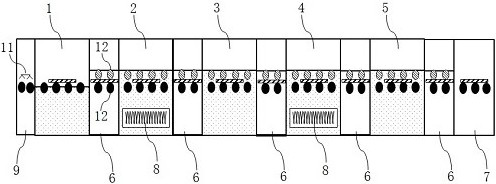

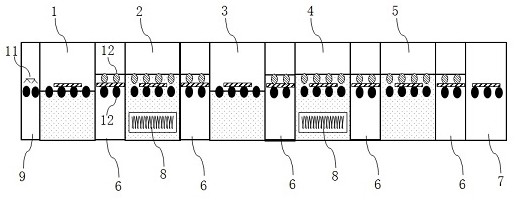

Chain type wet etching equipment for TOPCon battery

A wet etching and chain technology, applied in circuits, electrical components, sustainable manufacturing/processing, etc., can solve the problems of inability to continuously realize equipment, complicated process switching procedures, and low degree of automation, and achieve continuous production. , high degree of automation, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

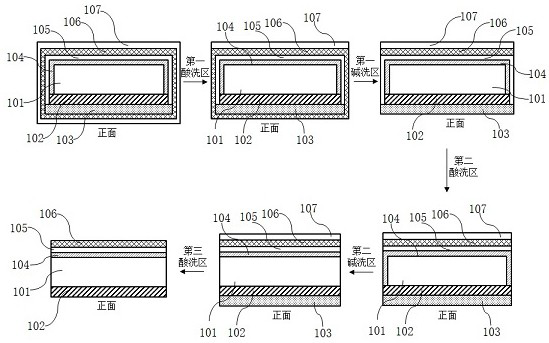

[0029] Such as image 3 and Figure 4 , in the TOPCon cell fabrication process, boron-doped layer 102 is formed after boron is diffused on the front side of silicon substrate 101, a mask layer 103 with a thickness of about 10-300 nm is deposited on the surface of boron-doped layer 102, and a layer with a thickness of about 0.5 nm is deposited on the back side. ~3nm tunneling oxide layer 105, on which an intrinsic amorphous silicon layer is deposited, and then the intrinsic amorphous silicon layer is crystallized into a phosphorus-doped polysilicon layer 106 by phosphorus diffusion annealing, and at the same time, the phosphorus-doped polysilicon layer 106 A PSG (phosphosilicate glass) layer 107 with a thickness of about 1-40 nm is formed on the surface. During this process, the tunneling oxide layer 105 will form a wrap-arou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com