling proper technological parameter such as the initial rolling temperature of steel, the controlled rolling accumulated reduction rate, each operation secondary reduction rate for last three operations, the finish rolling temperature, the normalizing heat preservation temperature, the heat preservation time, the tempering heat preservation temperature and the like. The method has the advantages of pure steel quality, stable organization, stable and excenlent-110DEG C low temperature toughness, simple technique and low cost, and is beneficial for extending and applying.

Owner:武汉钢铁有限公司

Steel plate for mid-temperature hydrogen-containing pressure container and manufacturing method of steel plate

InactiveCN108914016AImprove mechanical propertiesNo reduction in fracture toughnessSheet steelHydrogen

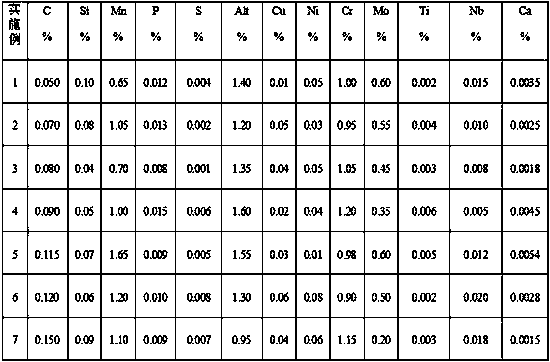

The invention discloses a steel plate for a mid-temperature hydrogen-containing pressure container and a manufacturing method of the steel plate. The steel plate for the mid-temperature hydrogen-containing pressure container comprises the following components in percentage by weight: 0.050-0.150% of C, no more than 0.10% of Si, 0.60-1.65% of Mn, no more than 0.015% of P, no more than 0.008% of S,0.90-1.60% of Alt, 0.01-0.06% of Cu, 0.01-0.08% of Ni, 0.90-1.20% of Cr, 0.20-0.60 % of Mo, no more than 0.006% of Ti, no more than 0.020% of Nb, no more than 0.0055% of Ca, and the balance Fe and inevitable impurities, wherein the contents the above elements have to meet the following relations: the quotient of the sum of Cr and Mo divided by C is greater than or equal to 8 and less than or equalto 25; and the sum of 54Al, 156 divided by Cr, and 96Mo is greater than or equal to 208 and less than or equal to 331.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

Full-automatic temperature-controlled and humidity-controlled heat pump dried persimmon drying equipment and drying technology

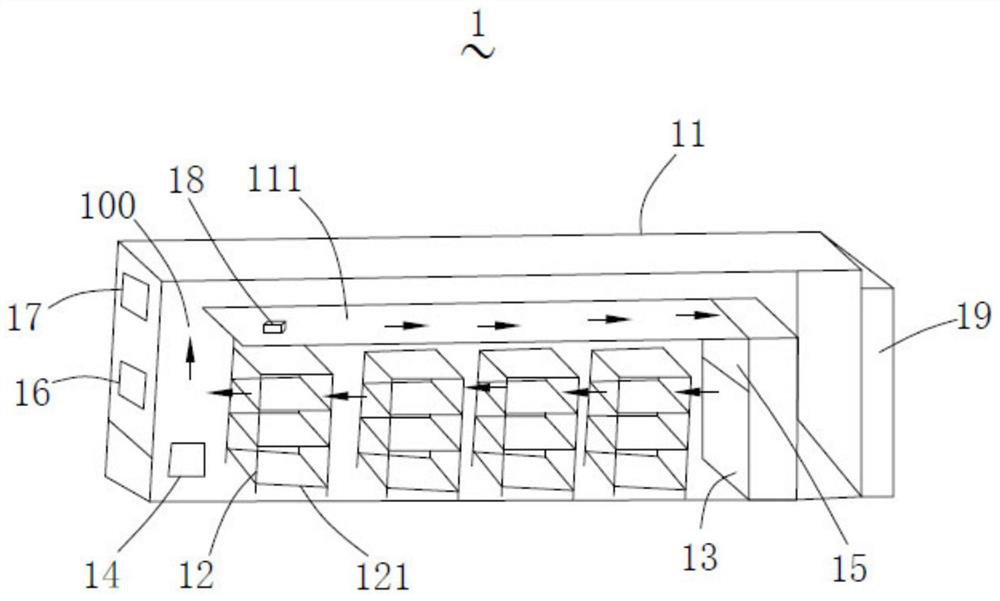

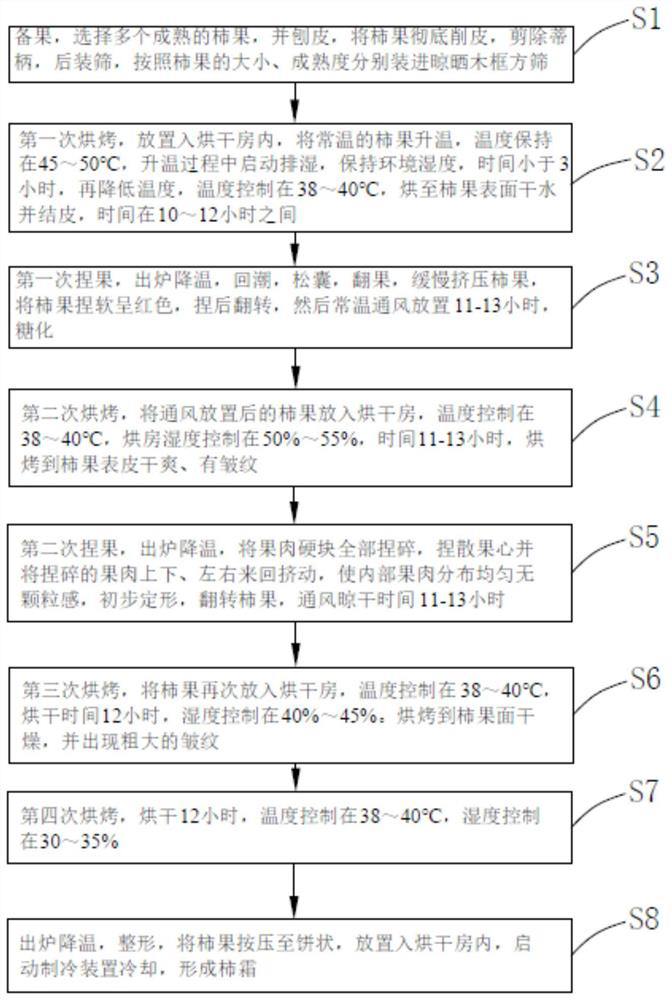

PendingCN112556330AIncrease productivityShorten drying timeFood processingDrying gas arrangementsEngineeringProcess engineering

The invention relates to the field of dried persimmon drying equipment, and particularly discloses full-automatic temperature-controlled and humidity-controlled heat pump dried persimmon drying equipment and a drying technology. A drying room is arranged and used for containing dried persimmons, and the temperature and humidity in the drying room are automatically controlled through a dehumidifierand a drying device so as to provide drying environments under different drying requirements, each drying step in the dried persimmon forming process is completed in the drying room, that is, on thebasis of the full-automatic temperature-controlled and humidity-controlled heat pump dried persimmon drying equipment, the dried persimmon drying process is completed through drying in the equipment and is not influenced by weather and climate in a traditional airing mode, the production efficiency of the dried persimmons is greatly improved, and the large-batch production requirement of the market is met. Meanwhile, by means of the equipment drying mode, the dried persimmon airing time is shortened, and the dried persimmon production efficiency is further improved.

Owner:广西天雨农业科技有限公司

Local gilding technology for commemorative coin (badge)

ActiveCN102618898AImprove stabilityGood repeatabilityPhotomechanical apparatusElectricityEngineering

The invention relates to a technology. The technology comprises the following steps: making a negative electronic manuscript Fiering sheet with a refined gild pattern, printing down it, modulating a printing material, carrying out color painting, coating the printing material on other parts which are not gilded, naturally air-drying the painting material, gilding, carrying out electrolytic oil removal to remove the printing material, and drying. The smallest precision of the pattern obtained through the refined pattern local gilding technology can reach 0.10mm, so local refined pattern gild on the mirror surface and the sand surface of a commemorative coin (badge) can be realized, and simultaneously the local refined pattern gild on the plane and the embossment of the commemorative coin (badge) can also be realized. The refined pattern local gild technology has the advantages of good stability and repeatability, and good reliability, and is adapted to large production requirements.

Owner:SHANGHAI MINT +1

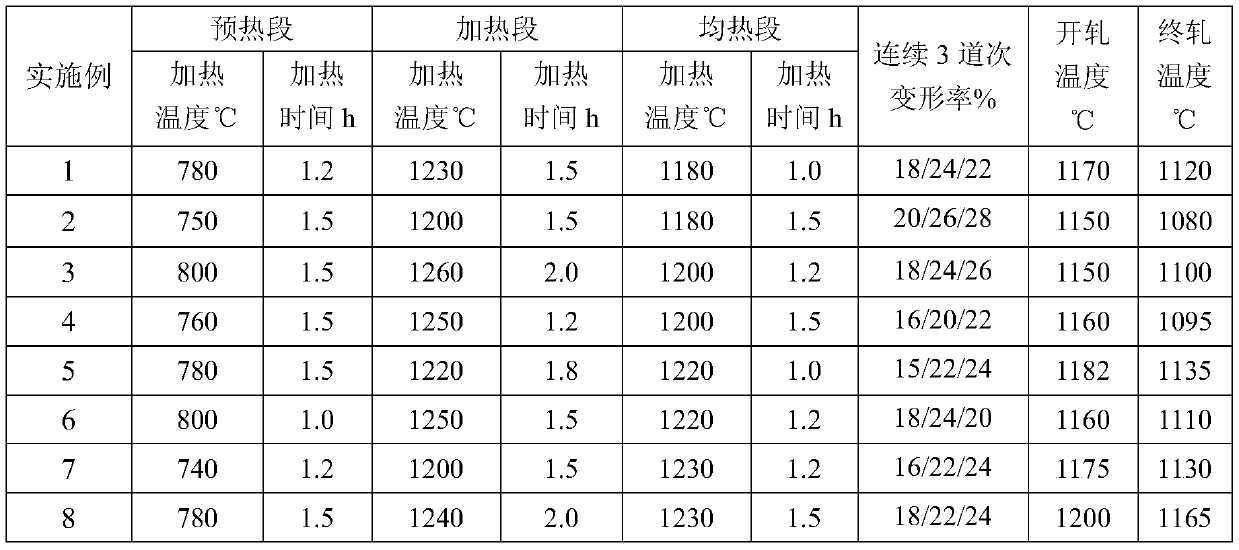

Preparation method of welding steel plate with large energy input

The invention discloses a preparation method of a welding steel plate with large energy input. The steel plate comprises C, Mn, Si, Ni, Cr, V, Ti, P, S, O, Als, Ca and Fe. The preparation method comprises following steps of: desulfurizing molten steel, smelting in a converter or an electric furnace, blowing bottom argon to a steel ladle or a ladle furnace to perform refining, performing continuous casting and rolling to obtain a plate, wherein ferrovanadium, ferronickel and ferrotitanium are added together with waste steel at first during the smelting step in the converter or the electric furnace; ferrochromium and calcium wires are added during the refining step so that chemical components in the steel satisfy requirements of components of the steel plate; the temperature of the molten steel added into a crystallizer during the continuous casting step is controlled to be 1530-1550 DEG C; and in the rolling step, the starting rolling temperature is 1200-1220 DEG C, the accumulated reduction rate of last three controlled rolling steps is not less than 42%, and the finish rolling temperature is 880-900 DEG C.

Owner:无锡市锡山区鹅湖镇荡口青荡金属制品厂

High energy welded high toughness steel for resisting corrosion of molten zinc and its preparing process

A high-toughness steel welded with high linear energy (More than 50 KJ / cm) and resisting molten zinc corrosion is prepared through converter smelting at 1250-1320 deg.C, vacuum treating, and rolling at 1000-1180 deg.c or lower than 950 deg.C and cumulative drafts rate is greater than or aqual to 50%. It features that composite Ti oxide is used to resist high linear energy, the Nb, V, etc. and used for raising strength, and the Cu, Ni, B and RE are used to resist molten zinc corrosion. Its advantages are simple technology with high efficiency, low cost, and high performance of finished steel.

Owner:武钢集团有限公司

Supporting steel for containment vessel of nuclear power station and manufacturing method thereof

InactiveCN111363985AGuaranteed toughness indexGuaranteed performanceNuclear powerProcess engineering

The invention provides supporting steel for a containment vessel of a nuclear power station and a manufacturing method thereof. The steel comprises the following components in percentage by weight: 0.10%-0.16% of C, 0.25%-0.45% of Si, 1.40%-1.65% of Mn, 0.45%-0.65% of Ni, 0.20%-0.50% of Cr, 0.20%-0.55% of Mo, 0.02%-0.04% of Alt, 0.05%-0.10% of Cu, 0.03-0.05% of V, 0.005-0.020% of Ti, 0.008% or less of P, 0.005% of less of S, 0.010% or less of N, and the balance being Fe and unavoidable impurities. The manufacturing method comprises smelting, continuous casting, heating, rolling and heat treatment. The thickness of a steel plate produced from the steel is 30-80 mm, the steel plate in the quenched and tempered state, simulated post-weld heat treatment state and 200 DEG C high temperature state completely meets the requirements of technical indicators, and meanwhile -40 DEG C impact absorption energy is still remained at a high level.

Owner:ANGANG STEEL CO LTD +1

Manufacturing method for rolling special shape at groove of edge part of coin or commemorative medallion

ActiveCN103504733AChange the status quo of single production technologyEasy to viewMedalBadgesCircular discStructural engineering

The invention discloses a manufacturing method of a coin, particularly relates to a coin or commemorative medallion manufacturing method for rolling a special shape at a groove of an edge part of the coin or a commemorative medallion. The manufacturing method for rolling the special shape at the groove of the edge part of the coin or the commemorative medallion comprises the following steps: a, processing a special-shaped electrode according to designed parameters; b, processing a chip blank; c, fixing the special-shaped electrode and the chip blank on an electric spark forming machine by a clamp, and then processing out a chip by the electric spark forming machine; d, processing an upper clamping plate and a lower clamping plate; e, combining the upper clamping plate and the lower clamping plate with the chip to form a bending plate; f, processing a disc; g, fixing the disc and the bending plate on a side trimming machine, and through metal extrusion forming, forming a groove special shape at the edge part of the side-trimmed blank cake; and h, stamping and forming, and thus obtaining the coin or commemorative medallion having the edge part with the groove rolled with the special shape. The method improves appreciation, collection and anti-falsification of the coin or the commemorative medallion.

Owner:沈阳中钞造币技术研究有限公司

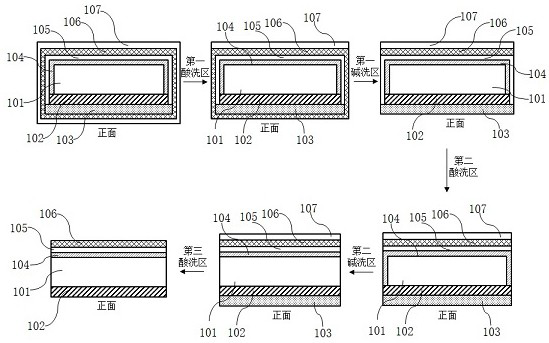

Chain type wet etching equipment for TOPCon battery

ActiveCN112185865AImprove production continuityImprove conversion efficiencyFinal product manufactureSemiconductor/solid-state device manufacturingHydrofluoric acidEtching

The invention discloses chain type wet etching equipment for a TOPCon battery. The chain type wet etching equipment comprises five functional areas and a conveying device penetrating through each functional area; the five functional areas are a first acid washing area, a first alkali washing area, a second acid washing area, a second alkali washing area and a third acid washing area; solutions ofthe first acid washing area, the second acid washing area and the third acid washing area are hydrofluoric acid solutions; solutions of the first alkali washing area and the second alkali washing areaare sodium hydroxide or potassium hydroxide solutions; and a to-be-etched silicon wafer sequentially passes through the first acid washing area, the first alkali washing area, the second acid washingarea, the second alkali washing area and the third acid washing area through the conveying devices. According to the chained wet etching equipment, an edge is isolated while winding polycrystalline silicon is removed, so that the production continuity of a TOPCon battery is realized, and meanwhile, the conversion efficiency of the battery is improved; the equipment is high in automation degree, high in productivity and suitable for large-scale production requirements; and the equipment is easy to realize and low in cost.

Owner:CHANGZHOU SHICHUANG ENERGY CO LTD

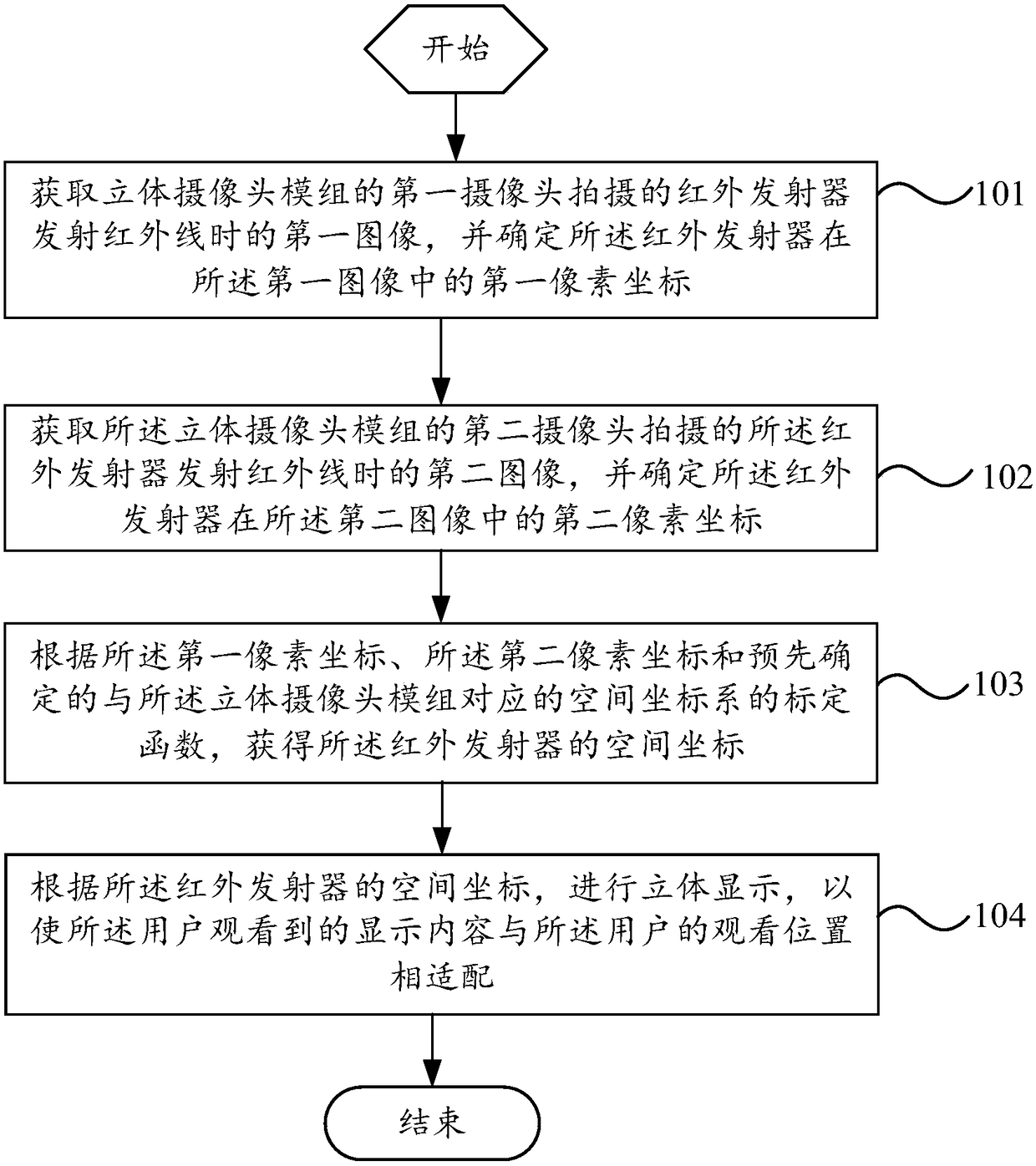

Naked-eye three-dimensional display method and device

ActiveCN108616753AAccurately grasp the positioning accuracyImprove standardizationSteroscopic systemsCamera moduleCalibration function

The invention provides a naked-eye three-dimensional display method and device. The naked-eye three-dimensional display method comprises the steps of acquiring a first image and a second image shot bya three-dimensional camera module when an infrared emitter emits infrared rays, and determining a first pixel coordinate of the infrared emitter in the first image and a second pixel coordinate of the infrared emitter in the second image, wherein the space position of the infrared emitter is changed along with the change of the watching position of a user; obtaining the spatial coordinate of theinfrared emitter according to the first pixel coordinate, the second pixel coordinate and a preset calibration function of a spatial coordinate system corresponding to the three-dimensional camera module; carrying out three-dimensional display according to the spatial coordinate of the infrared emitter, so that the display content viewed by the user is matched with the watching position of the user. The problem that the positioning accuracy is difficult to control due to the fact that the inner reference and the outer reference of a camera are used for watching position positioning is solved.

Owner:SUPERD CO LTD

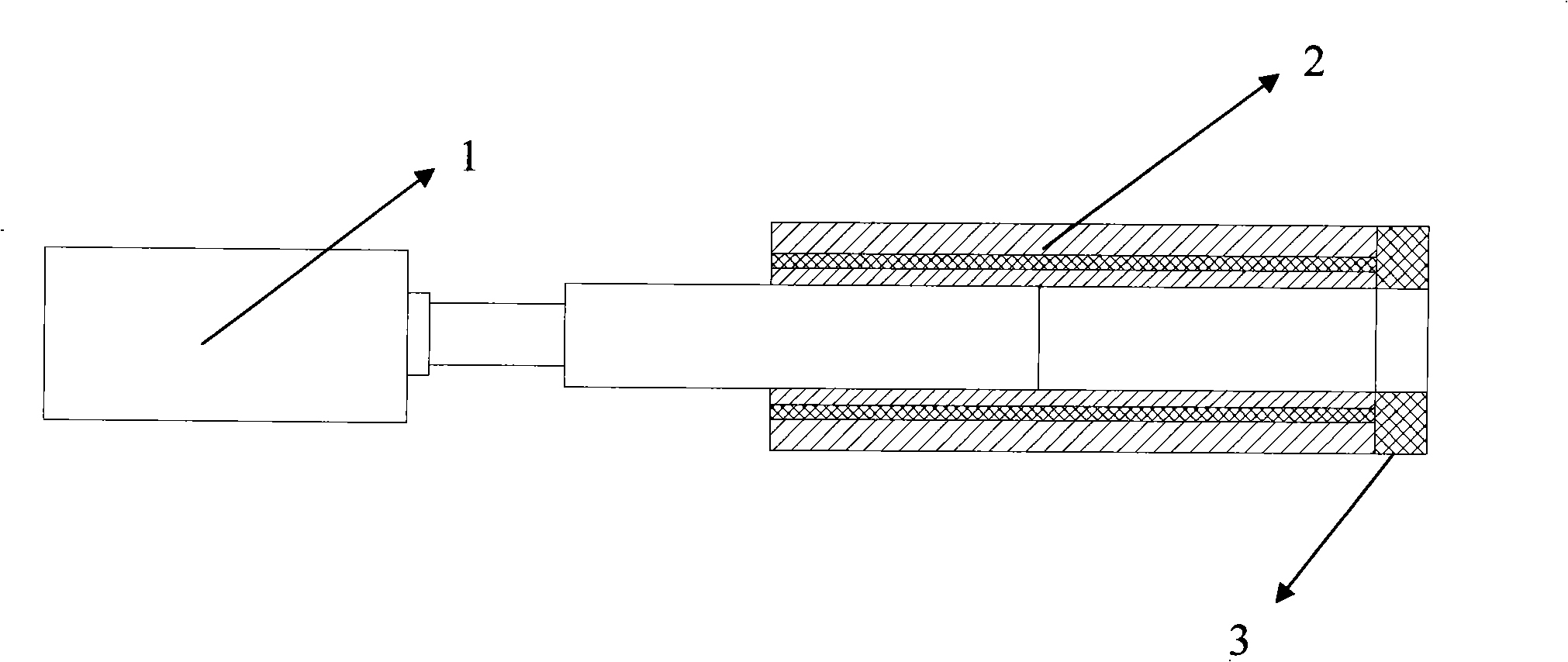

Equipment for producing cuprum-cladding-aluminium composite wire

InactiveCN101303922AImprove bindingSimple structureCable/conductor manufactureHydraulic cylinderFixed frame

The invention discloses a device for preparing a copper cladding aluminum composite wire, which is characterized in that the device is provided with a horizontal hydraulic driving device (1) and a tubular fixing frame (2) which is arranged at the output shaft direction of a hydraulic cylinder and a retaining ring ((3) which is arranged at the end of the tubular fixing frame (2). The device is suitable for making large sized copper cladding aluminum wires, intensively processed copper cladding aluminum lines and other special shaped copper cladding aluminum wires. The device is simple in structure, convenient in operation, high in production efficiency and suitable for mass production.

Owner:ZIRUIDA NEW MATERIAL SCI TECH DEV DALIAN

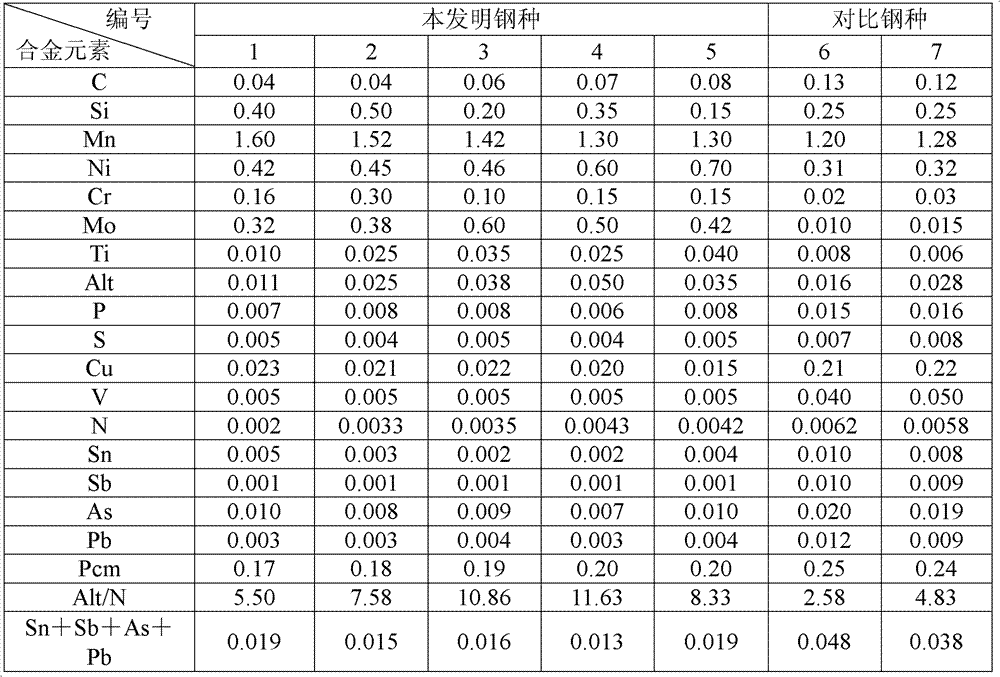

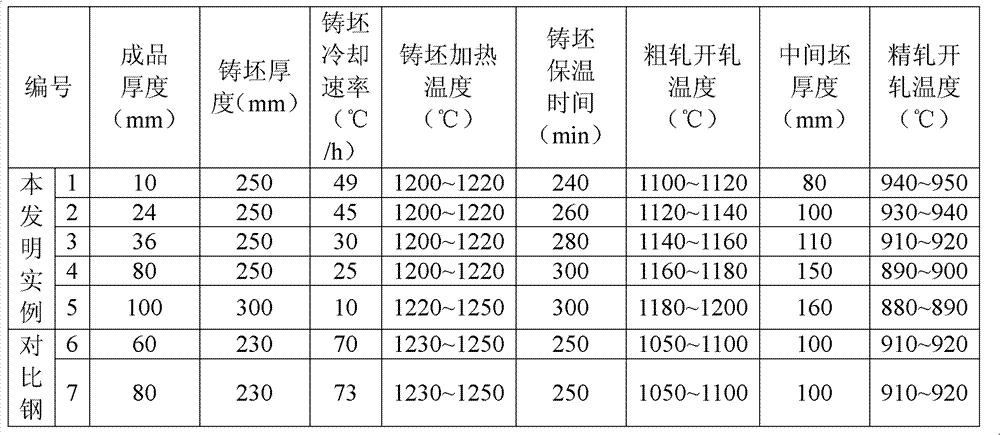

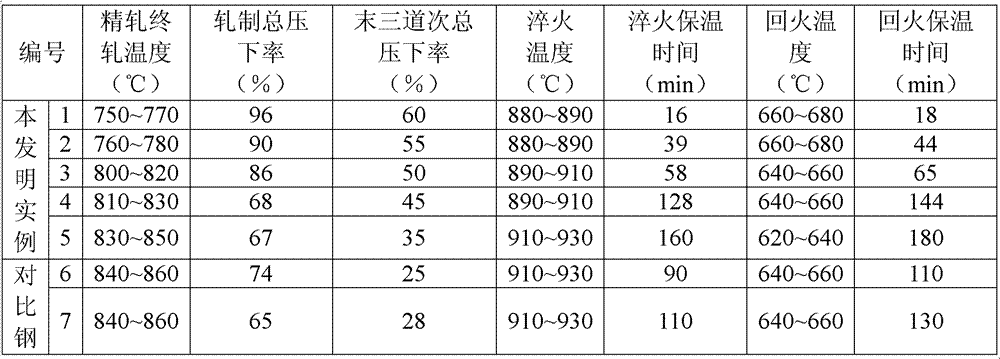

Nuclear container steel with tensile strength of more than 690MPa level and production method

The invention discloses a nuclear container steel with tensile strength of more than 690MPa level and a production method. The steel comprises the following chemical components in percentage by weight: less than or equal to 0.08 percent of C, 0.15 to 0.50 percent of Si, 1.30 to 1.60 percent of Mn, 0.01 to 0.05 percent of Alt, 0.42 to 0.70 percent of Ni, 0.32 to 0.60 percent of Mo, 0.10 to 0.30 percent of Cr, 0.01 to 0.04 percent of Ti, less than or equal to 0.008 percent of P, less than or equal to 0.005 percent of S, less than or equal to 0.005 percent of N, less than or equal to 0.03 percent of Cu, less than or equal to 0.007 percent of V, less than or equal to 0.005 percent of Sn, less than or equal to 0.005 percent of Sb, less than or equal to 0.010 percent of As, less than or equal to 0.005 percent of Pb, and the balance of Fe and inevitable impurities, wherein P, S, N, Cu, V, Sn, Sb, As and Pb are used as controlled elements. The production method comprises the following steps of: smelting clean steel, performing continuous casting, cooling casting blank to room temperature, heating the casting blank, performing heat preservation, rough rolling and finish rolling, quenching,tempering, and naturally cooling to room temperature. The steel can improve the safety and the reliability in the operation of a nuclear power plant, and has the advantages of high strength, low welding crack sensitivity, low radiation embrittlement effect and excellent tensile property and welding property at the temperature of 20 DEG C below zero.

Owner:武钢集团有限公司

Production method of steel applied to high strength huge line energy welded ship

The invention discloses a production method of steel applied to a high strength huge line energy welded ship. The steel is composed of C, Mn, Si, Ni, Cr, V, Ti, P, S, O, Als, Mo, Fe and unavoidable impurities. The preparation method comprises the steps of liquid steel desulfurization treatment, converter or electric furnace smelting, ladle furnace or ladle argon blowing refining, continuous casting and rolling into a plate, wherein when converter or electric furnace smelting is carried out, ferrovanadium, ferronickel and ferrotitanium are added with scrap in front of a furnace. During a refining process, chromium and molybdenum are added, so that the chemical compositions in the steel meet the composition requirements of the steel plate. When continuous casting is carried out, the temperature of liquid steel coming into a crystallizer is controlled at the temperature of 1530 to 1550 DEG C. When rolling into the plate is carried out, the rolling starting temperature is 1200 to 1220 DEG C; the controlled rolling end three cumulative reduction rate is no less than 42%; and the rolling finishing temperature is 880 to 900 DEG C.

Owner:WUXI JINDANG MACHINERY FACTORY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com