High ductility negative 110 degree low-temperature steel and manufacturing method thereof

A manufacturing method and high-toughness technology, applied in metal rolling and other directions, can solve the problem of only -40°C, and achieve the effects of stable structure, reduced production cost, and excellent low-temperature toughness

Inactive Publication Date: 2011-06-22

武汉钢铁有限公司

View PDF2 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The low temperature impact test temperature of the above patents is only -40°C

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0034] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

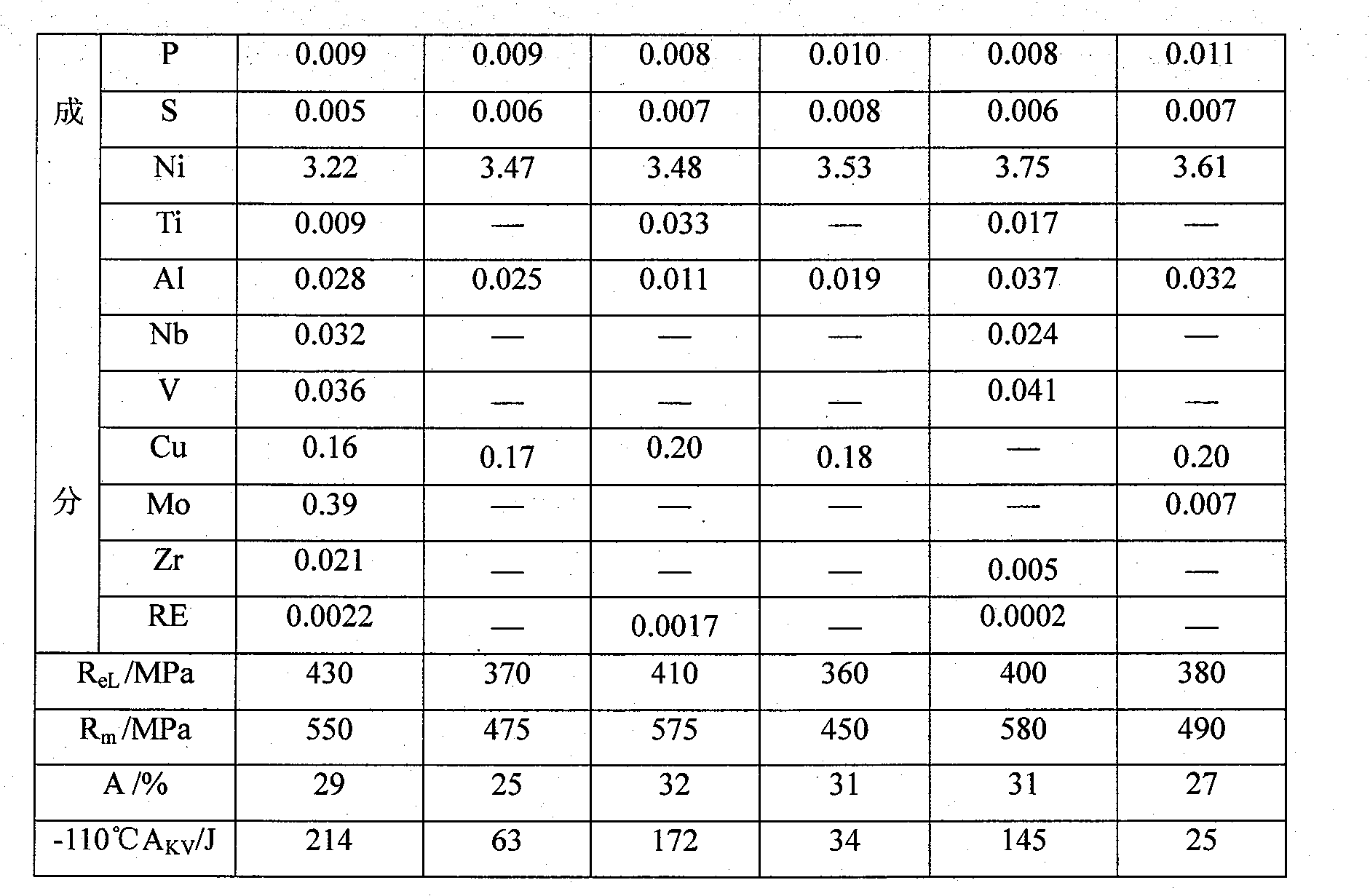

The invention relates to high toughness -110 DEG C low temperature steel and a method for manufacturing the low temperature steel, the steel is composed of components with following weight percent: C 0.02-0.12, Si 0.10-0.35, Mn 0.30-0.80, P<=0.015, S<=0.010, Ni 3.20-3.80, Ti 0.005-0.05a and Al 0.005-0.10, the low temperature steel also comprises two or more than two of Nb<=0.050, V<=0.10, Cu<=2.0, Mo<=0.50, Zr<=0.040 and RE<=0.020, and allowance is Fe. The method for manufacturing comprises: coating anti-oxidation coating on the surface of casting billets and controlling proper technological parameter such as the initial rolling temperature of steel, the controlled rolling accumulated reduction rate, each operation secondary reduction rate for last three operations, the finish rolling temperature, the normalizing heat preservation temperature, the heat preservation time, the tempering heat preservation temperature and the like. The method has the advantages of pure steel quality, stable organization, stable and excenlent-110DEG C low temperature toughness, simple technique and low cost, and is beneficial for extending and applying.

Description

technical field [0001] The present invention relates to a steel and its manufacturing method. Background technique [0002] Prior to the present invention, Chinese Patent Publication Nos. CN98807689.6 and CN96190145.4 respectively disclosed "weldable ultra-high-strength steel with excellent ultra-low temperature toughness" and "high-strength trunk pipe steel with low yield ratio and excellent low-temperature toughness" , the Ni content of the involved steel ranges from 0.2 to 1.0%, and the low temperature impact test temperature is -40°C. Another example is the Japanese patent JP592643201, which discloses "a production method of high-strength steel plate for low temperature use". By performing hot rolling, cooling and heat treatment on low-alloy steel containing 1.0-4.0% Ni, excellent low-temperature toughness at -40°C is obtained. . The temperature of the low-temperature impact test of the above-mentioned patents is only -40°C. Contents of the invention [0003] The pu...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C22C38/16B21B1/26

Inventor 习天辉陈晓郭爱民柳志敏段东明刘吉斌李建华丁庆丰卜勇董中波童明伟刘继雄

Owner 武汉钢铁有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com